Assembling

5.1 Preparatory work

28

Edition 09/2022

M3302-01en

5.1.1

Milling the finished bore

5.1 Preparatory work

The diameter of the finished bore depends on the shaft used.

Recommended assigned fits

In the following table you can find the recommended assigned fits for bores with a parallel

key connection. The assigned fit m6 / H7 is especially suitable for a host of applications.

Description

Push fit

Press fit

Interference fit

Not suitable for reversing opera-

tion

Suitable for reversing operation

Shaft tolerance

j6

h6

h6

k6

m6

n6

h6

Bore tolerance

H7

J7

K7

H7

H7

H7

M7

Table 5-1:

Recommended assigned fits for bores with parallel key connection

Bore hole diameter

WARNING

Danger if the coupling fractures

If you exceed the maximum diameter of the finished bore, then this can cause the coupling

to fracture in operation. There is a risk of fatal injury from flying fragments. Bursting of the

coupling can lead to an explosion in potentially explosive atmospheres.

•

Adhere to the maximum diameters specified.

The maximum diameters are listed in Section Geometry data and weights (Page 63).

Procedure

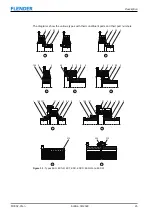

1. Remove the preservation and clean the coupling parts 1 (1) and/or 2 (2) to be machined.

2. Clamp the coupling to the areas marked with

in the diagram below.

3. Machine the finished bore in accordance with the diagram below.

Summary of Contents for ELPEX-S

Page 6: ...Table of contents 6 Edition 09 2022 M3302 01en ...

Page 8: ...List of tables 8 Edition 09 2022 M3302 01en ...

Page 10: ...List of figures 10 Edition 09 2022 M3302 01en ...

Page 14: ...Introduction 1 4 Copyright 14 Edition 09 2022 M3302 01en ...

Page 22: ...Description 22 Edition 09 2022 M3302 01en Structure ...

Page 38: ...Assembling 5 3 Aligning the coupling 38 Edition 09 2022 M3302 01en ...

Page 40: ...Commissioning 40 Edition 09 2022 M3302 01en ...

Page 46: ...Operation 7 2 Fault causes and correction 46 Edition 09 2022 M3302 01en ...

Page 56: ...Service and support 9 1 Contact 56 Edition 09 2022 M3302 01en ...