EU and EW Series Valves

Instruction Manual

August 2010

8

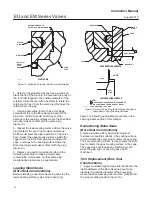

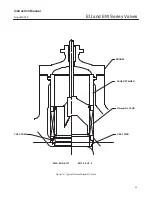

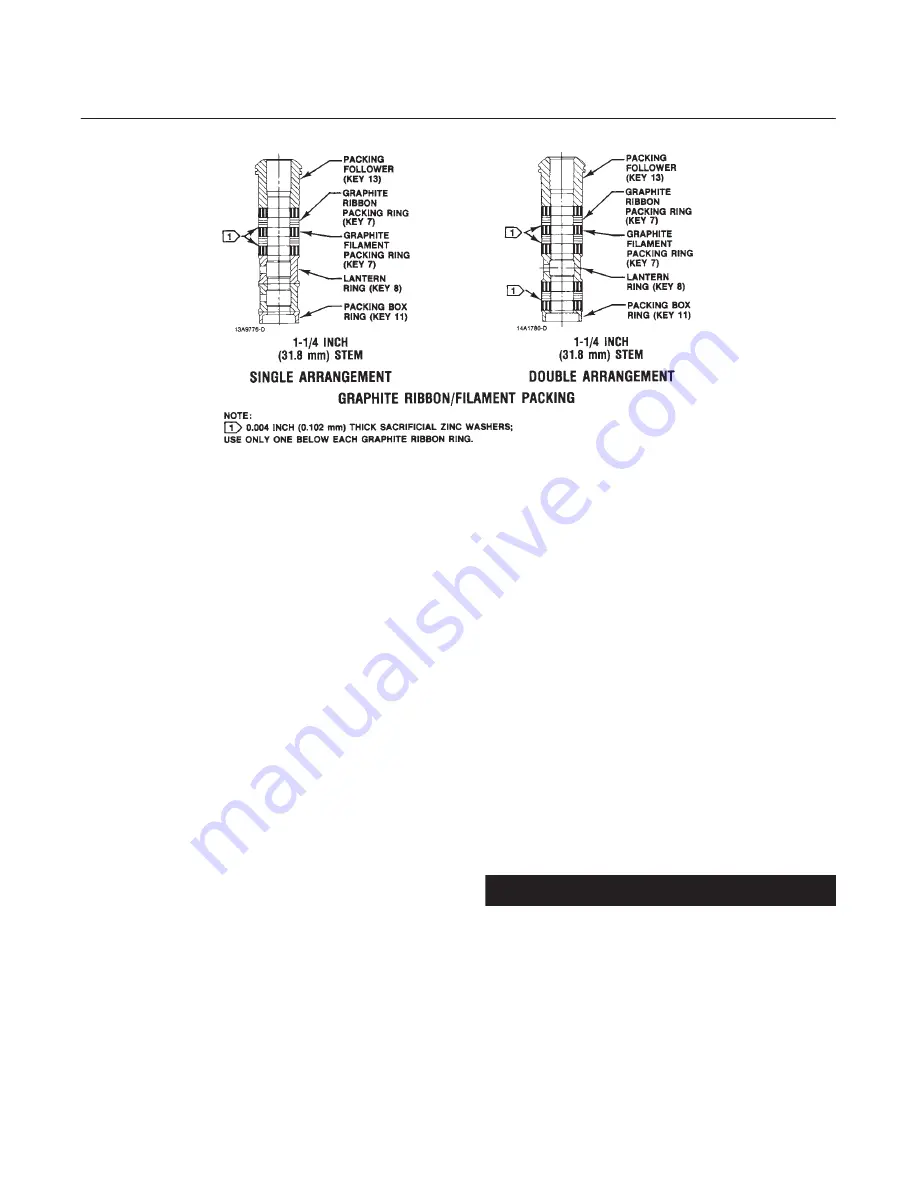

Figure 4. Typical Packing (Continued)

A6060/IL

Packing Maintenance

This procedure does not cover ENVIRO-SEAL or

HIGH-SEAL packing; refer to separate manuals for

instructions on those packing types.

Key numbers are shown in figure 4 unless otherwise

indicated.

For spring-loaded single PTFE V-ring packing, the

spring (key 8) maintains a sealing force on the

packing. If leakage is noted around the packing

follower (key 13), check to be sure the shoulder on

the packing follower is touching the bonnet. If the

shoulder is not touching the bonnet, tighten the

packing flange nuts (key 5, figure 5) until the

shoulder is against the bonnet. If leakage cannot be

stopped in this manner, proceed to the Replacing

Packing section.

If there is undesirable packing leakage with other

than spring-loaded packing, first try to limit the

leakage and establish a stem seal by tightening the

packing flange nuts.

If the packing is relatively new and tight on the stem

and if tightening the packing flange nuts does not

stop the leakage, it is possible that the valve stem is

worn or nicked so that a seal cannot be made. The

surface finish of a new valve stem is critical for

making a good packing seal. If the leakage comes

from the outside diameter of the packing, it is

possible that the leakage is caused by nicks or

scratches around the packing box wall. If performing

any of the following procedures, inspect the valve

stem and packing box wall for nicks and scratches.

Replacing Packing

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve body,

and drain the process media from both sides of the

valve. If using a power actuator, also shut off all

pressure lines to the power actuator, release all

pressure from the actuator, and use lock-out

procedures to prevent injury while you work on the

equipment.

2. Remove any leak-off piping from the bonnet.

Disconnect the stem connector, and then remove

the actuator from the valve by unscrewing the hex

nuts (key 26, figure 5).

3. Loosen the packing flange nuts (key 5, figure 5)

so that the packing is not tight on the valve stem.

Remove any travel indicator parts and stem locknuts

from the valve stem threads.

CAUTION

Avoid damage to the seating surfaces

caused by the valve plug and stem

assembly dropping from the bonnet

after being lifted part way out.

When lifting the bonnet (key 1, figure

5), either be sure that the valve plug

and stem assembly remains in the

valve and on the seat or, temporarily

install a valve stem locknut on the