16

Regulator and hose replacement

The pressure regulator and hose assembly supplied with the unit must be used. If

replacements are needed, contact customer care at dcsappliances.com.

Resetting the flow control

Failure to follow the steps in the order shown may cause the Flow Limiting Device to

activate resulting in extremely low gas flow and irregular operation.

1

All dials must be in the

OFF

position.

2

Attach regulator hose assembly to the tank and open the LP tank valve (minimum of

two full turns).

Stainless Steel

Always use the mildest cleaning method first. Do not use steel wool to clean the product as

it will scratch the surface.

Burner trivets

For durability and optimal performance, the burner trivets have been crafted using Stainless

Steel. It is recommended that the trivets are cleaned while in place, however if removing

the trivets take care as they are heavy and ensure they are placed on a protected surface.

Trivets can be cleaned using hot soapy water.

Due to rapid temperature changes the Stainless Steel will slowly darken over time. This is

normal and will not impact the products performance.

Drip tray

To clean the drip tray, pull tray forward to remove. Wipe spills as soon as possible to

prevent them becoming baked on.

Cleaning burner parts

3

Ensure all burner dials are

OFF

and all surfaces are cool.

4

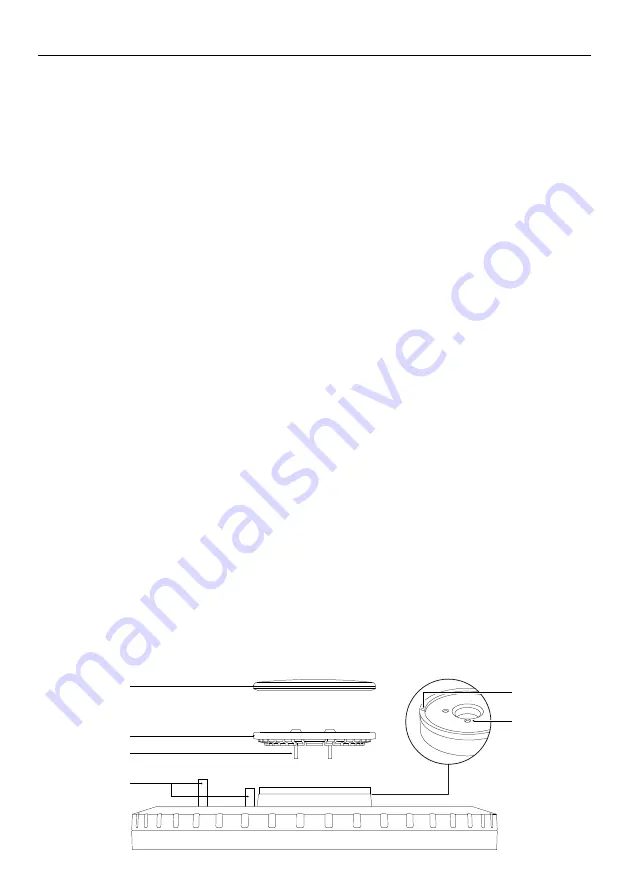

Remove the burner cap and port ring and wash in hot soapy water, rinse and dry. The

burner ports can be cleaned using a bristled brush.

Do not disassemble the burner, doing so could result in a fire hazard or explosion.

5

After cleaning, ensure the locating pins are correctly aligned. Incorrect alignment can

cause poor burner performance and uneven or irregular flames.

Cap

Port ring

Igniter

Locating pins

Locating holes

Locating notch

CARE AND CLEANING