Instruction Manual

D104296X012

LCP200 Local Control Panel

August 2018

13

LCP200

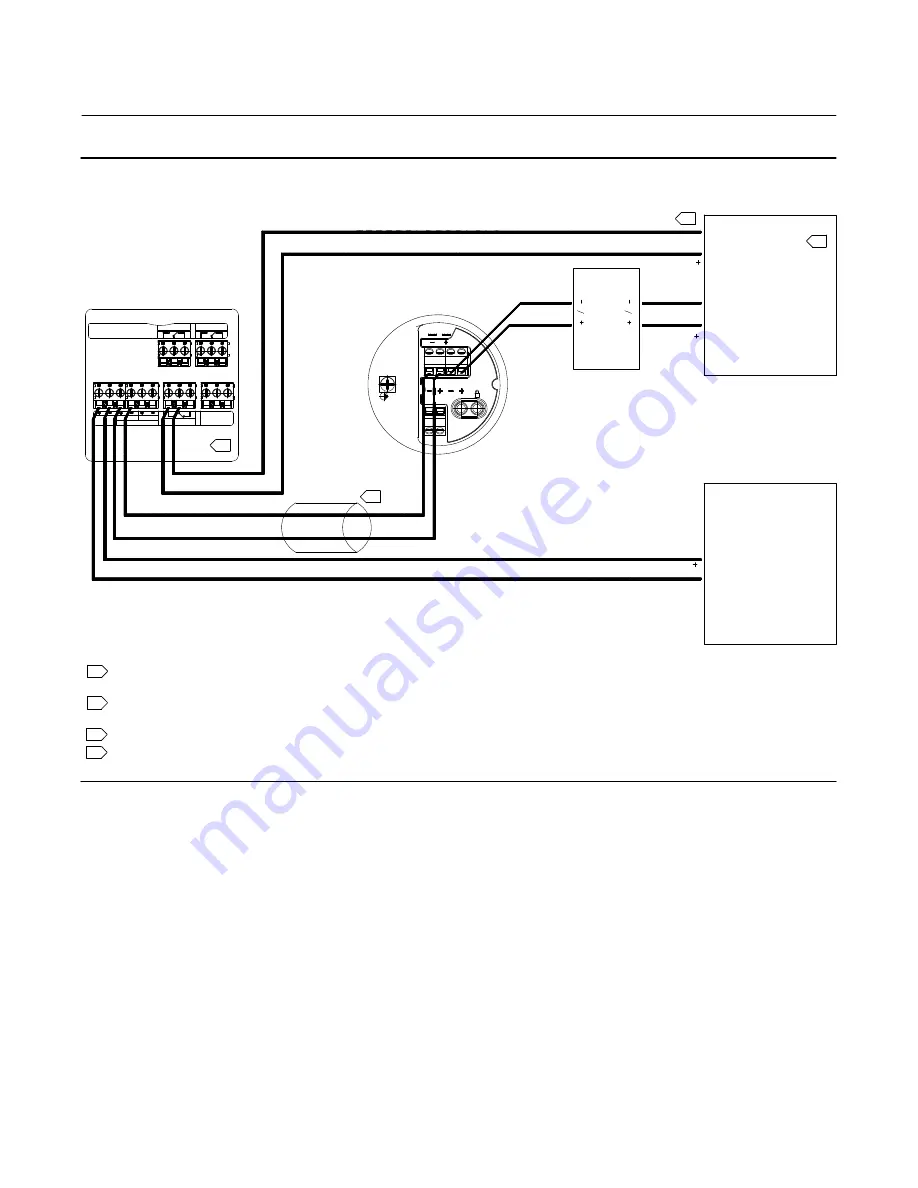

Figure 9. Wiring Diagram 4, 24 VDC External Power Configuration, Multi-Drop

GG22618 SHEET 5

NOTES:

1 OPTIONAL CABLING TO RESET, TRIP AND TEST CONTACTS. SHOWN ABOVE IS CABLING TO

1

RESET CONTACT.

2 CONNECT EITHER NO-C OR NC-C TERMINALS OF RESET, TRIP AND TEST CONTACTS. SHOWN

1

ABOVE IS RESET NO-C TERMINALS.

3 USE METAL CONDUIT FOR CABLING BETWEEN DVC6200 SIS AND LCP200 AS EMI SHIELD.

4 THE DIGITAL INPUT DOES NOT NEED TO BE CONNECTED FOR THE LCP200 TO OPERATE.

LOGIC SOLVER

(USER SUPPLIED)

3

1

DVC6200 SIS

TERMINAL BOX

DIGITAL IN

24 VDC

SOURCE

2

LC340 LINE

CONDITIONER

OPUTPUT

24 VDC

(USER SUPPLIED)

TALK

CAL

AUX LOOP

DVC6200 SIS

TEST

TRIP

NOT

AVAILABLE

RESET

POWER

24V

AUX LOOP

OUT

4

FLD

SYS