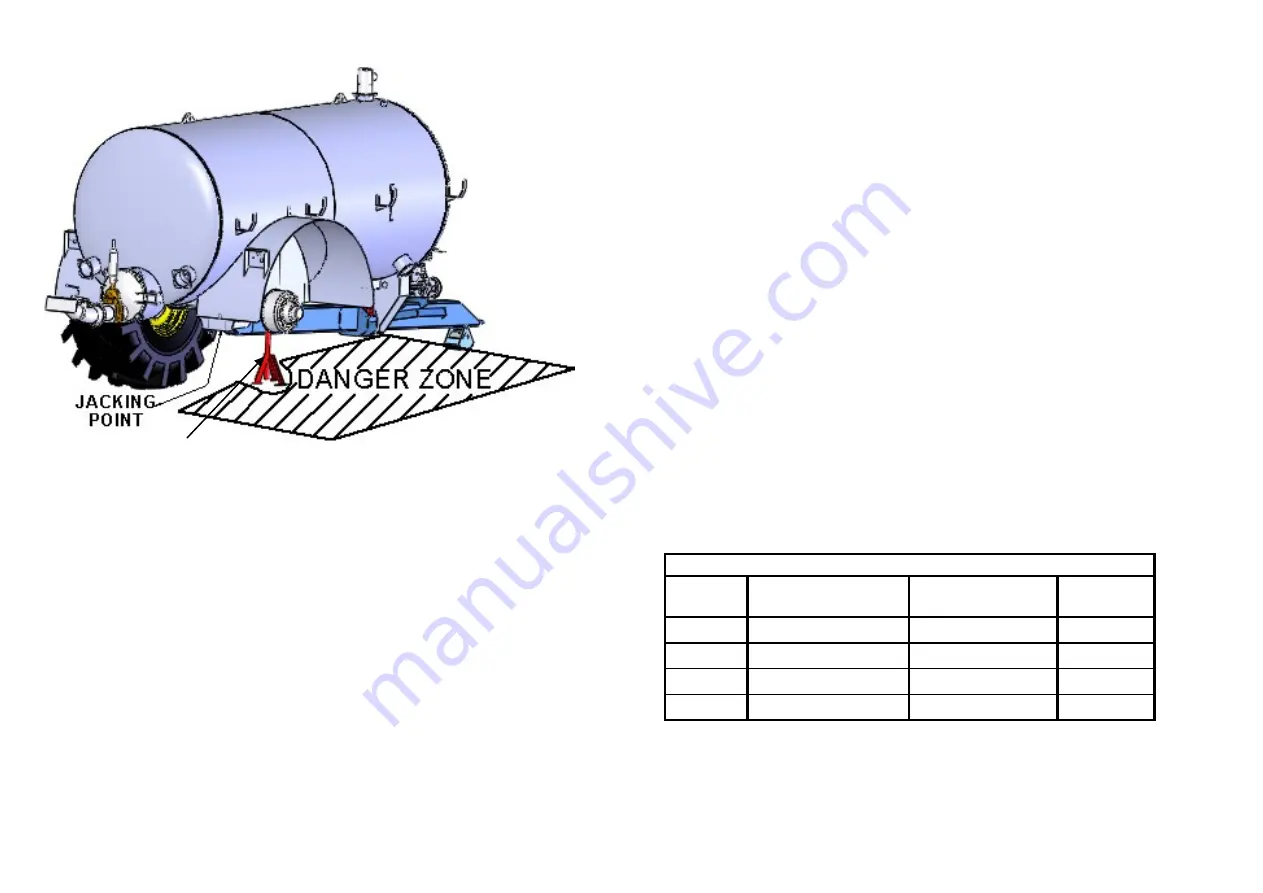

Never enter the area directly under the tanker and stand clear of the

danger zone when the wheel is removed

Prop axle with heavy duty axle stands as close as possible to the wheel

that is to be removed. Make sure the placing of the axle stand is the very

first part of the procedure and make sure the axle stand pins are of

correct specification.

Do not exceed the rated capacity of the axle stand. The weight that will

need to be jacked up will not exceed 2000kgs provided the slurry tanker

has been emptied properly.

Do not lift tanker off the ground by top crane hook when changing a

wheel.

Do not use a trolley jack or bottle jack when changing a wheel as they will

not have sufficient travel height.

AXLE STAND

1.2 AUTHORISED OPERATORS

Youths under the age of 16 must not operate the Slurry Tanker. The owner of

the machine must provide the operator with the operating instructions and

make sure they have read and understood them. Only then may the Slurry

Tanker be put into operation.

The owner must ensure that only authorised persons operate/work on this Slur-

ry Tanker. He is responsible for keeping any third persons or animals out of the

working area of the Slurry Tanker.

A SAFE DISTANCE OF AT LEAST 10M MUST BE OBSERVED BY ANYONE

WITHIN THE VICINITY OF THE SLURRY TANKER.

1.3 GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS

Before operation make yourself familiar with all elements and controls of the

Slurry Tanker as well as their functions.

Ensure the Slurry Tanker is correctly and securely attached to the operating

vehicle. The recommended method of attachment is to use the tractor hook

hitch.

Always check that the hydraulic brake line is connected and functioning.

NEVER

attach to a tractor which would be rendered unstable when the Slurry

Tanker is operated at its full capacity. Take note of the maximum load permissi-

ble on tractor draw bar.

The attaching and detaching of the Slurry Tanker to a tractor must be carried

out by only one operator. There should not be any other people in the vicinity

of the implement or in the tractor.

When detaching the Slurry Tanker from the tractor always ensure that it is safe-

ly positioned on a level surface and that blocks are positioned below each

wheel.

Table 2. Slurry Tanker Capacities

Model

Unladen Weight (kg)

Approximate

Laden Weight (kg)

Capacity

(Litres)

ST1300N

2100

8012

5910

ST1600N

2280

9433

7274

ST1600

3340

10020

7274

ST2000

3500

12250

9092