18

During testing, the screens will display icons showing the status, options available

and prompts for testing:

No.

000001

The sequential test number assigned to the next test to be run. In

Routine

Mode, the first digit will be

0

. In

STAT

Mode, the first digit

will be

1

. In

QC

Mode, the first digit will be

2

.

51100

(10SG)

Indicates the proper strip to be tested has 10 test pads. Standard

strips available are 4, 8, or 10 test parameters, refer to Appendix 2.

Select the strip configuration using the

MENU

function from the Initial

Screen. The strip type must match the strip being used or result will

not be displayed.

Mode

Indicates the current mode setting. Available modes are

Routine,

STAT

and

QC

. Press

ENTER

from this screen to change the mode.

Continue to press

ENTER

to cycle through each mode. The mode

may be changed when this prompt appears.

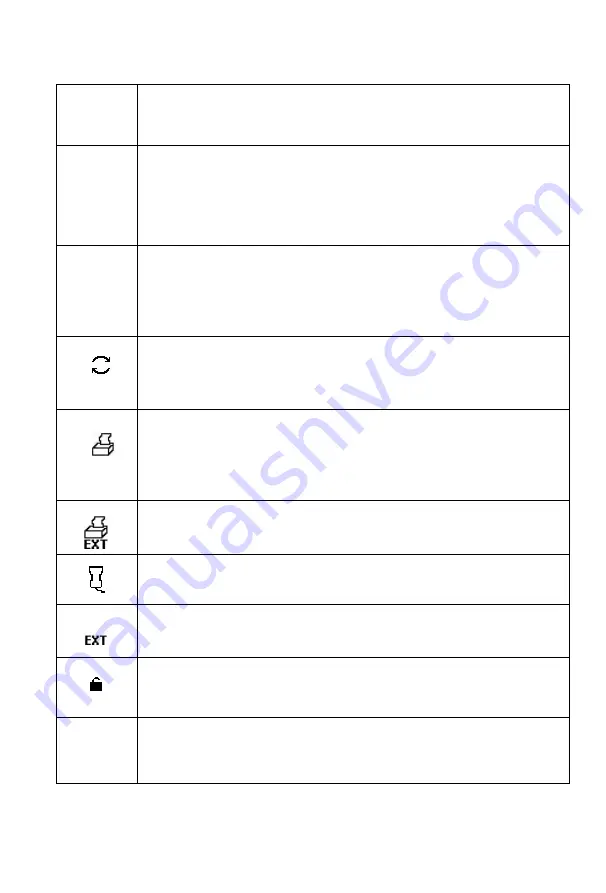

When visible, Continuous Test is set to test up to 120 tests per hour.

If not, Single Test is set to test one strip at a time up to 60 tests per

hour.

When visible, the printer is set to

Auto-print

. Test data is sent to the

internal printer and data ports after each test. Results are displayed

on the screen. If this icon is not visible, press

to send results to

the printer and data port.

When visible,

Auto-Print

is

On

. Test data is sent to the external

printer and data ports after each test.

When visible, indicates the Barcode reader is enabled.

If only

EXT

is visible,

Auto-Print

is

Off.

Press

to send test data

to the printer and data port.

Strip Lockout is available. The analyzer will only test strips with correct

barcodes. There will be no symbol if Strip Lockout is not an included

function.

QC

When visible, indicates QC Lockout is

On

. When the scheduled test

time arrives, this symbol will flash. A beep will be heard to prompt

that a QC test is required before performing additional tests.