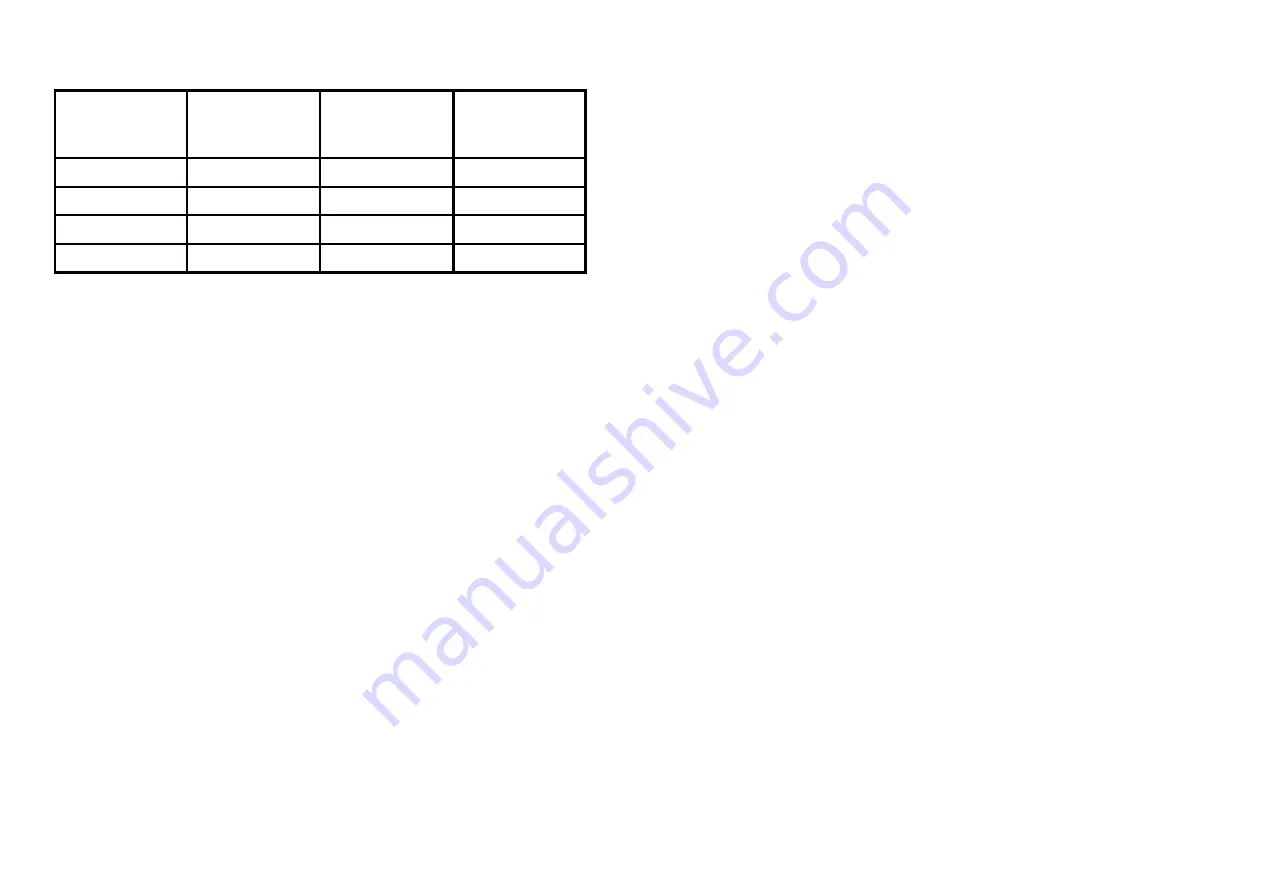

1.8 OVERALL DIMENSIONS

Model

Overall Length

(including

Sprinkler)

Width over

tyres

Height

ST1300N

6.275 metres

2.56 metres

2.65 metres

ST1600N

6.990 metres

2.56 metres

2.65 metres

ST1600

6.990 metres

2.49 metres

2.79 metres

ST2000

7 .00 metres

2.49 metres

2.99 metres

1.5 GENERAL OPERATING INSTRUCTIONS

Observe all maintenance requirements (See Section 1.7) and ensure operator

is competent with machine before commencing operations.

Before using the vacuum pump ensure that the PTO shaft is turning freely and

the direction of rotation is the same as indicated by the arrow on the pump.

Never turn the vacuum pump shaft in the opposite direction to that indicated

as this could damage internal components of the pump.

The Battioni MEC/M new series pump with long life blades may be continu-

ously operated for 15 minutes. However, prolonged uninterrupted working

times may cause excessive heating of the pump and damage to the vanes. If

it is expected that the pump will be used for a longer period because of the

density of the slurry to be processed then dilute or mix the slurry.

Operating pressure should be kept within the range of 0.5 – 0.9 bar to avoid

overheating the pump or breaking the vanes.

Do not exceed 0.9 bar

.

Ensure that oil drip feed is at the correct setting.

Regularly check the pump oil level.

Check the wheel nuts and wheel bearings daily for tightness.

Check daily that the discharge valve tongue fully opens. If it does not then re-

move the top of the valve complete with the ram by loosening the six socket

head screws securing the top valve housing to the main body. Clean out any

debris in the housing. The valve rod will break if this procedure is not carried

out.

The emergency breakaway handbrake should be connected to the tractor

every time the Slurry Tanker is used. The connection should be via a rope

attached to a solid part of the tractor such as the top link and not to a panel.

The rope should be tight enough for the handbrake to be operated if the tank-

er becomes detached from the tractor but loose enough so that the handbrake

is not applied during normal operation.