8

MAINTENANCE & CARE

General cleaning will help prolong the life and performance of your treadmill. Keep the unit clean and

maintained by dusting the components on a regular basis. Clean both sides of the

Running Belt (No.

17)

to prevent dust from accumulating underneath the

Running Belt (No. 17)

. Keep your running shoes

clean so that dirt from your shoes does not wear out the

Running Board (No. 16)

and

Running Belt

(No. 17)

. Clean the surface of the

Running Belt (No. 17)

with a clean damp cloth.

To better maintain the treadmill and prolong its life it is suggested that the machine be powered off for

10 minutes every 2 hours and fully powered off whenever not in use.

A loose

Running Belt (No. 17)

will result in the runner sliding off when running, while too tight of a

Running Belt (No. 17)

will negatively affect the motor’s performance and also create more friction

between the roller and

Running Belt (No. 17)

. The most suitable tightness for the

Running Belt (No.

17)

is pulled out

50-75mm

from the

Running Board (No. 16)

.

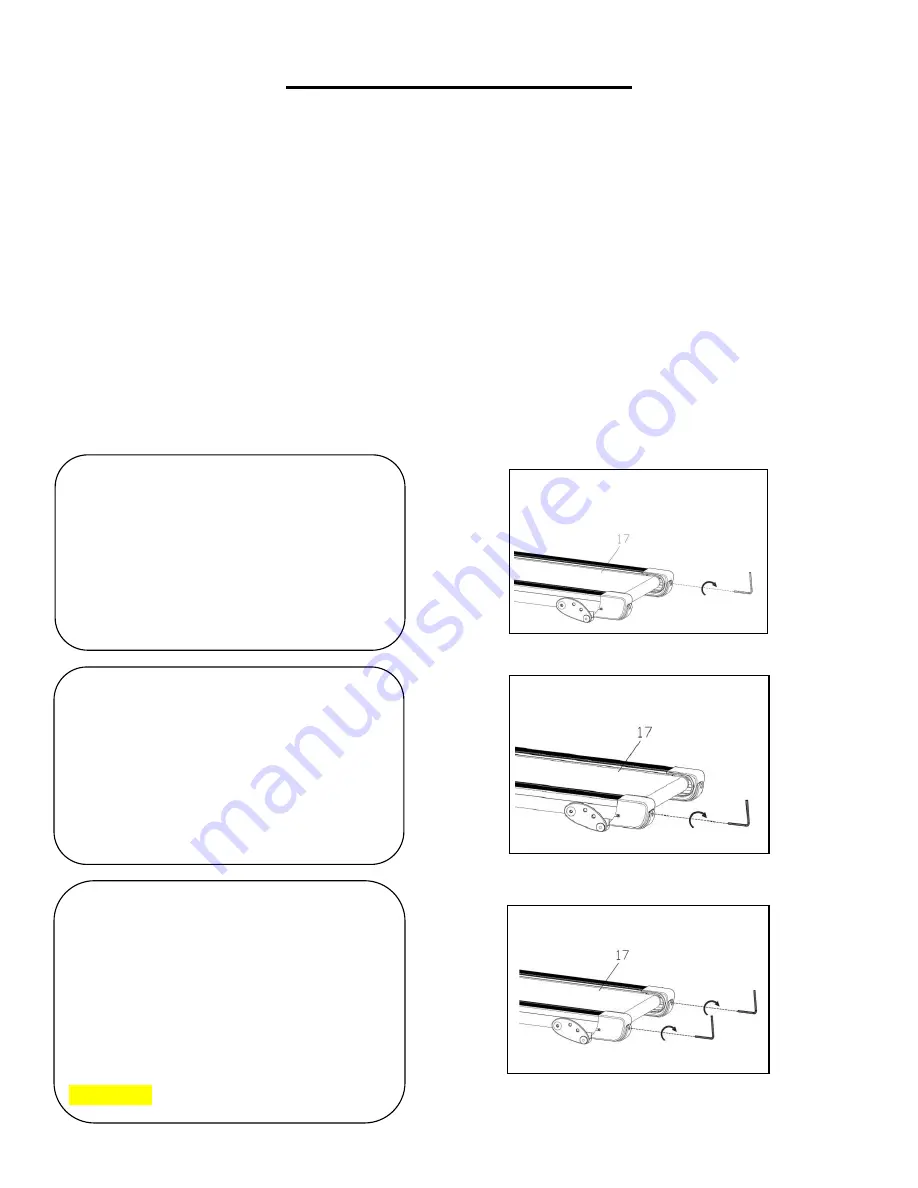

CENTERING THE RUNNING BELT:

Place the treadmill on level ground and set it at 3-5mph to check if the

Running Belt (No. 17)

drifts.

1. If the

Running Belt (No. 17)

moves

to the right, turn the adjusting bolt on

the right side

¼

turn

clockwise

, then

turn the left adjustment bolt ¼ turn

counter-clockwise

. If the

Running

Belt (No. 17)

does not move, keep

adjusting ¼ turn at a time until it

centers. Refer to Fig. A.

2. If the

Running Belt (No. 17)

moves

to the left, turn the adjusting bolts on

the left side

¼

of a turn

clockwise

,

then turn the right adjustment bolt ¼

turn

counter-clockwise

.

If

the

Running Belt (No. 17)

does not move,

keep adjusting ¼ turn at a time until it

centers. Refer to Fig. B.

3. Over time the

Running Belt (No.17)

will loosen. To tighten the belt turn the

Left

&

Right

side adjustment bolts one

full turn

clockwise

, check the tension of

the

Running Belt (No. 17)

. Continue

this process until

Running Belt (No.

17)

is at the correct tension. Make sure

to adjust both sides equally to ensure

correct

Running Belt (No. 17)

alignment. Refer to Fig. C.

Fig.A

Fig. B

Fig. C