20

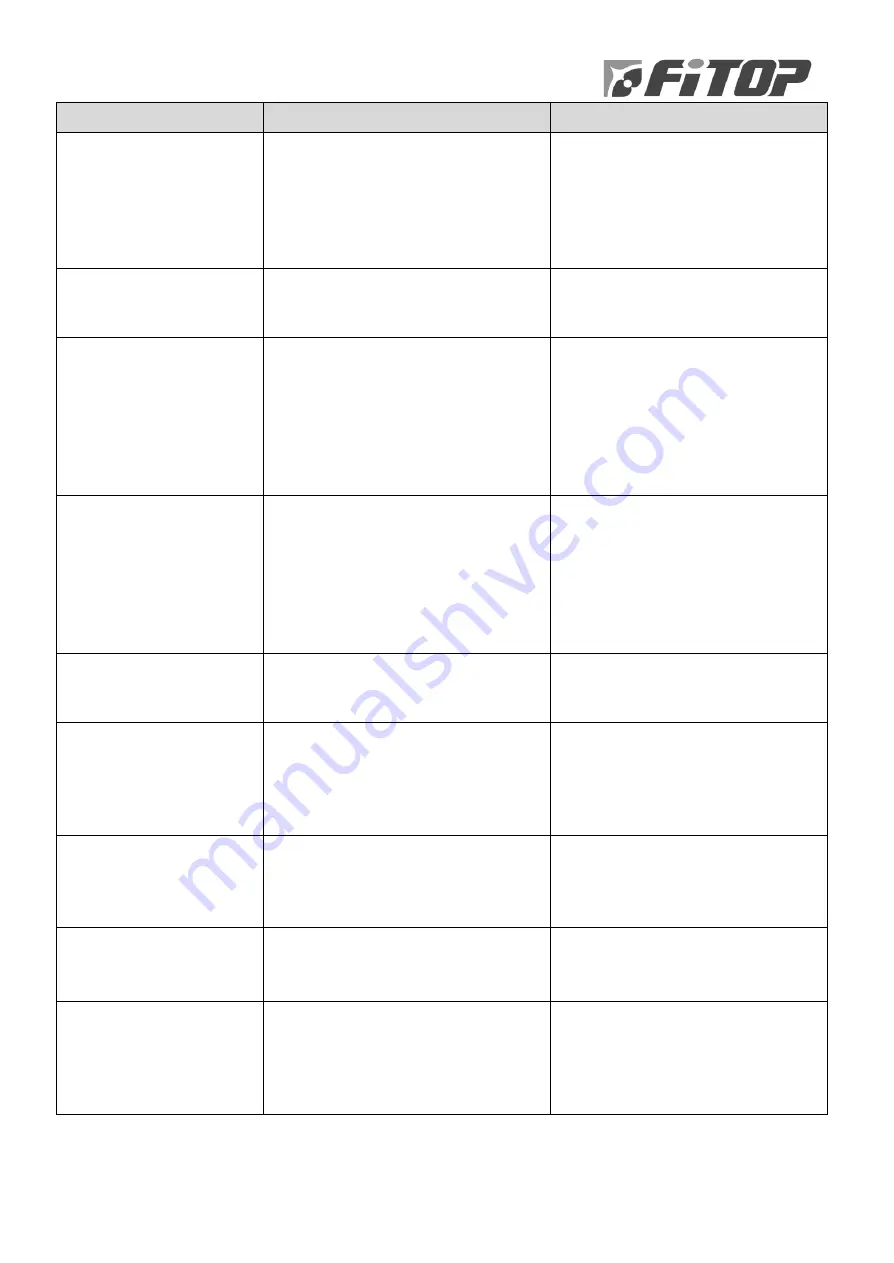

Trouble

Possible causes

Trouble-shooting

13. Trolley cannot move

towards WEST

(1)

Check up WEST limit switch

(2)

The “WEST” current of hoisting has

broken

(3)

Push button “WEST” malfunctions

(4)

Contactor of WEST malfunctions

(1)

Replace with a new WEST limit-

switch

(2)

Check the break point of current

(3)

Replace with a new push-button

(4)

Replace with a new “WEST”

contactor

14. Trolley cannot move

towards EAST and WEST

(Trolley motor stopped)

(1)

The brake of trolley motor is not

turned ON

(2)

The trolley motor has burnt out

Contact the supplier or the regional

distributor.

15. End-carriage cannot

move towards SOUTH

(1)

Check up the SOUTH limit switch

(2)

The “SOUTH” current has broken

(3)

Push-button “SOUTH”

malfunctions

(4)

Contactor of SOUTH malfunctions

(1)

Replace with a new SOUTH limit-

switch

(2)

Check up the circuit point that

failed

(3)

Replace with a new push-button

(4)

Replace with a new SOUTH

contactor

16. End-carriage cannot

move towards NORTH

(1)

Check up NORTH limit switch

(2)

The “NORTH” current has broken

(3)

Push-button “NORTH”

malfunctions

(4)

Contactor of NORTH malfunctions

(1)

Replace with a new NORTH limit-

switch

(2)

Check up the circuit point that

failed

(3)

Replace with a new push-button

(4)

Replace with a new NORTH

contactor

17. End-carriage moves

unevenly

(1)

One of motors' brake is not turned

ON or failure to turned on

(2)

One of the motors has burnt out

Contact the supplier or the regional

distributor

18. End-carriage starts and

stops unevenly

(1)

The gaps of motor on the both

sides were not adjusted well

(2)

One of motors’ brakes is not

turned ON

(3)

One of motors has burnt out

Contact the supplier or the regional

distributor

19. The main power failed

(No fuse breaker)

(1)

Three-phase power has two-phase

short-circuit

(2)

Any phase and ground has short-

circuit (electric leakage)

(1)

Check the circuit of power

(2)

Check the reason of electric

leakage

20. Push button does not

work

(1)

Battery has no power

(2)

The fuse of receiver has burnt

(1)

If the RED light is ON, please

replace with a new battery

(2)

Replace the fuse

21. Hoist moves without

operator

(1)

The FREQUENCY of the remote

control is SIMILAR to other remote

controls

(2)

Any phase of control cable with

common line has short-circuit

(1)

Change the frequency of remote

control

(2)

Check it and solve it

Summary of Contents for M Series

Page 1: ...M series OPERATIONS MANUAL ...

Page 24: ...FiTOP 20160620 ...