Lit. No. 94196/94197/94198, Rev. 05

16

November 1, 2010

OPERATING THE SPREADER – CAB CONTROL

DIAGNOSTIC INDICATOR LIGHT AND

AUDIO BEEP

The diagnostic indicator light located to the right of

the START/BLAST button remains dark unless a

problem with the motor or wiring is detected. The light

will

fl

ash in coordination with an audio beep a number

of

fl

ashes/beeps in a row, pause, then repeat. Count

the

fl

ashes/beeps to determine the nature of the

malfunction and refer to diagnostic chart below.

NOTE: Always close the lids on the hopper to

prevent moisture buildup. Do not let spreader sit

idle with material in the hopper for an extended

period of time. This can cause material to

compact, reduce or stop the

fl

ow of material and

cause permanent hopper body deformation.

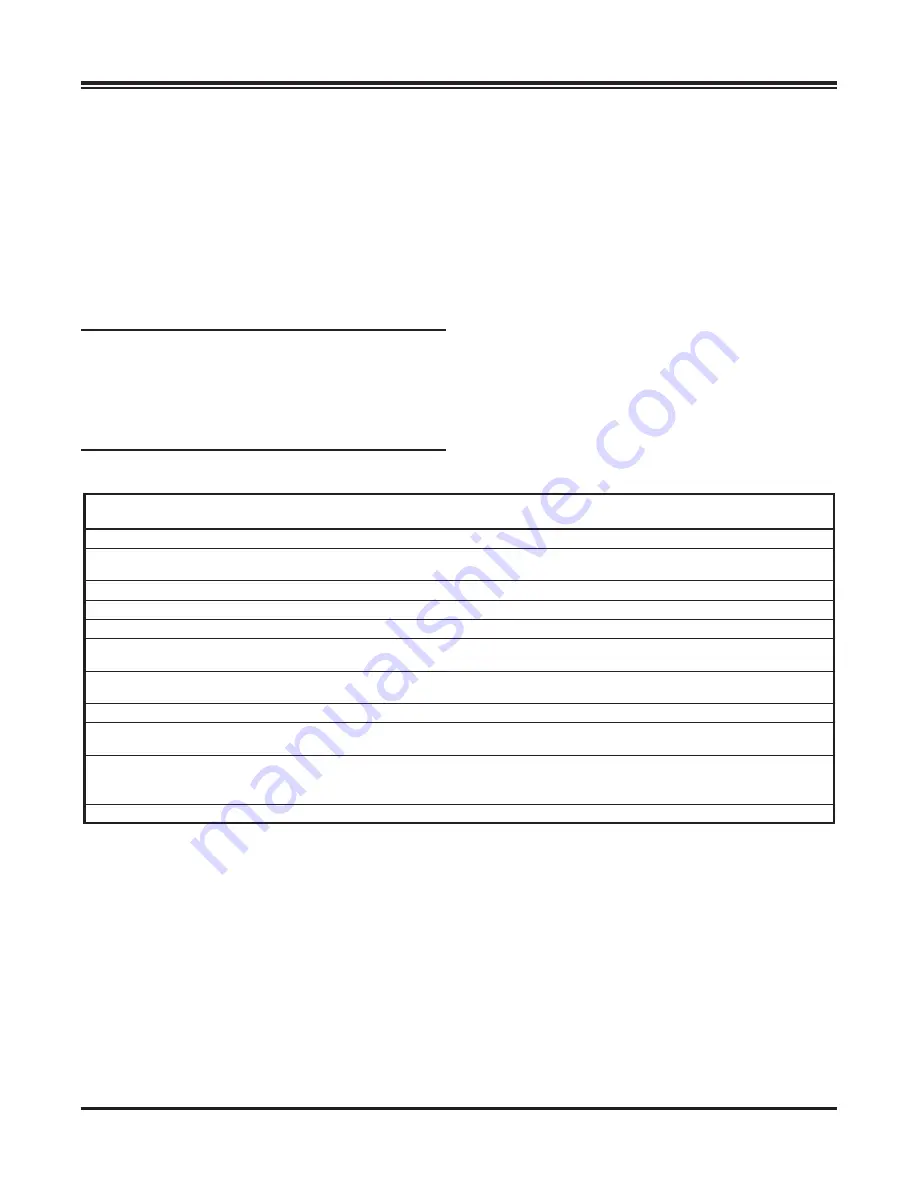

# of

Flashes/Beeps

Problem

Possible Cause

0

No Error

–

1

No Communication

Loss of communication between spreader module and cab control. Vehicle

cable assembly is disconnected or faulty.

2

Empty Hopper

Spreader is empty or material has bridge in the hopper.

3

Conveyor Over Current Over 70 amps for up to 3 seconds. Conveyor Chain is stalled.

4

No Power

Battery fuse is blown or vehicle cable assembly is disconnected or faulty.

5,8

Over Temp

Motor is OFF due to spreader module overheating from high-current draw

over a long period of time.

6

Battery Saver

Reduced spreader performance due to vehicle voltage drop. Spreader will

function at reduced output until vehicle voltage increases.

7

Spinner Over Current Over 32 amps for up to 3 seconds. Spinner is stalled.

9

Sander Reset

Module came out of reset. Momentary loss of power. Restart unit, check

power wiring.

10

Cool Down

If the unit gets more than 5 faults with each fault starting within 60 seconds

from the last, it will not start for 60 seconds from the last fault to allow the unit

to cool.

11

Low Battery

Low battery voltage or poor electrical connection of vehicle cable assembly.