11

OWNER’S MANUAL

NEUTON™

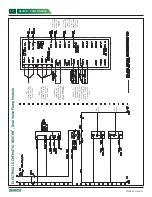

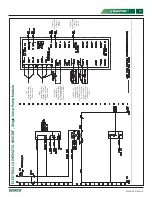

2-10 VDC

24~

COM

Belimo

TR24-SR-T US

HWR

FROM CHILLED

BEAM LOOP

Belimo

TR24-SR US

CWR

CWS

HWS

COM 24~ 2-10 VDC

P/T

Port

P/T

Port

ISO VLV

UNION

UNION

ISO VLV

CHECK

VALVE

CHECK

VALVE

PUMP

TO CHILLED

BEAM LOOP

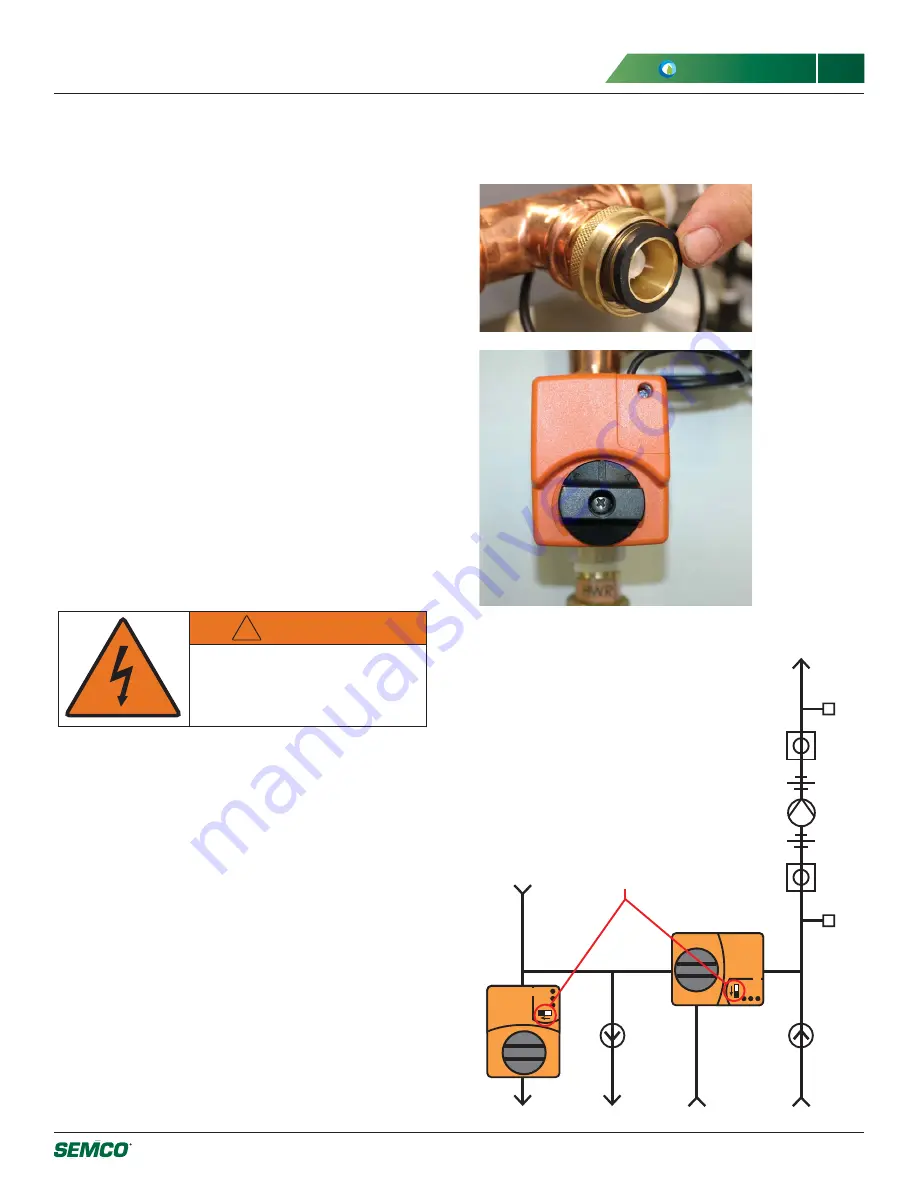

Rotation Direction

Switches

venting is complete .

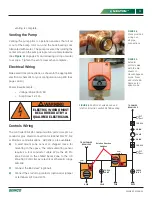

Venting the Pump

Venting the pump prior to operation ensures that all air

is out of the pump rotor can, and the back bearings are

lubricated with water . The pump is vented by rotating the

center screw on the pump a single turn counterclockwise

(See

Figure 11

on page 25) and allowing a drop of water

to escape . Tighten the vent screw when complete .

Electrical Wiring

Make electrical connections as shown in the appropriate

electrical schematic for your configuration rung 103 (See

pages 12-13) .

Power Requirements:

• Voltage: 208-230/1/60

• Amp Draw: 1 .2 FLA

!

WARNING

ELECTRIC WIRING MUST

BE CARRIED OUT BY A

QUALIFIED ELECTRICIAN.

Controls Wiring

The controller RS-485 communication ports accepts a 2

conductor plus shield connection for BACnet MS/TP, N2,

or Modbus communications . ARC156 is also available .

6)

A wall mount zone sensor is shipped loose for

mounting in the space . The communicating sensor

requires a four conductor cable . Wire the ZS Pro

Zone Sensor in the chilled beam zone to the I/O

Zone 583 Controller per electrical schematic rungs

129-132 .

7)

Connect the BACview

6

(optional) .

8)

Connect the start/stop contacts (optional) or jumper

at terminals 1370 and 1371 .

FIGURE 4.

Place provided

o-rings on

all pipe

connections .

FIGURE 5.

Actuator

control valve

with the dial

shown in

closed/bypass

mode . Press

and rotate 90

degrees for

open mode .

FIGURE 6.

Position of valve knob and

rotation direction switch AFTER venting .