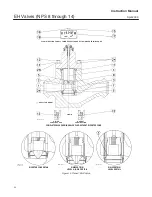

EH Valves (NPS 8 through 14)

Instruction Manual

April 2009

21

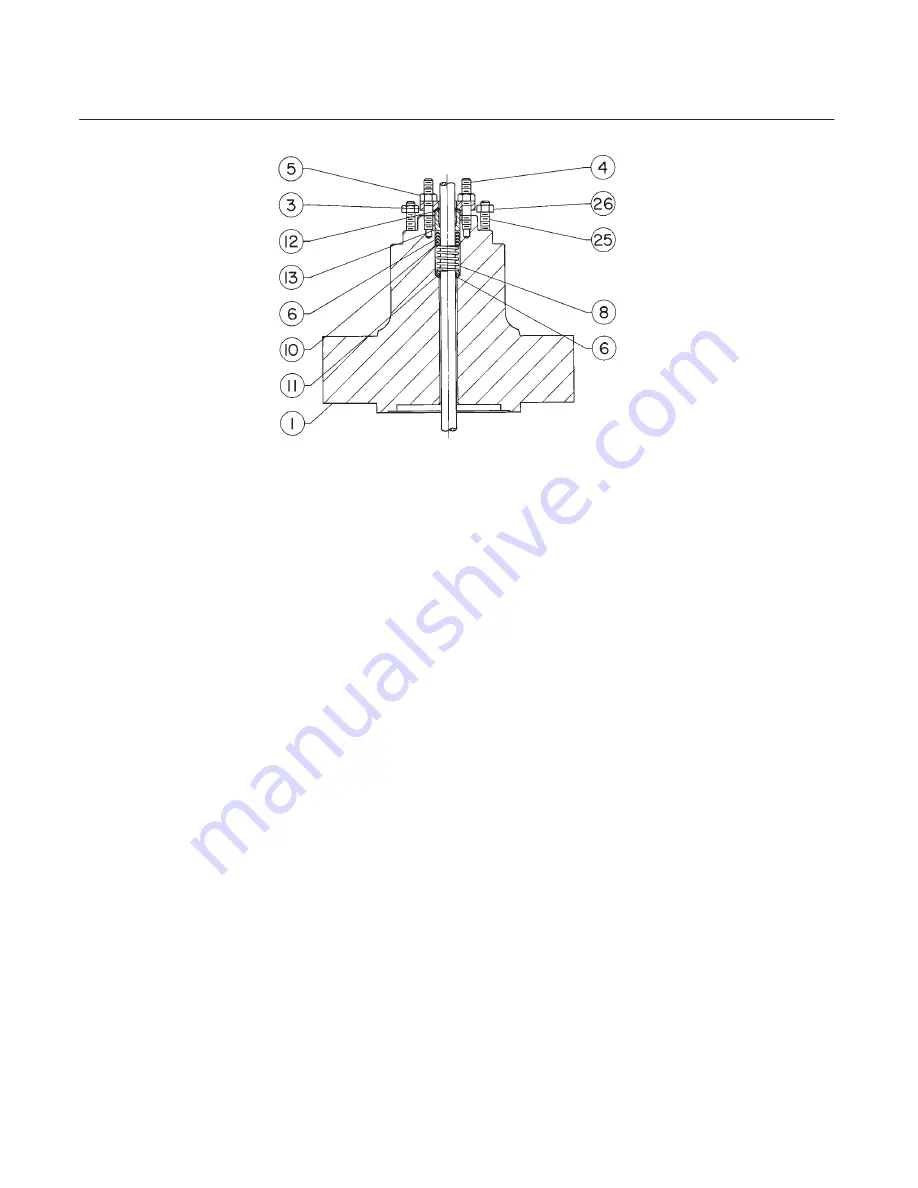

Figure 11. Bonnet Assembly

35A3976-A / IL

Parts List

Note

Part numbers are shown for recommended spares

only. For part numbers not shown, contact your

Emerson Process Management sales office.

Key

Description

Part Number

Bonnet Assembly (figures 4 and 11)

1 Bonnet

If you need a bonnet as a replacement

part, order by valve size and stem

diameter, serial number, and desired

material.

3 Packing

Flange

4

Packing Flange Stud

127 mm (5-inch) yoke boss diameter

(2 req’d)

178 mm (7-inch) yoke boss diameter

(3 req’d)

Key

Description

Part Number

5

Packing Flange Nut

127 mm (5-inch) yoke boss diameter

(2 req’d)

178 mm (7-inch) yoke boss diameter

(3 req’d)

6*

Packing Set

See following table

7*

Packing Ring

See following table

8

Spring or Lantern Ring

See following table

9*

Packing Ring

See following table

10

Washer

See following table

11* Packing Box Ring

See following table

12* Upper Wiper, felt

See following table

13

Packing Follower, 316 stainless

steel

See following table

14

Pipe Plug (not shown)

Steel

316 stainless steel

14

Lubricator, steel (not shown)

14

Lubricator/Isolating Valve (not shown)

25

Actuator Mounting Stud, steel

(8 req’d)

26

Hex Nut, steel (8 req’d)

30* Lower Wiper, PTFE

See following table

31* Male Adapter, PTFE

See following table

32* Female Adapter, PTFE/glass

See following table

*Recommended spare parts