Lit. No. 43573/43583/43593, Rev. 01

10

August 15, 2013

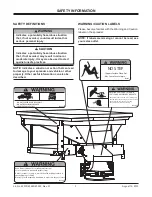

MOUNTING THE SPREADER

8. Once the spreader is positioned front to back,

center it left to right. Looking at the inside front

and rear corner of the lower frame area, you will

notice four holes in the bottom of the frame. Using

a paint pen or similar marking device, mark hole

locations.

9. Drill holes at the marked locations.

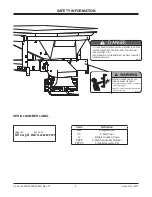

10. Install and tighten all four cap screws.

11. Install the four ratchet straps as shown below.

NOTE: It is important for safety that this strapping

method be used as the standard mounting

procedure.

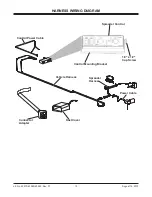

12. Connect the spreader power cord to vehicle

main power plug mounted at the rear of the

vehicle (refer to installation instructions for wiring

instructions).

Cross left upper to

right lower

Strap from rear

of vehicle to front

corner (both sides)

Cross right upper to

left lower

Tarp Kit

Ratchet Strap

CAUTION

Before drilling holes, check to be sure that no

vehicle wiring or other components could be

damaged.

Summary of Contents for POLY-CASTER

Page 2: ......