© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Errors and omissions excepted.

Rev 1.0 Aug-18

Page

8

/

44

Equipment Overview

The function of this pressurisation unit is to provide a means of automated water top-up to sealed heating and

cooling systems. The equipment is designed to provide periodic water top-up to compensate for minor losses in

system pressure (e.g. slow leaks, air venting, etc.).

This equipment is not designed to cope with sudden losses of system pressure (e.g. manual

draining) or major water losses (e.g. large leaks). The equipment is also not intended to be used

for water boosting applications.

Principal of Operation

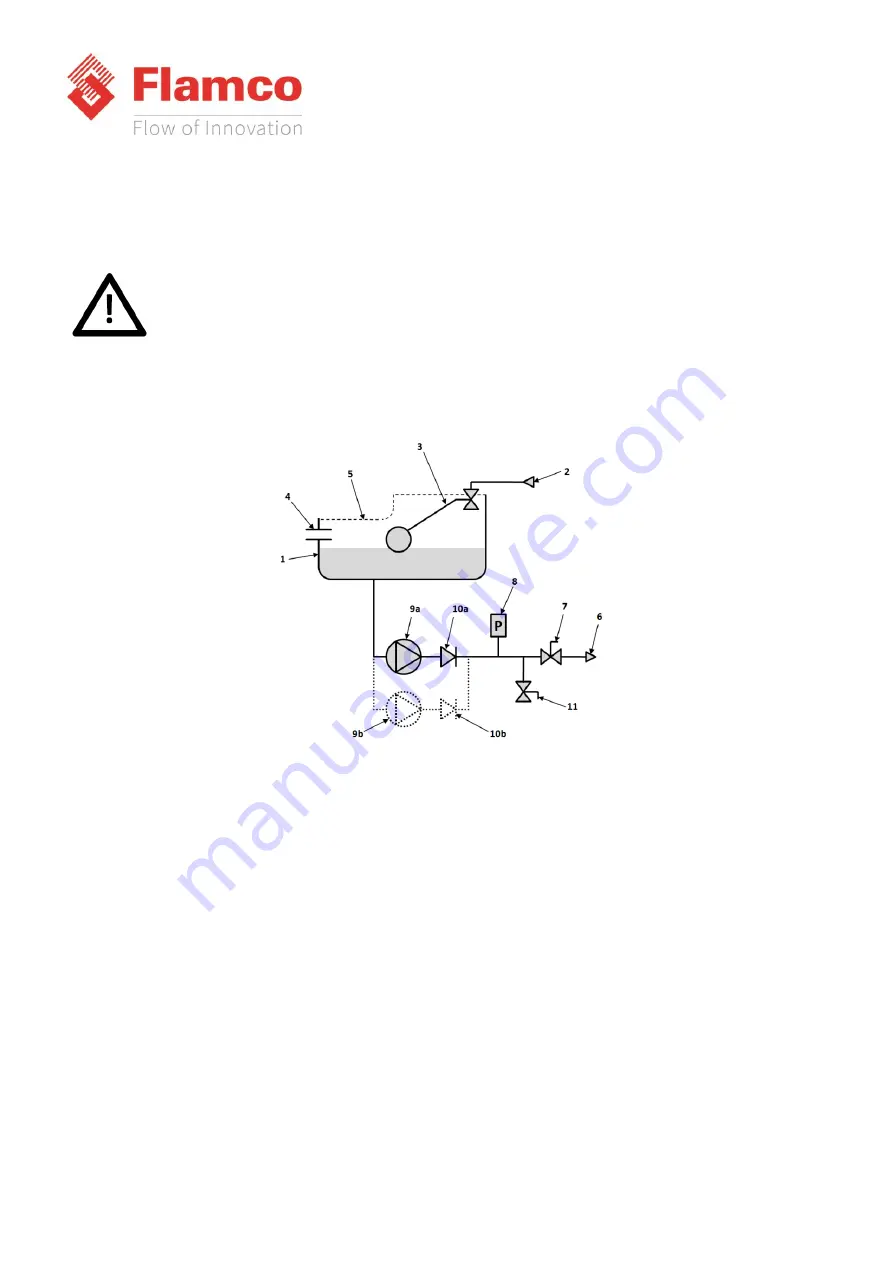

The following schematic shows the internal arrangement of a pressurisation unit:

The pressurisation unit is fitted with a break tank (1) which is filled from the mains water supply (2) via a float

operated valve (3). The break tank is fitted with a warning overflow (4) in case the break tank overfills, and a

weir overflow (5) as the primary backflow protection.

The pressurisation unit is connected into the heating system (6) via an isolation valve (7).

The pressure sensor (8) monitors the system pressure.

If the pressure sensor detects a drop in pressure, the pump (9a) will pump water from the break tank into the

system. Once the required pressure has been reached, the pump will stop.

On twin pump models, a second pump (9b) is provided. The two pumps will run in a duty/standby/automatic

changeover configuration (i.e. the active pump will alternate with each pump start).

The pump(s) are fitted with non-return valves (10a, 10b) to prevent backflow.

A drain valve (11) is provided for draining down the unit and for commissioning purposes.