321023

87

12

SEALED SYSTEM DIAGNOSIS

CONDITION Suction

pressure

variation

from

normal

Head

pressure

variation

from

normal

T1 inlet

temperature

variation from

normal

T2 outlet

temperature

variation from

normal

T3 suction

temperature

variation from

normal

Wattage

variation

from

normal

Refrigerant

Overcharge

Increase Increase Warmer

Warmer

Colder

Increase

Shortage of

Refrigerant

Decrease Decrease or

Increase

See Text

Colder Warmer Warmer

Decrease

Partial

Restriction

Decrease Decrease or

Increase

See Text

Note 2

Colder Warmer Warmer

Decrease

Air in

System

Near

Normal

Increase Warmer Warmer

Warmer Increase

Low Ambient

Installations

(High

Ambients

the

Decrease Decrease

Colder

Warmer

Warmer

Decrease

Additional

Heat Load

Increase

Increase Warmer Warmer

Warmer Increase

Inefficient

Compressor

Increase Normal

or

Decrease

Warmer or

Colder

Warmer Warmer

Decrease

12.1

Symptoms of an Overcharge

•

Above normal freezer temperatures.

•

Longer than normal or continuous run.

•

Freezing in fresh food compartment, especially on forced air meat keeper models.

•

Higher than normal suction and head pressure.

•

Higher than normal wattage.

•

Evaporator inlet and outlet temperatures warmer than normal.

•

Suction tube temperature below ambient. Always check for separated heat exchanger when

suction temperature is colder than ambient.

Various conditions could indicate an overcharge. For example, if the cooling coil is not defrosted at

regular intervals, due to a failure of the defrost system, the refrigerant will "flood out" and cause the

suction line to frost or sweat. The cause of this problem should be corrected rather than to purge

refrigerant from the system. Running the freezer section colder than necessary (-2 to -1

O

F is

considered normal package temperatures) or continuous running of the compressor for a variety of

reasons, or the freezer fan motor not running, may give the indication of an overcharge.

12.2

Symptoms of Refrigeration Shortage

•

Rise in food product temperature in both compartments. (See Note 1 below.)

•

Long or continuous run time.

•

Look for obvious traces of oil that would occur due to a leak or cracked refrigerant line.

•

Lower than normal wattage.

•

Compressor will be hot to touch because of the heat generated by the motor windings from long

continuous running. It will not be as hot as it would be with a full charge and long run times for

some other reason such as a dirty condenser.

Summary of Contents for RX256DT4X1

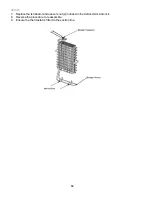

Page 11: ...321023 11 2 3 Refrigerant Flow...

Page 12: ...321023 12 2 4 Cabinet Air Flow...

Page 13: ...321023 13 2 5 Ice And Water Dispenser Diagram...

Page 14: ...321023 14 2 6 Water Valve Diagram...

Page 15: ...321023 15 2 7 Typical External Sweat Pattern...

Page 16: ...321023 16 3 INSTALLATION...

Page 17: ...321023 17...

Page 18: ...321023 18...

Page 76: ...321023 76 Ice Water Dispensing Board...

Page 78: ...321023 78 Mid Electronic Specification Control RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 104: ...321023 104 14 WIRING DIAGRAMS 14 1 Wiring Schematic RX256DT7X1...

Page 105: ...321023 105 14 2 Wiring Diagram RX256DT7X1...

Page 106: ...321023 106 14 3 Wiring Schematic RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 107: ...321023 107 14 4 Wiring Diagram RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 108: ...321023 108 NOTES...