Summary of Contents for RX256DT4X1

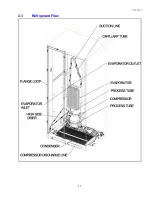

Page 11: ...321023 11 2 3 Refrigerant Flow...

Page 12: ...321023 12 2 4 Cabinet Air Flow...

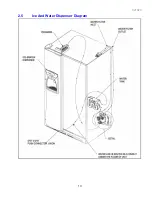

Page 13: ...321023 13 2 5 Ice And Water Dispenser Diagram...

Page 14: ...321023 14 2 6 Water Valve Diagram...

Page 15: ...321023 15 2 7 Typical External Sweat Pattern...

Page 16: ...321023 16 3 INSTALLATION...

Page 17: ...321023 17...

Page 18: ...321023 18...

Page 76: ...321023 76 Ice Water Dispensing Board...

Page 78: ...321023 78 Mid Electronic Specification Control RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 104: ...321023 104 14 WIRING DIAGRAMS 14 1 Wiring Schematic RX256DT7X1...

Page 105: ...321023 105 14 2 Wiring Diagram RX256DT7X1...

Page 106: ...321023 106 14 3 Wiring Schematic RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 107: ...321023 107 14 4 Wiring Diagram RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 108: ...321023 108 NOTES...