www.Fisher.com

Fisher

r

377 Trip Valve

Contents

Introduction

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Educational Services

3

. . . . . . . . . . . . . . . . . . . . . . . . .

Installation

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Pressure Requirements

5

. . . . . . . . . . . . . . . . .

Operating Information

8

. . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principle of Operation

10

. . . . . . . . . . . . . . . . . . . . . . . .

377D Trip Valve

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

377L Trip Valve

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

377U Trip Valve

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Periodic Operational Check

12

. . . . . . . . . . . . . . . . . . .

Trip Valve Part Replacement Procedures

13

. . . . . . . .

Replacing Diaphragms and Valve Plug Parts

13

. . . . .

Replacing Stem/Plug Assembly Parts

14

. . . . . . . . . . .

Parts Ordering

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

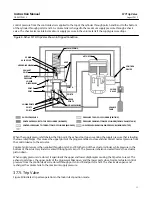

Figure 1. Fisher 377 Trip Valve Mounted on Size 130

585C Actuator

W8435‐1

Introduction

Scope of Manual

This instruction manual provides installation, operation, maintenance, and parts information for the Fisher 377 trip

valve. Refer to separate instruction manuals for information regarding the control valve, actuator, and accessories.

Do not install, operate, or maintain a 377 trip valve without being fully trained and qualified in valve, actuator and

accessory installation, operation, and maintenance.

To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all of the contents of this manual, including all safety cautions and warnings.

If

you have any questions regarding these instructions contact your Emerson Process Management sales office before

proceeding.

Description

377 pressure‐sensing trip valves, shown in figures 1, 2, and 3, are for control applications where a specific

valve/actuator action is required when supply pressure falls below a specific point. When supply pressure falls below

the trip point, the trip valve cause the actuator to fail up, lock in the last position, or fail down. When the supply

pressure rises above the trip point, the 377 trip valve automatically resets, allowing the system to return to normal

operation. The trip valve can be top‐mounted on a manifold, yoke‐mounted, or bracket‐mounted to match the

application requirements. 377 trip valves are used with all types of piston actuators.

Instruction Manual

D200319X012

377 Trip Valve

August 2012