GLEB Kitchen exhaust fan

5

A

ll

ri

g

h

ts

r

e

s

e

rv

e

d

.

V

e

rs

io

n

1

1

/2

0

1

2

©

F

lä

k

t

W

o

o

d

s

Oy

3.3 Fan and motor range

Fan code

Motor code

Motor IEC

Max. speed

[rpm]

Motor power

[kW]

Voltage

[V]

Current

[A]

Max. frequency

[H z]

GLEB-1-025-3-037-0 APAL-2-00037-1-2-6

71

2900

0,37

3x230/3x400 1,68/0,97

51,8

GLEB-1-031-3-055-0 APAL-4-00055-1-2-6

80

2200

0,55

3x230/3x400 2,74/1,58

78,6

GLEB-1-040-3-110-0 APAL-4-00110-1-2-7

90

2020

1,1

3x230/3x400 4,50/2,60

70,1

GLEB-1-050-3-220-0 APAL-4-00220-1-2-7

100

1770

2,2

3x230/3x400 8,16/4,71

61,7

GLEB-6-025-3-037-0 APAL-2-00037-1-2-6

71

2900

0,37

3x230/3x400 1,68/0,97

51,8

GLEB-6-031-3-055-0 APAL-4-00055-1-2-6

80

2200

0,55

3x230/3x400 2,74/1,58

78,6

GLEB-6-040-3-110-0 APAL-4-00110-1-2-7

90

2020

1,1

3x230/3x400 4,50/2,60

70,1

GLEB-6-050-3-220-0 APAL-4-00220-1-2-7

100

1770

2,2

3x230/3x400 8,16/4,71

61,7

3.4 Frequency converters and safety switches for fans

Fan code

Motor code

Frequency converter

1x230 V

Max. Input

current [A]

Frequency converter

3x400 V

Max. Input

current [A]

Safety

switch

GLEB-1-025-3-037-0 APAL-2-00037-1-2-6

STYR-14-1-11-d-1

6,1

STYR-14-3-12-d-1

2,1

SAFE-1-0-0

GLEB-1-031-3-055-0 APAL-4-00055-1-2-6

STYR-16-1-11-d-1

11,6

STYR-16-3-12-d-1

2,1

SAFE-1-0-0

GLEB-1-040-3-110-0 APAL-4-00110-1-2-7

STYR-18-1-11-d-1

18,7

STYR-18-3-12-d-1

3,5

SAFE-1-0-0

GLEB-1-050-3-220-0 APAL-4-00220-1-2-7

-

-

STYR-19-3-12-d-1

4,7

SAFE-1-0-0

GLEB-6-025-3-037-0 APAL-2-00037-1-2-6

STYR-14-1-11-d-1

6,1

STYR-14-3-12-d-1

2,1

SAFE-1-0-0

GLEB-6-031-3-055-0 APAL-4-00055-1-2-6

STYR-16-1-11-d-1

11,6

STYR-16-3-12-d-1

2,1

SAFE-1-0-0

GLEB-6-040-3-110-0 APAL-4-00110-1-2-7

STYR-18-1-11-d-1

18,7

STYR-18-3-12-d-1

3,5

SAFE-1-0-0

GLEB-6-050-3-220-0 APAL-4-00220-1-2-7

-

-

STYR-19-3-12-d-1

4,7

SAFE-1-0-0

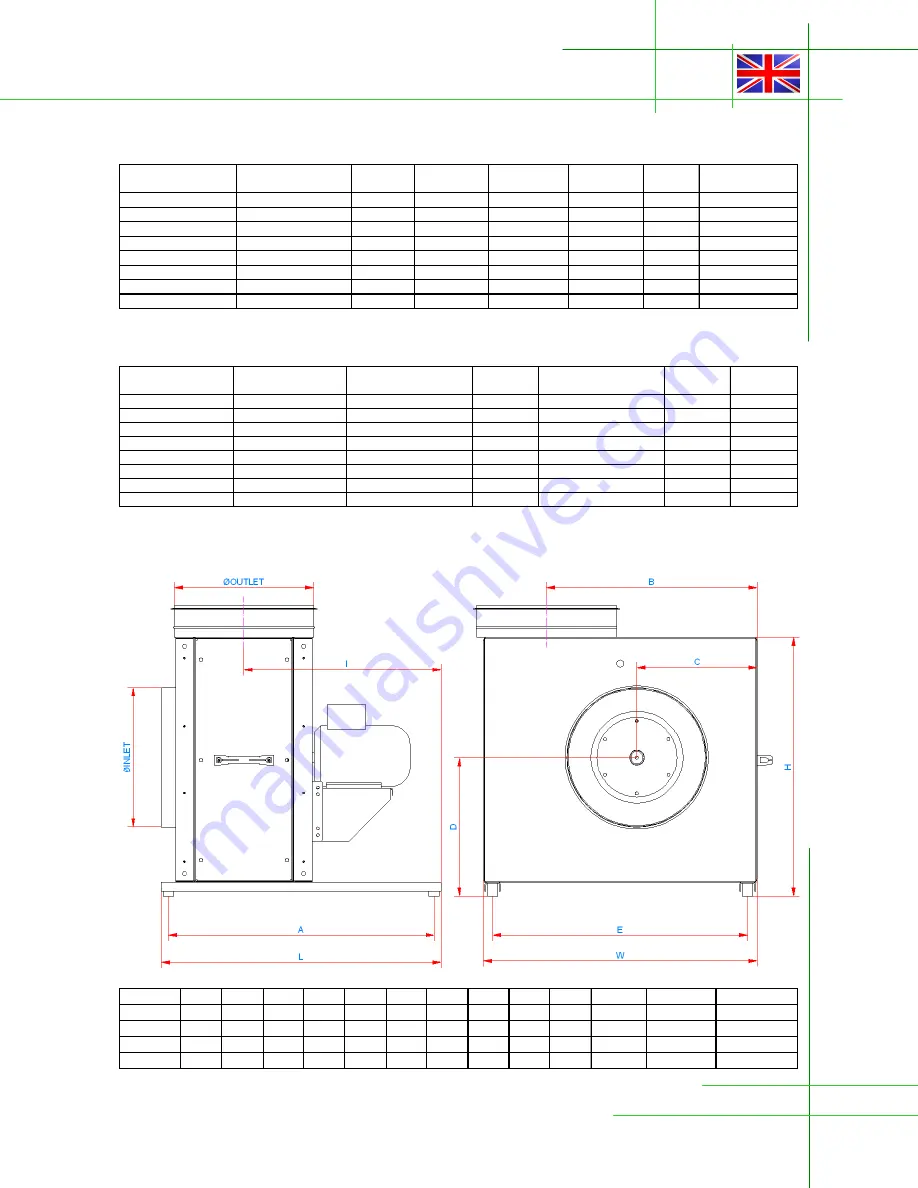

3.5 Dimensions

Fan size

A

B

C

D

E

F

H

I

L

W

ØINLET ØOUTLET Weight [kg]

025

560

388

235

282

477

39

516

414

600

527

250

250

55

031

760

465

283

332

587

39

613

592

800

637

315

315

75

040

760

603

344

396

730

92

739

564

800

780

400

400

102

050

760

737

417

472

899

92

888

528

800

949

500

500

142