11

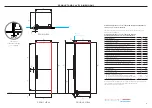

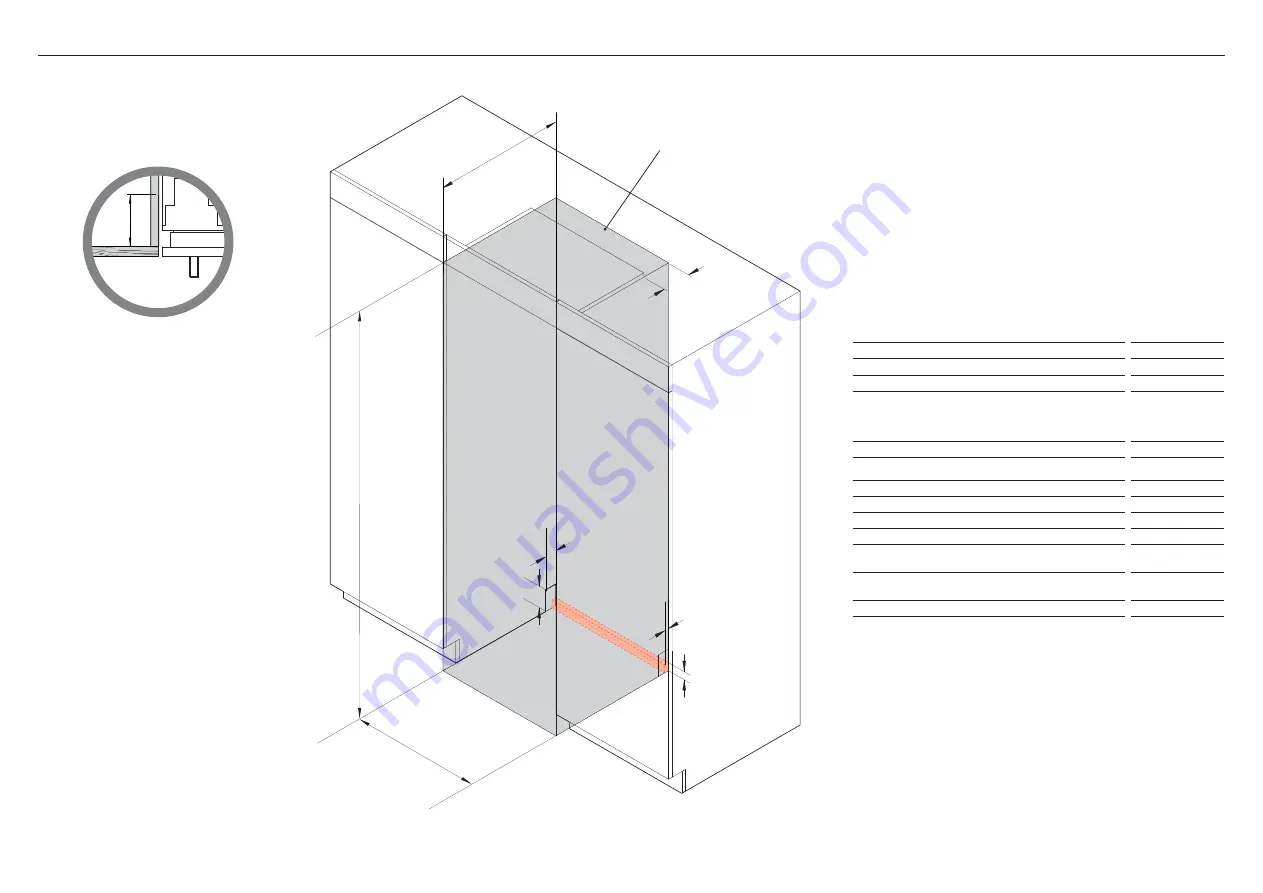

CAVITY PREPARATION

NOTE: Left hand hinge is a mirrored version of the image shown.

For ease of installation, ensure cavity has consistent dimensions top to bottom and left

to right.

Minimum Cavity Dimensions

in

mm

a

Overall height of cavity

74

1880

B

Overall width of cavity

23 5/8

600

c

Minimum overall depth of cavity:

• When services are located outside of cavity (shallow)

• When services are located in the cabinet above the cavity

• When services are located at rear of cavity (deep)

23 5/8

24

25 9/16

600

610

650

Minimum required finished return

4

100

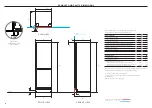

Electrical / Plumbing Supply Dimensions

in

mm

d

Overall height of supply routing area at rear of cavity

1 7/16

37

Overall width of supply routing area at rear of cavity

23 5/8

600

E

Overall depth of supply routing area at rear of cavity

13/16

20

F

Height of notch at rear of cavity for services to be routed into

adjacent cabinet (either side)

4

100

G

Depth of notch at rear of cavity for services to be routed into

adjacent cabinet (either side)

2 3/16

55

H

Minimum depth above cavity for services to be routed through

2 3/16

55

Recommended that services are routed to the adjacent cabinet or either side of

the product.

Dimensions may vary by ± 1/16’’ (2mm)

ALTERNATIVE AREA

ABOVE CAVITY FOR

ELEC / WATER CONNECTION

B

C

A

D

E

ISO VIEW

G

F

H

FINISHED RETURN

CAVITY SIDES & TOP

4"