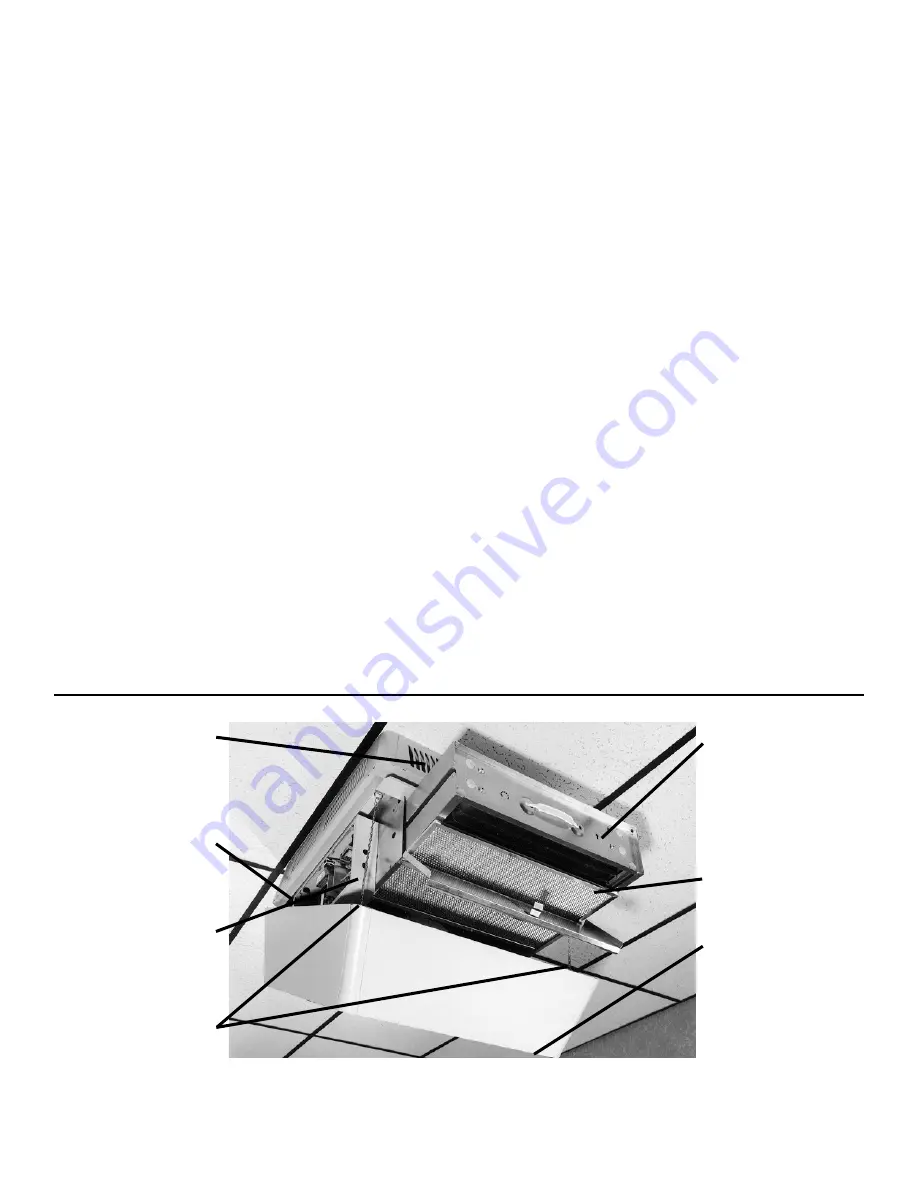

MAJOR COMPONENTS

Description

The Electronic Air Cleaner is approximately 29½ x 27 x

14½ inches (75 x 68.6 x 37 cm). The unit is designed

to be mounted to the ceiling. The steel cover and

intake grill are hinged to allow easy access to the

Collecting Cells and Power Box. The unit is rated up to

1300 CFM (2210 m

3

/hr).

Cabinet

The cabinet is constructed of 20 gauge steel. The

external parts have a tough powder-coated, scratch-

resistant finish. The internal parts are galvanized steel.

Access to the Collecting Cells, Power Box and

Prefilters is made by lifting the cover, sliding towards

the front and lowering.

The cover is interlocked to cut power to the unit when

opened.

Prefilters

The washable Prefilters measuring 12½ x 20 inches

(31.75 x 50.8 cm) are constructed of multi-layers of

aluminum mesh for maximum filtration of large

particles.

Collecting Cells

The dual voltage Collecting Cells are constructed of

heavy gauge aluminum to resist rust and damage. The

first stage, the ionizing section, is charged at

approximately 7500 VDC. The collecting plates are

alternately grounded and charged at 5000 VDC. The

arrow on the Cell indicates the direction of air flow

which must point up towards the fan motor.

Motor & Fan Blade

The motor is 1/12 HP, 1050 RPM, 3 speed, controlled

by a 3-position slide switch. The motor is thermally

protected. The fan blade is aluminum, 18 inches (45.7

cm) with a 16˚ pitch.

INSTALLATION

1. Read instructions carefully. Failure to do so may

result in product damage or injury.

2. Make sure the sizing is correct for your application.

3. Installation should be done by a knowledgeable

technician.

4. After installation, check out operation as provided

in these instructions.

Mounting

1. Remove the unit from the box with packing still on

the unit and lay it on its back, grill side up.

2. Release the cover by sliding towards the front of

the unit and lifting up.

3. Remove the "S" hook from each chain, tilt cover

up, and release from back.

4. Holes are provided in the cabinet to accommodate

5/16 inch (8 mm) threaded rod. Threaded rod can

be attached to angle iron, laid across the joists,

and drilling holes through these supports. Pass

threaded rod up through the supports and secure

with two nuts and washers. This will allow

adjustment of the unit so that it is flush with the

underside of the ceiling.

Leave enough room around the Air Cleaner for

removal of Collecting Cells and Prefilters.

5. Replace cover and chain.

Blower and Motor are

hidden behind 4 directional

discharge air grills.

Rear Hinges permit smooth

release of cover for easy

installation.

3-Speed Fan Control allows

adjustment of air flow to

activity level in room.

Hinged Cover provides

convenient access to Grill,

Prefilters and Collecting

Cells. Safety interlock cuts

power when cover is

opened.

Heavy duty Collecting Cells

(2) capture airborne

pollutants and simply wash

clean.

Washable, aluminum mesh

Prefilters (2) catch lint and

large particles before they

enter collecting cells.

Removable Intake Grill for

easy cleaning.