C1 Controllers and Transmitters

Instruction Manual

September 2009

8

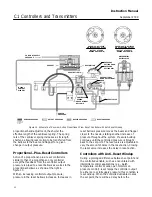

If operating the controller or transmitter from a high

pressure source [up to 138 bar (2000 psig)], use a

high pressure regulator system, such as the Fisher

1367 High Pressure Instrument Supply System. For

1367 system installation, adjustment, and

maintenance information, refer to the 1367

High

−

Pressure Instrument Supply System with

Overpressure Protection instruction manual,

D100343X012.

Process Pressure

WARNING

To avoid personal injury or property

damage resulting from the sudden

release of pressure when using

corrosive media, make sure the tubing

and instrument components that

contact the corrosive medium are of

suitable noncorrosive material.

Also refer to the Installation Warning

at the beginning of this section.

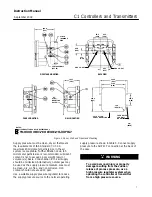

The pressure connections to the controller depend

upon the type of pressure sensing, gauge or

differential. Gauge pressure controllers use either a

Bourdon tube or bellows as the sensing element, as

indicated in table 2. Differential pressure controllers

use two bellows to sense differential pressure.

For gauge pressure instruments: The control

pressure block (key 10 in figure 21) has two

connections. Process pressure can be connected

either to the CONTROL connection on the back of

the case, or to the connection on the left side of the

case, shown in figure 2, depending on the

instrument application. Plug the unused connection.

For differential pressure instruments: Connect

the low pressure line to the CONTROL connection

on the side of the case and the high pressure line to

the CONTROL connection on the back of the case

as shown in figure 2.

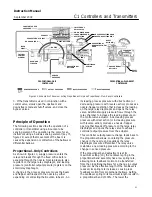

When installing process piping, follow accepted

practices to ensure accurate transmission of the

process pressure to the controller or transmitter.

Install shutoff valves, vents, drains, or seal systems

as needed in the process pressure lines. If the

instrument is located such that the adjacent process

pressure lines will be approximately horizontal, the

lines should slope downward to the instrument for

liquid

−

filled lines and upward to instruments for

gas

−

filled lines. This will minimize the possibility of

Table 6. Common Signal Pressure Conversions

Mps

kg/cm

2

bar

kPa

Psi

0.02

0.03

0.04

0.05

0.06

0.2

0.3

0.4

0.5

0.6

0.2

0.3

0.4

0.5

0.6

20

35

40

50

60

3

5

6

7

9

0.07

0.08

0.09

0.10

0.12

0.8

0.8

1.0

1.0

1.3

0.8

0.8

1.0

1.0

1.2

75

80

95

100

125

11

12

14

15

18

0.14

0.15

0.17

0.18

0.20

1.4

1.5

1.8

1.9

2.0

1.4

1.5

1.7

1.9

2.0

140

150

170

185

200

20

22

25

27

30

0.22

0.23

0.24

0.34

0.55

2.2

2.3

2.5

3.5

5.6

2.2

2.3

2.4

3.4

5.5

220

230

240

345

550

32

33

35

50

80

0.69

1.03

7.0

10.5

6.9

10.3

690

1035

100

150

1. Values as listed in ANSI/S7.4.

2. Values as listed in IEC Standard 382.

3. Values rounded to correspond with kPa values.

air becoming trapped in the sensor with liquid

−

filled

lines or of condensation becoming trapped with

gas

−

filled lines. The recommended slope is 83 mm

per meter (1 inch per foot).

If a controller is being used in conjunction with a

control valve to control pipeline pressure, connect

the process pressure line in a straight section of pipe

approximately 10 pipe diameters from the valve but

away from bends, elbows, and areas of abnormal

fluid velocities. For pressure

−

reducing service, the

process line must be connected downstream of the

valve. For pressure

−

relief service, the process

pressure line must be connected upstream of the

control valve. Install a needle valve in the process

pressure line to dampen pulsations.

Vent Assembly

WARNING

Personal injury or property damage

could result from fire or explosion of

accumulated gas, or from contact with

hazardous gas, if a flammable or

hazardous gas is used as the supply

pressure medium. Because the

instrument case and cover assembly

do not form a gas

−

tight seal when the

assembly is enclosed, a remote vent