C1 Controllers and Transmitters

Instruction Manual

September 2009

4

Table 1. Specifications (continued)

Ambient Operating Temperature Limits

J

Standard Construction:

−

40 to 71

_

C (

−

40 to

160

_

F)

J

High Temperature Construction:

−

18 to

104

_

C (0 to 220

_

F)

Anti

−

reset windup (differential pressure relief) and

process pressure gauge options are only

available in the standard construction

If the process temperature is outside the ambient

operating range of the controller, the length of the

capillary tube run from the sensor point to the

controller process input may be adjusted to

protect the controller from the process

temperature

Typical Ambient Temperature Operating

Influence

Proportional Control only:

Output pressure changes

$

3.0% of sensing

element range for each 28

_

C (50

_

F) change in

temperature between

−

40 and 71

_

C (

−

40 and

160

_

F) for a controller set at 100% proportional

band

Proportional

−

Plus

−

Reset Control:

Output pressure changes

$

2.0% of sensing

element range for each 28

_

C (50

_

F) change in

temperature between

−

40 and 71

_

C (

−

40 and

160

_

F) for a controller set at 100% proportional

band

Transmitters only:

Output pressure changes

$

3.0% of sensing

element range for each 28

_

C (50

_

F) change in

temperature between

−

40 and 71

_

C (

−

40 and

160

_

F) for a transmitter set at 100% span

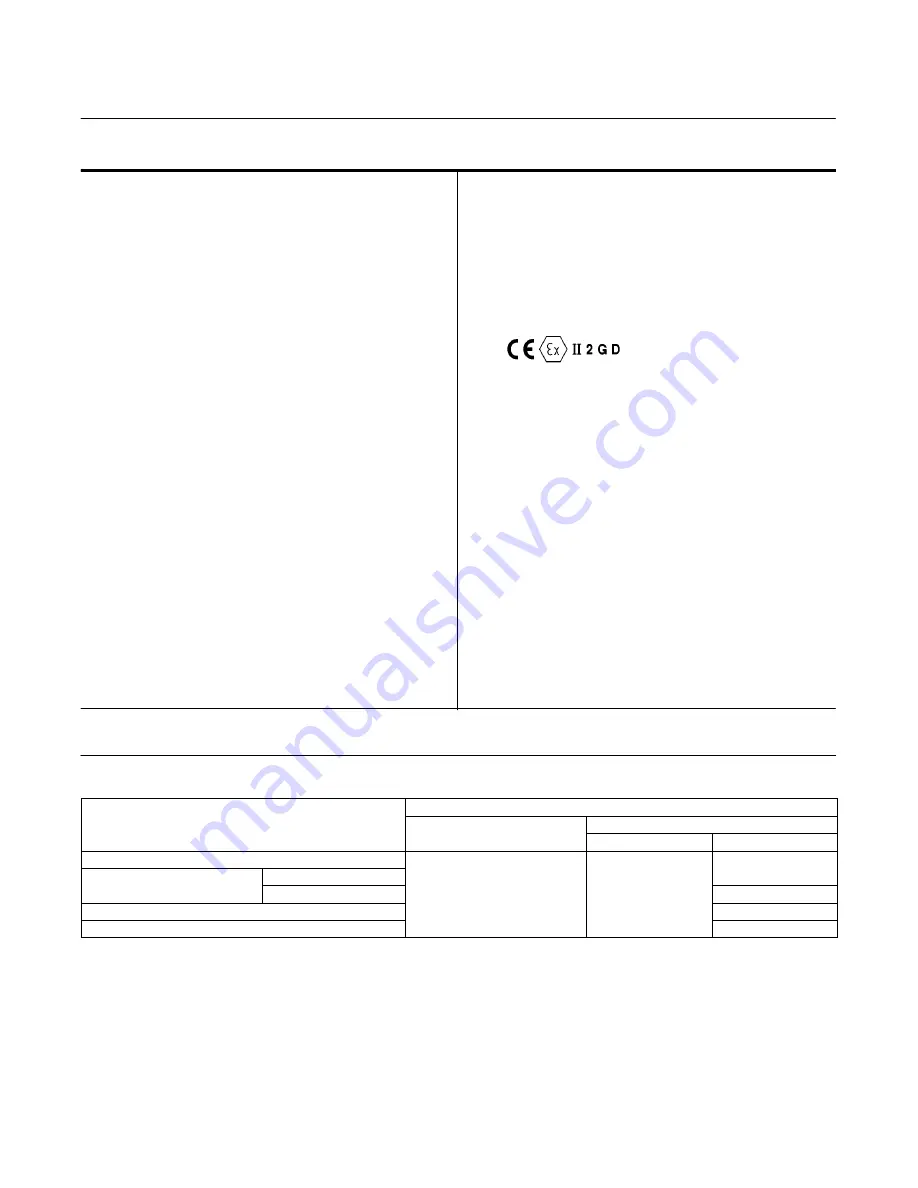

Hazardous Area Classification

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

Refer to figure 25 for location of ATEX marking

Approximate Weight

8.2 kg (18 pounds)

Options

Case pressure tested to 0.14 bar (2 psig)

Declaration of SEP

Fisher Controls International LLC declares this

product to be in compliance with Article 3

paragraph 3 of the Pressure Equipment Directive

(PED) 97 / 23 / EC. It was designed and

manufactured in accordance with Sound

Engineering Practice (SEP) and cannot bear the

CE marking related to PED compliance.

However, the product may bear the CE marking to

indicate compliance with other applicable

European Community Directives.

1. The pressure/temperature limits in this document and any applicable standard or code limitation should not be exceeded.

2. Normal m

3

/hr: normal cubic meters per hour (m

3

/hr, 0

_

C and 1.01325 bar, absolute). Scfh: standard cubic feet per hour (ft

3

/hr, 60

_

F and 14.7 psig).

3. To convert from air flow rate to natural gas flow rate multiply by 1.29.

4. An adjustable differential gap (differential gap controllers) is equivalent to an adjustable deadband.

Table 2. Available Configurations

TYPE NUMBER

DESCRIPTION

Bourdon Tube Sensing

Element (Gauge Pressure Only)

Bellows Sensing Element

Gauge Pressure

Differential Pressure

Proportional

−

only controller

C1P

C1B

C1D

Proportional

−

plus

−

reset controller

Without anti

−

reset windup

With anti

−

reset windup

−

−

−

Differential gap controller

−

−

−

Transmitter

C1D