HyPower-Geko

Commissioning

FläktGroup DC-2014-0022-GB 2018-05/R5 • Subject to modifications

111

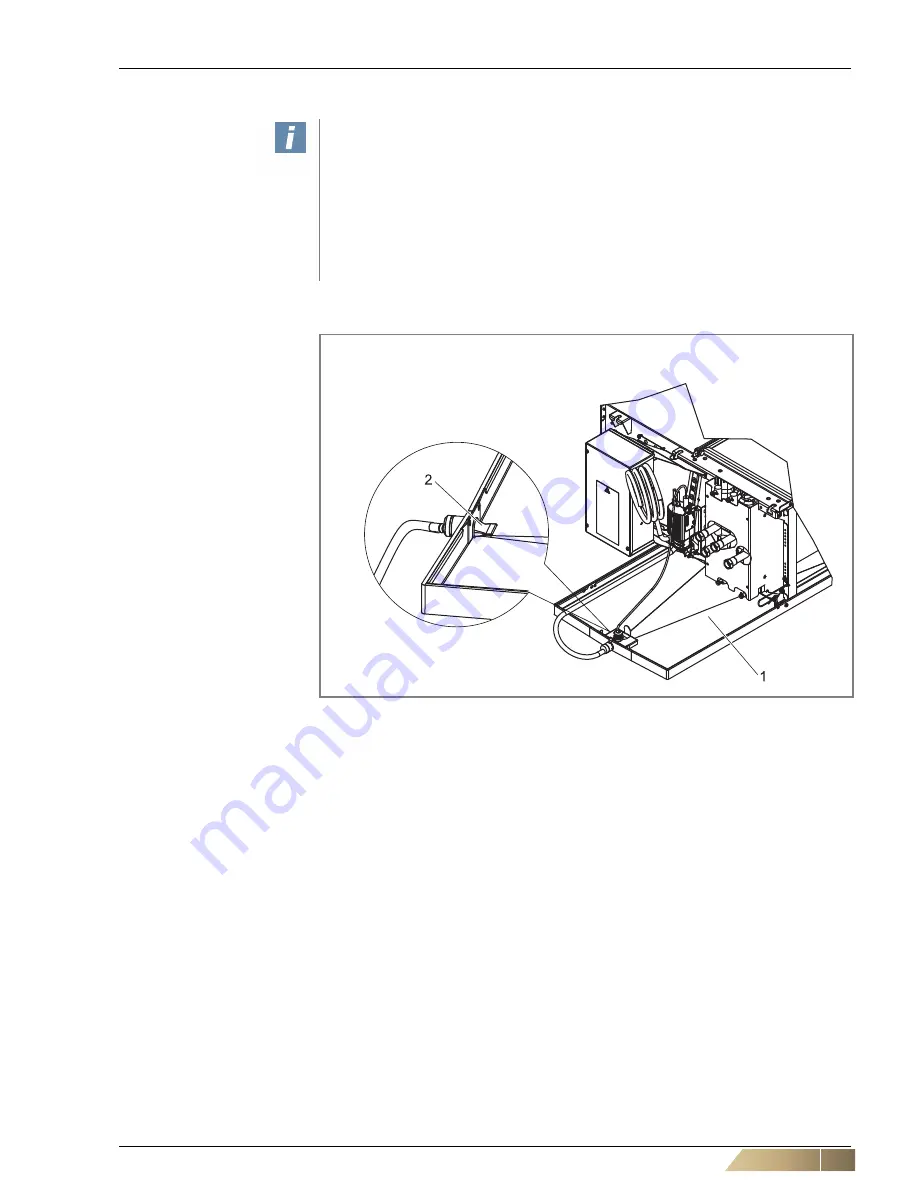

7.11 Check condensate pump (applies only to cooling units with condensate pump)

Condensate forms as a result of unit operation in cooling mode, the same applies to

non-insulated pipes.

Pos. 1:

Coil drip tray

Pos. 2:

Suction basket

•

Check

– that the coil drip tray is properly secured and stable.

– the suction basket (fig. 7-13, pos. 2) is clean and has a firm seat.

•

Unless already done, apply mains supply voltage.

•

Checking condensate pump function

– Carefully fill the drip tray with some water

(fig. 7-13, pos. 1) until the pump switches on.

– After some time, when the water is drained, the pump must switch off again.

– At this point, increase the water supply to activate the alarm sensor (fan must

switch off and cooling valve close)

•

Check all hydraulic connections for tightness during this test phase.

User instructions!

Lay the pressure lines so that no structure-born vibration can be transferred to the

basic unit or to on-site facilities

Prior to commissioning, ensure that

– the unit discharge (heat exchanger)

– coil drip tray and suction tube of the condensate pump

– and filter are clean.

If necessary, these components must be cleaned or filter medium replaced.

Fig. 7-13: Check condensate pump