24

!3

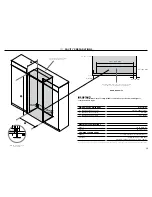

ASSEMBLE DOOR PANEL SET

The assembly of Fisher & Paykel kits (EZKleen stainless steel door panels) and custom door panels are outlined below. For Fisher & Paykel kits, only remove the protective film for handle

installation. This will protect the finish of the door panels until installation is complete.

1

Mounting handle

(refer to

A

)

For Fisher & Paykel door panel sets,

remove the plastic plugs from the handle

holes x4. Align the handle to the holes and

secure with screw handle x4 (M5 x 25 pan

head socket screws).

For custom panels, ensure handle is

secured 2 9/16” (65 mm) from the inner edge

of the panel to the center – this will avoid

interference with bracket installation.

2

Hanging bracket

(refer to

B

)

For Fisher & Paykel door panel sets, align

the bracket to the holes and secure with

screws x4 (M5 x 14 Mush Phillips SS).

For custom panels, secure bracket with

screws x4 (#8 x 16 Mush washer screws).

3

Side brackets and straps

(refer to

C

)

For Fisher & Paykel door

panel sets, align bracket

and strap to the holes

on the side of the

panel and secure

with screws x2

(M5 x 14 Mush

Phillips SS).

For custom

panels, secure

bracket with

screws x2 (#8 x 16

Mush washer screws).

Repeat this process for all

brackets and straps, and remaining

French door panel.

C

A

B

French door panels

Drawer door panel

4

Mounting handle

(refer to

D

)

For Fisher & Paykel door panel sets,

remove the plastic plugs from the

handle holes x4. Align the handle to the

holes and secure with screw handle x4

(M5 x 25 pan head socket screws).

For custom panels, ensure handle screw

heads are counter sunk into the back

of the panel to avoid interference with

hanging bracket.

5

Hanging bracket

(refer to

E

)

For Fisher & Paykel door panel sets, align

the bracket to the holes and secure with

screws x6 (M5 x 14 Mush Phillips SS).

For custom panels, secure bracket with

screws x6 (#8 x 16 Mush washer screws).

6

Side brackets and straps

(refer to

F

)

For Fisher & Paykel door panel sets,

align bracket and strap to the holes on

the side of the panel and secure with

screws x2 (M5 x 14 Mush Phillips SS).

For custom panels, secure bracket

with screws x2 (#8 x 16 Mush washer

screws).

Repeat this process for all brackets

and straps.

D

E

F