1.7 MAINTENANCE

As a rule, disengage the driving system and stop the engine prior to carrying

out maintenance, servicing, cleaning or repair work.

ALWAYS

remove the

ignition key.

Chock the machine with appropriate wheel chocks before carrying out any

maintenance work.

The manufacturer will not be responsible for any damages or injuries caused

by unauthorised repair, alterations or mishandling of the product.

Maintain the product with care. Check periodically for damage that would

affect the safe operation of the Slurry Tanker.

Regularly check all bolts and tighten if necessary.

Regularly lubricate the hydraulic cylinder, bearings and drawbar hinge bush-

es using clean grease.

Only use clean grease complying to Din 51502.

ALWAYS

ensure all warning stickers are kept clean and in good condition.

CAUTION

paintwork may be damaged if high-powered washers are used

when cleaning the Slurry Tanker.

Do not carry out any welding of the tank without opening the back door.

Check tyre pressures daily. An under inflated tyre on one side will cause se-

vere stability problems on undulating ground.

VACUUM PUMP MAINTENANCE.

Periodically check the oil level in the gearbox at the front of the pump. The

oil level should be at the top of the see through plug.

Change the gearbox oil after the first 50 working hours and then every 300

working hours. Use EP90 hypoid gear oil.

Check daily that the level of the cooling oil is always above the bottom mark

on the dip stick. Top up using Battioni Vacuum Pump oil or engine oil SAE20

(SAE30 summer).

Check that the cut out valves (Primary & Secondary Float Valves) are in full

working order and that the rubber balls are not soft and spongy. These

should be replaced every 12 months.

After every working day flush out the pump with diesel oil. This will prolong

the life of the vanes in the pump. To do this set the pump to

Pressure

and

suck 1 litre of diesel in through the air intake. As a further precaution suck a

small amount of oil into the pump to lubricate it and minimise corrosion.

If the tanker is to be stored unused for a period of time then disconnect the

hose that connects the pump to the tank. This will avoid the transfer of corro-

sive gases from the tank to the pump.

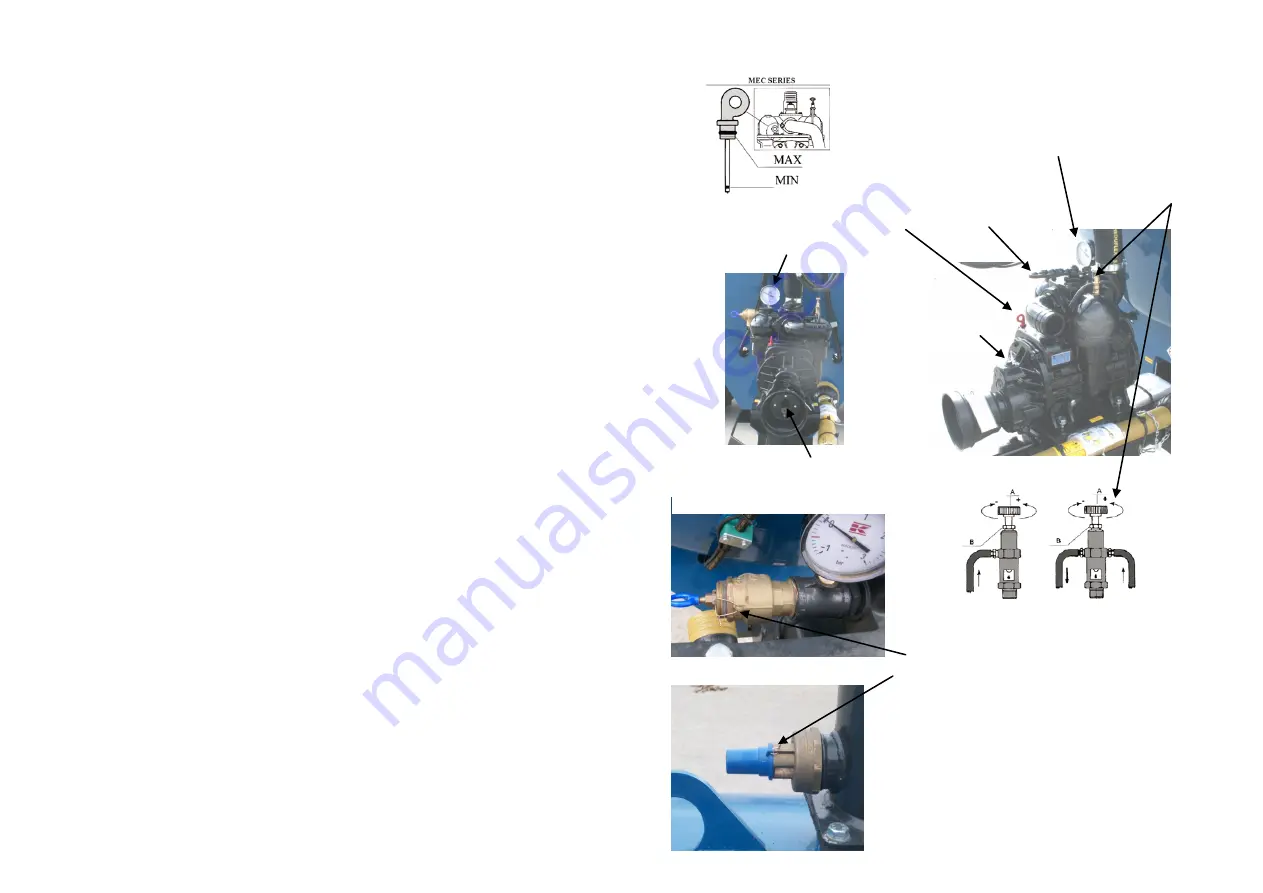

Vacuum Pump

Pressure Gauge

PTO Input

The minimum oil level is

indicated by the groove

at the bottom end of the

dipstick. Maximum is at

Oil Fill & Oil Level

Pressure Gauge

Oil Drip Feed

Pump handle.

P - Pressure

N - Neutral

V - Vacuum

Gearbox Oil Fill

Oil Drip Feed Adjustment

Loosen locknut „B‟ and turn the regu-

lator screw „A‟ until a flow rate of

one drop every three seconds is

obtained. Re-tighten locknut „B‟ after

adjustment.

WARNING

Pressure release valve comes preset at 0.9 bar and should

only be adjusted by a fully qualified service

engineer.

The decompression valve is preset at –0.7 bar and this also

should only be adjusted by qualified service engineers.

DO NOT USE THE TANKER IF THE SAFETY RELEASE

VALVES ARE NOT TIED WITH WIRE AS SHOWN IN THE

PICTURES.

SAFETY RELEASE VALVE

DECOMPRESSION VALVE

WIRE TIE