P/N

DESCRIPTION

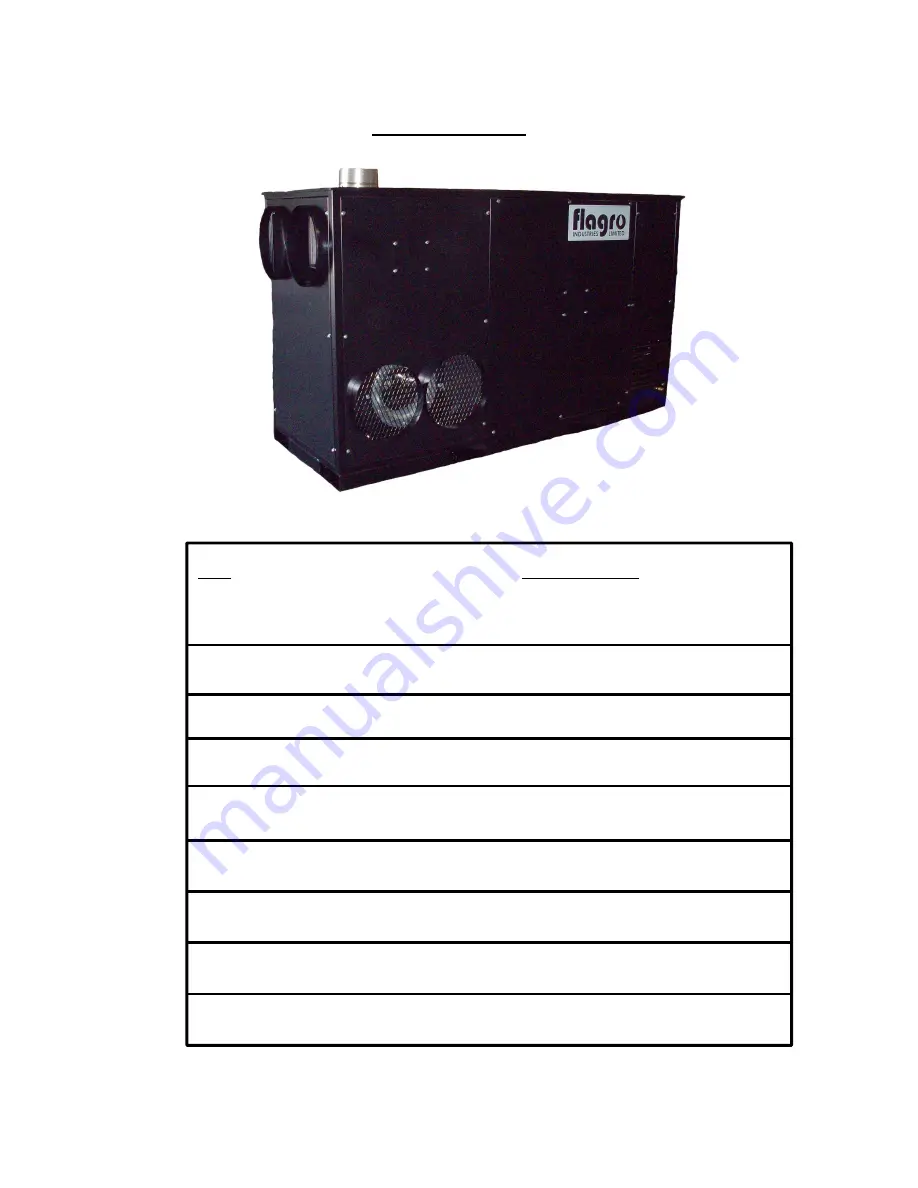

FV750-840

LID

FV750-824

RIGHT SIDE CENTRE PANEL

FV750-823

LEFT SIDE CENTRE PANEL

FV750-828

RIGHT SIDE FRONT PANEL

FV750-827

LEFT SIDE FRONT PANEL -

INLET

FV750-835

LEFT SIDE REAR PANEL

FV750-834

RIGHT SIDE REAR PANEL

FV750-837

REAR ACCESS DOOR

FV750-829

FRONT OUTLET PANEL

BODY PANELS

Summary of Contents for FVN-750

Page 14: ... 14 ...

Page 15: ... 15 Please note FVN P 750 is a single stage burner only ...

Page 25: ......