Type ACE95JR

D102774X012

Instruction Manual

Form 5666

January 2016

www.fisherregulators.com

Type ACE95jr Tank Blanketing Valve

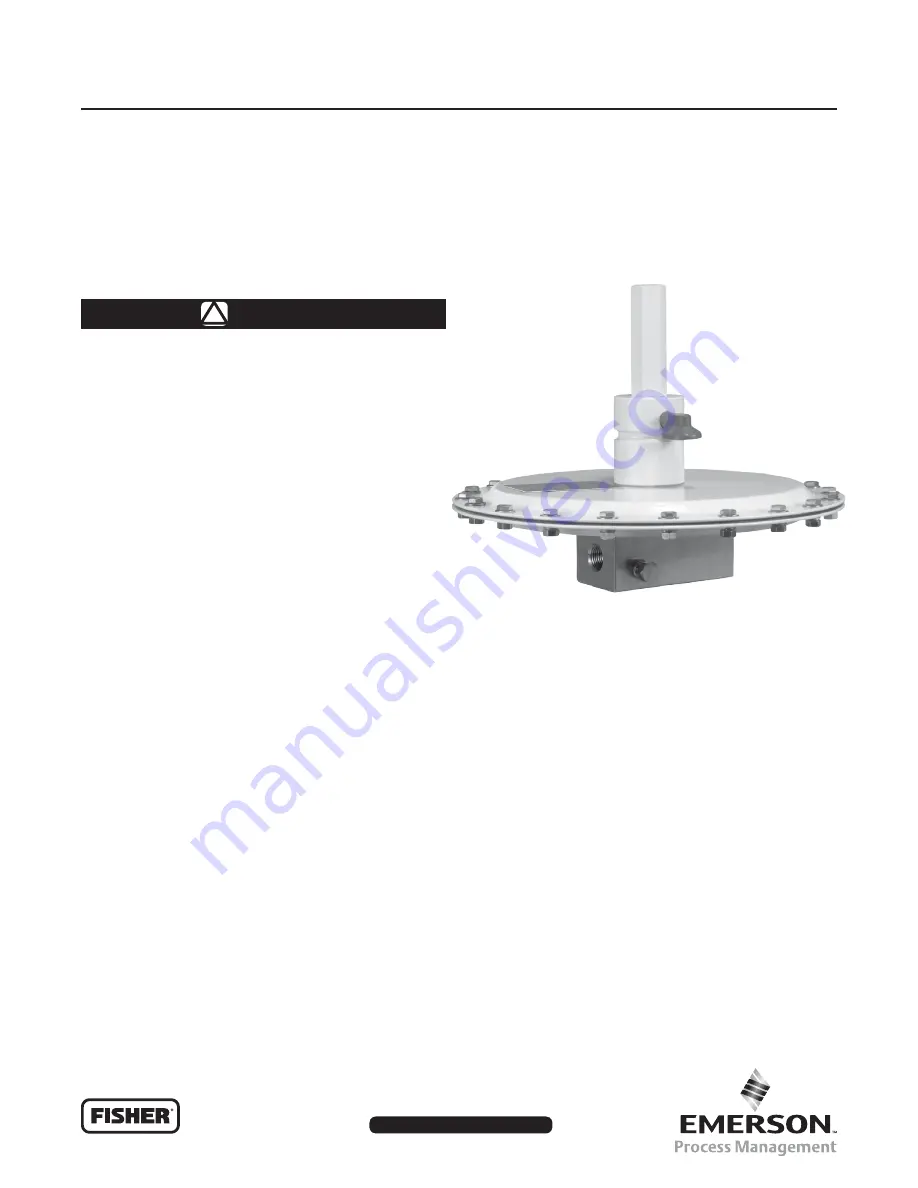

Figure 1.

Type ACE95jr Tank Blanketing Valve

Introduction

!

WArnIng

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

fire and/or chemical contamination

causing property damage and personal

injury or death.

Fisher

®

Tank blanketing valves must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations

and Emerson Process Management

regulator Technologies, Inc.

(Emerson™) instructions.

If the valve vents gas or a leak develops

in the system, service to the unit may be

required. Failure to correct trouble could

result in a hazardous condition.

Installation, operation and maintenance

procedures performed by unqualified

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury. Use qualified

personnel when installing, operating

and maintaining the Type ACE95jr Tank

Blanketing Valve.

Scope of the Manual

This Instruction Manual provides installation, startup

and maintenance procedures for the Type ACE95jr

tank blanketing valve. See Figure 1.

Product Description

The Type ACE95jr tank blanketing valve is an

extension of the Type ACE95 tank blanketing valve

and is intended to handle lesser flows on gas

blanketing systems. The valve prevents a stored

product from vaporizing into the atmosphere, reduces

product combustibility and prevents oxidation or

contamination of the product by reducing its exposure

to air. The Type ACE95jr maintains a slightly positive

pressure and thereby reduces the possibility of tank

wall collapse during pump out operations.

W8157