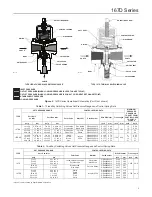

167D Series

6

the lines or from external sources. Switching

valves should be inspected for damage

periodically and after any overpressure condition.

2. Only personnel qualified through training and

experience should install, operate, and maintain

a switching valve. Make sure that there is no

damage to or foreign material in the switching

valve. Also ensure that all tubing and piping is

free of debris.

3. Install the switching valve to achieve the desired

switching results. Connect the control pressure

line to either D port. Verify that the other D port

is plugged. The port labeled “IN” or port A is the

common inlet connection and ports B and C are

the outlet connections. Flow is either from A to B

or A to C.

4. A clogged spring case vent hole may cause the

switching valve to function improperly. To keep

this vent hole from being plugged (and to keep

the spring case from collecting moisture, corrosive

chemicals, or other foreign material) orient the

vent to the lowest possible point on the spring

case or otherwise protect it.

Inspect the vent hole regularly to make

sure it is not plugged. Spring case vent

hole orientation may be changed by rotating the

spring case with respect to the body. A 1/4 NPT

spring case vent may be remotely vented by

installing obstruction-free tubing or piping into

the vent. Protect the remote vent by installing a

screened vent cap on the remote end of the

vent pipe.

5. For use in switching valve shutdown, install

upstream block and vent valves and downstream

block and vent valves (if required), or provide

some other suitable means of properly venting the

switching valves inlet and outlet pressures. Install

a pressure gauge to monitor instruments

on startup.

6. Apply a good grade of pipe compound to the

external pipe threads before making connections,

making sure not to get the pipe compound inside

the switching valves.

7. Install tubing fitting or piping into the threaded NPT

inlet connection on the body (key 1) and into the

threaded NPT outlet connections.

8. The 1/4 NPT control pressure ports must be

plugged if not in use.

Startup and Adjustment

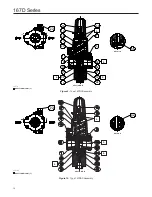

Key numbers are referenced in Figures 7 through 13.

1. With proper installation completed and downstream

equipment properly adjusted, slowly open the

upstream and downstream shut-off valve (when

used) while using pressure gauges to

monitor pressure.

!

WARNING

To avoid personal injury, property

damage, or equipment damage caused

by bursting of pressure containing parts

or explosion of accumulated gas, never

adjust the control spring to produce an

outlet pressure higher than the upper

limit of the outlet pressure range for that

particular spring. If the desired outlet

pressure is not within the range of the

control spring, install a spring of the

proper range according to the diaphragm

parts maintenance procedure.

2. If outlet pressure adjustment is necessary,

monitor outlet pressure with a gauge during the

adjustment procedure. The switching valve

is adjusted by loosening the hexnut (key 19),

if used, and turning the adjusting screw or

handwheel (key 18) clockwise to increase or

counterclockwise to decrease the outlet pressure

setting. Retighten the hexnut to maintain the

adjustment position.

Maintenance

Switching valve parts are subject to normal wear and

must be inspected and replaced as necessary. The

frequency of inspection and replacement of parts

depend on the severity of service conditions and

applicable codes and government regulations.

Note

If sufficient clearance exists, the body

(key 1) may remain mounted on other

equipment or in a line or panel during

maintenance unless the entire switching

valve will be replaced.