Roofmaster STEC non-insulated version - Installation and maintenance

6

FläktGroup DC_10082GB_20180213_R1

Specifications are subject to alteration without notice

5 INSTALLATION

5.1 FAN INSTALLATION

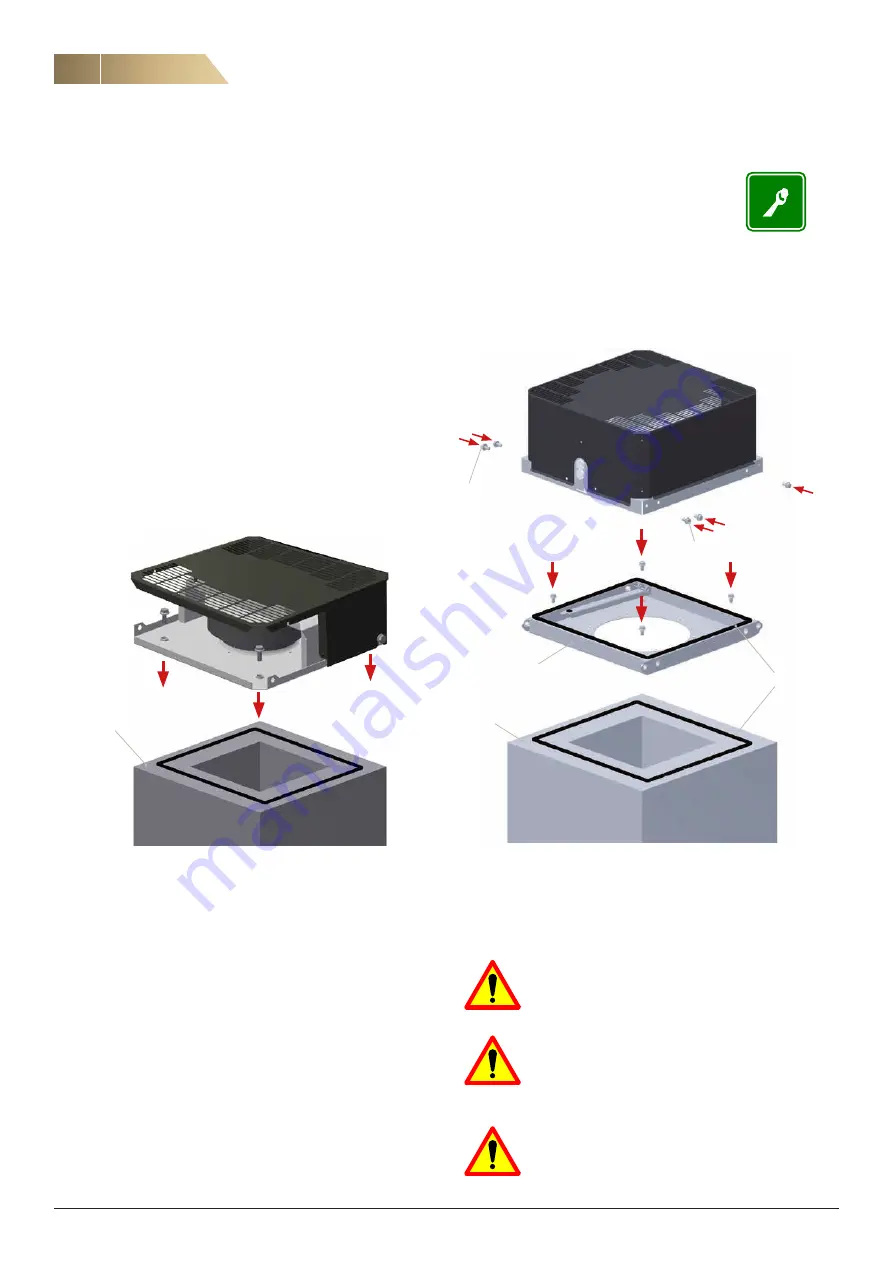

The fan can be installed on a roof curb or directly on a base

frame (size 190), or by using a mounting frame (included in deliv-

ery, sizes 225…630).

5.1.1 SIZE 190

1. Fasten the sealing tape (included in delivery) to the base

frame/roof curb or to the bottom plate of the fan.

2. Place the fan on the base frame/roof curb and fasten it

through the bottom plate with four bolts. If the base frame is

made of concrete use anchor bolts. There are four Ø12 mm

holes for screws in the bottom plate. Holes can be accessed

by removing the roof panel or the entire outer casing by loos-

ening screws or M6 bolts on both sides of the fan.

5.1.2 SIZES 225 - 630

1. Detach the mounting frame from the fan (M8 bolts on both

sides of the fan).

2. Fasten the sealing tape (included in delivery) to the base

frame/roof curb or to the bottom of the mounting frame.

3. Place the mounting frame on the base frame/roof curb and

fasten it with bolts. If the base frame is made of concrete, use

anchor bolts. There are four Ø12 mm holes (eight Ø12 mm in

size 630) for bolts in the mounting frame.

Note that:

- Possible wind load and hinges can generate high loads to the

fastenings.

- Safety switch and cable grommet shall be on the same side of

the fan. This defines also the position of the hinges.

5.2 SAFETY INSTRUCTIONS

The fan fulfills the requirements of the CE marking defined in

the Machinery Directive. The fan must be installed following the

standard EN 292/294.

The electrical installations should only be carried out

by authorized personnel.

Switch off the power and wait 5 minutes before start-

ing the installation or maintenance work. Be sure that

the fan cannot be started unexpectedly while work in

progress.

The fan delivery does not include any inlet guard. If

the installation method requires, inlet opening must

be protected.

4. Fasten the sealing tape (included in delivery) to the upper part

of the mounting frame.

5. Fasten the fan to the mounting frame with M8 bolts.

Base frame or

roof curb BOGA

Hinge bolt

Hinge bolt

Mounting frame

(included in delivery)

Sealing

Base frame or

roof curb BOGA