Summary of Contents for FS2MIF-141AE2

Page 8: ...5 Wiring diagram FS2MIF 141AE2 FS2MIF 181AE2 FS3MIF 211AE2 FS3MIF 271AE2 8 ...

Page 9: ...FS4MIF 281AE2 FS4MIF 361AE2 9 ...

Page 10: ...FS5MIF 421AE0 10 ...

Page 33: ...9 3 1 2 Indoor outdoor units communication error ...

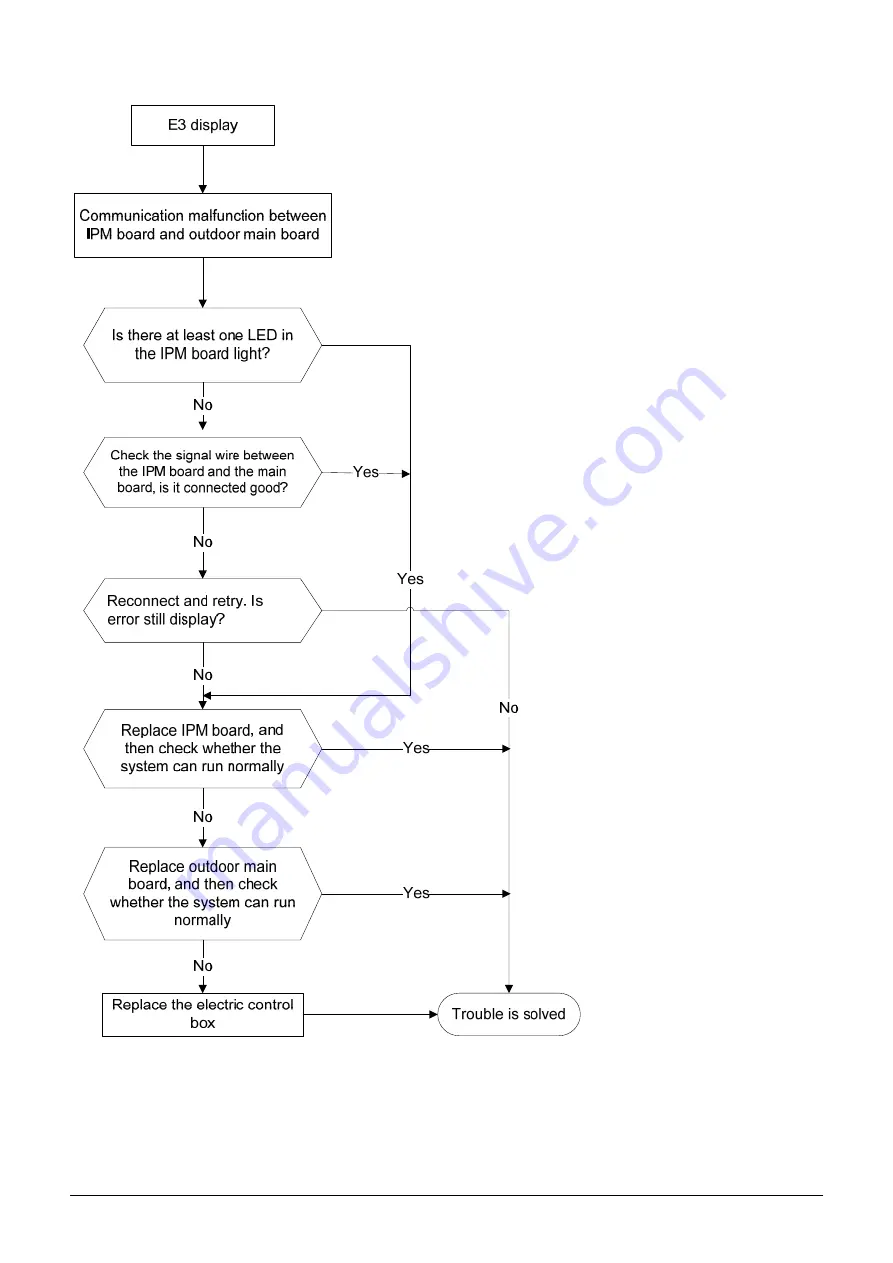

Page 41: ...9 3 3 2 Communication malfunction between IPM board and outdoor main board ODU E3 ...

Page 44: ...9 3 3 5 High pressure protection ODU P1 For FS4MIF 281AE2 FS4MIF 361AE2 FS5MIF 421AE0 ...

Page 46: ...9 3 3 7 Current protection of compressor ODU P3 ...