Heat recovery unit RDKS - Technical manual

25

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

Wrongly adjusted air flows may result in increased

energy consumption and damage to the building.

INTRODUCTION

Adjustment of air flow and temperature may only be carried out by an

installation engineer or service personnel. During adjustment, use the

ISYteq Touch 3.5 control panel (accessory).

AIRFLOW ADJUSTMENT

The speed of the fans is adjusted independently of each other.

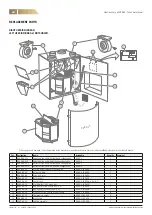

The picture shows an RDKS-1 unit.

AIRFLOW CALCULATION

The unit is equipped with four measurement points as per figure 16

above. Measuring the pressure difference,

D

p

m

in Pa over the impeller

gives the total supply air and extract air flows. The air flow q in l/s is

determined using the following formula:

q = 0.73 x

D

p

m

where

D

p

m

= measured pressure in point T – measured pressure in

point U

or:

where

D

p

m

= measured pressure in point F – measured pressure in

point A

PLANNING ADVICE

In a rotary heat exchanger it is not possible to completely eliminate

leakage between supply air and extract air. Air leakage at the seals is

minimised by keeping the pressure difference between the supply air

and extract air ducts as small as possible.

Also check the pressure balance between supply air and extract air.

Lower pressure on the supply air side can result in the transfer of

moisture and odour. This is especially important if Forced mode is

used.

The pressure at point T should be higher than at point F.

The pressure at point U should be higher than at point A.

F

T

A

U

T

F

U

A

ADJUSTMENT

NOTE! Flow deviations of up to 25% may occur when

this measurement method is used on a unit with a

rotary heat exchanger.

The measured flow values should only be regarded as

indicative. Always perform control measurement in the

supply and extract air devices.

The picture shows an RDKS-2 unit.

T = Supply air F = Extract air

U = Outdoor air A = Exhaust air