1.6 SLURRY TANKER OPERATION

Filling Procedure.

Read the sections in this manual regarding safety and maintenance.

Attach the suction filling hose to the quick attach fitting located at the rear of

the tanker.

Open the manual rear fill inlet valve with the operating handle.

Ensure that the end of the fill pipe is completely submerged before opera-

tion.

Ensure the vacuum pump oil drip feed is set to 1 drop every 3 seconds

Set the vacuum pump operating lever in the

Suction

position.

Engage the PTO at low rpm and increase to 350 rpm.

When slurry appears in the sight glass at the rear of the tanker, shut the in-

let valve with the operating handle.

Move the vacuum pump operating lever to the

Neutral

position.

Remove the suction fill pipe.

Spreading Procedure.

On arrival at the spreading site set the pump operating lever to the

Pres-

sure

position.

Engage the PTO at approximately 350 rpm while driving forward. Using the

hydraulic control, open the gate valve to the discharge unit at the rear of the

tanker.

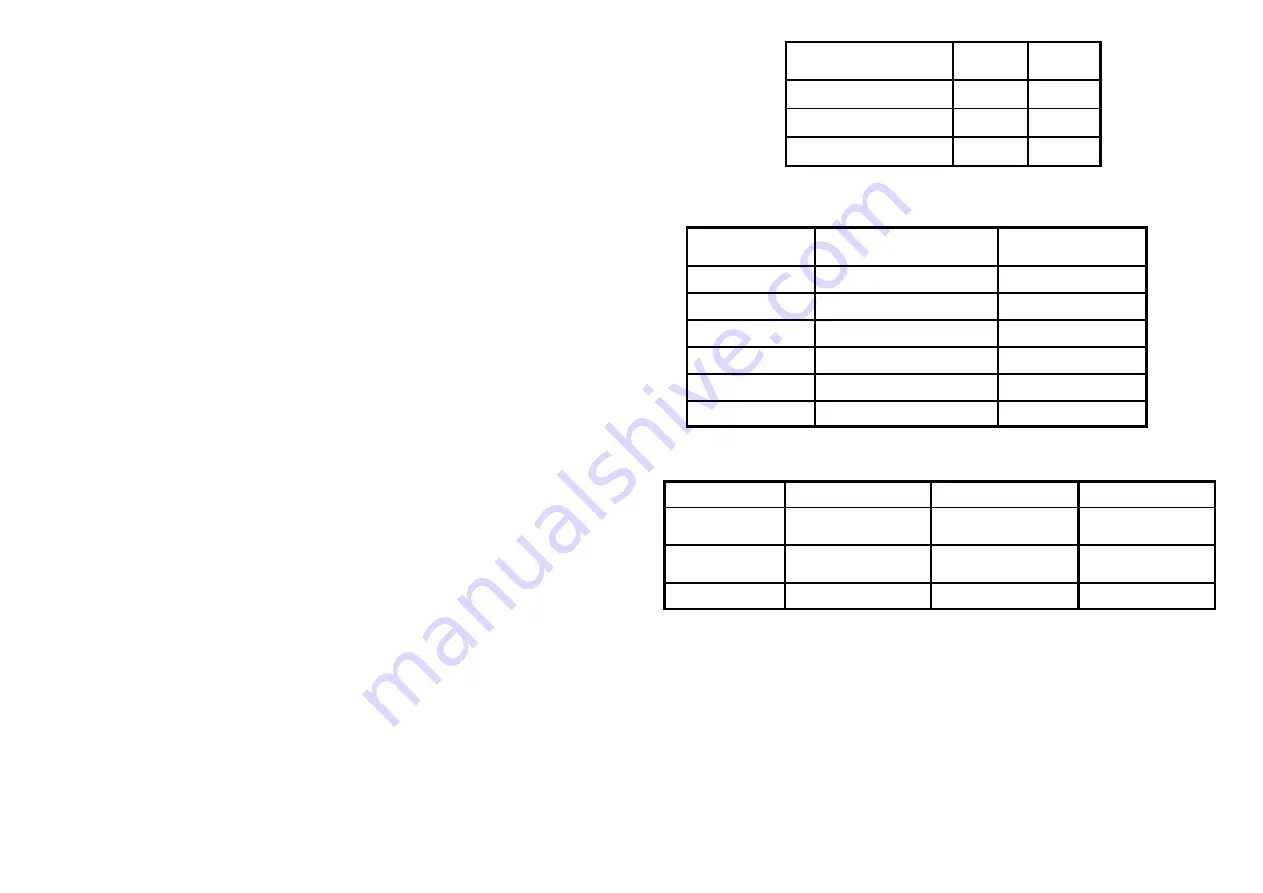

TYRE PRESSURES

RECOMMENDED LUBRICANTS

GREASE

OIL

Brake Adjustment

It is highly recommended that brake adjustment is only carried out by

qualified service engineers

.

For the safe operation of the tanker it is imperative that a routine mainte-

nance schedule is developed for cleaning, inspection, adjustment and

lubrication of brake components.

Adjustment of brakes should be carried out as frequently as required to

maintain safe operation. When resetting brakes. The hydraulic brake ram

should be 38mm – 50mm from the end of its stroke when the brake shoes

engage the hub.

At regular intervals remove the brake drums and check linings for wear and

the drums for cracks, scoring or any other form of deteriation.

Tyre

BAR

PSI

550/65-22.5

2

29

28.1 R26

2

29

Manufacturer

Recommended

Alternative

Shell

Shell Retinax LX2

Shell Retinax LX

Mobil

Mobil Grease H.P .222

Mobil Grease H.P.

Castrol

Castrol LMX

Spheerol A.P.T.Z.

Texaco

Hytex EP2

Esso

Unirex EP2

BP

Energrease LC2

Manufacturer

Application

Recommended

Alternative

BATTIONI

PAGANI POMPE

Vacuum Pump oil

reservoir

Vacuum Pump Oil

VPO005BP

SAE20 (SAE30

in summer)

Any of the

above

Vacuum Pump

gearbox

EP90 Hypoid