Technical data

Shaft misalignment values during operation

74

Edition 09/2022

M3302-01en

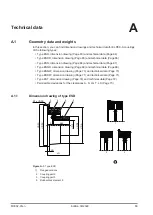

Comply with the clearances within the following limits during assembly:

A

min

= A - ΔS

A

max

= A + ΔS

S

min

= S - ΔS

S

max

= S + ΔS

LG

min

= LG - ΔS

LG

max

= LG + ΔS

T

min

= T - ΔS

T

max

= T + ΔS

LX

min

= LX - ΔS

LX

max

= LX + ΔS

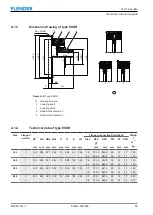

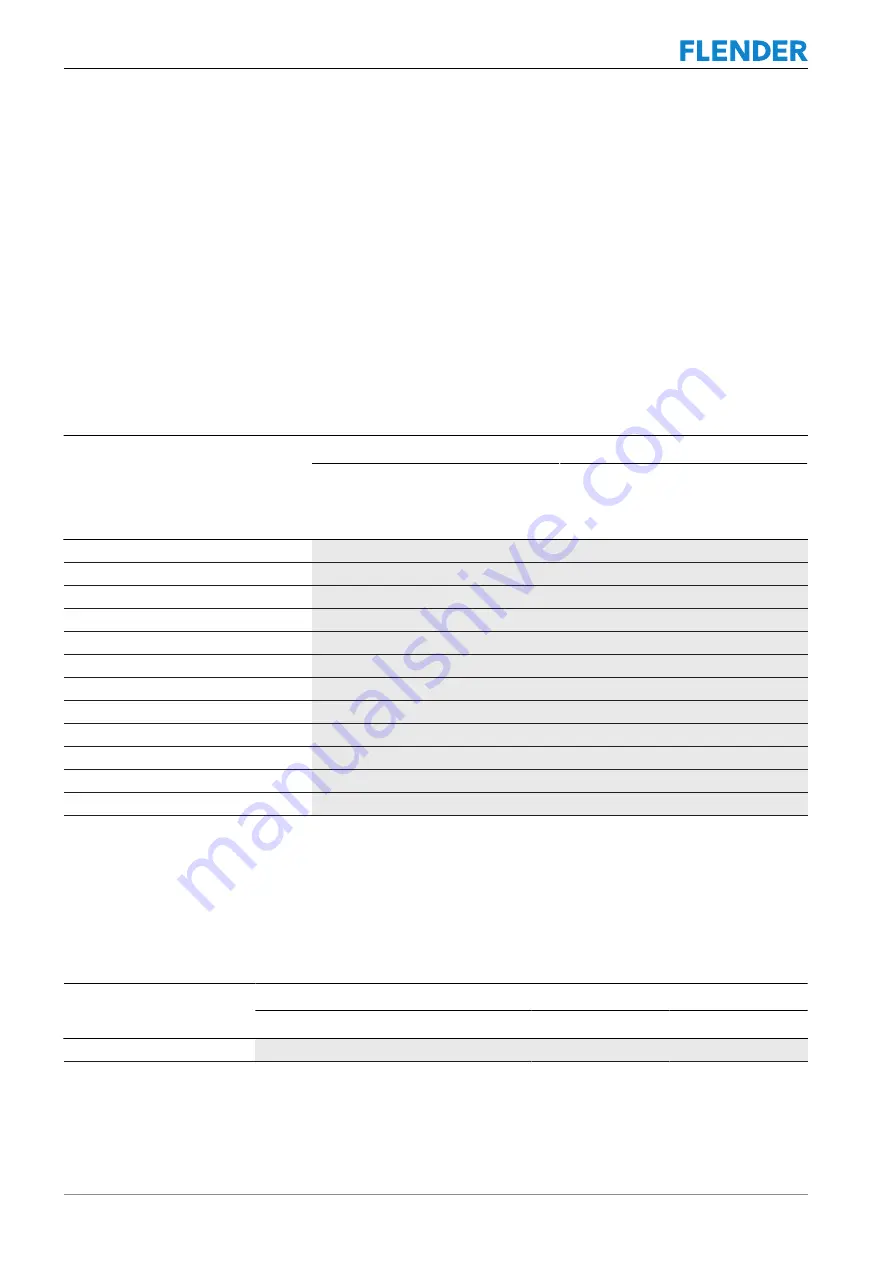

A.2

Shaft misalignment values during operation

Shaft misalignment values during operation

Maximum permissible shaft misalignments during operation ∆Kr

perm

and ∆Kw

perm

, stating the

values in mm (rounded).

Size

Permissible shaft misalignment ΔK

1500

at n = 1500 rpm

Radial

ΔKr

1500

mm

Angular

ΔKw

1500

degrees

220

1.2

0.5

265

1.2

0.5

290

1.2

0.5

320

1.2

0.5

360

1.2

0.5

420

1.3

0.4

465

1.3

0.4

520

1.4

0.4

560

1.4

0.4

580

1.5

0.3

680

1.5

0.3

770

1.5

0.3

Table A-9:

Maximum permissible shaft misalignment values during operation

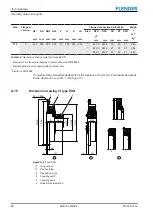

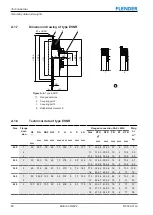

The maximum permissible radial and angular misalignment depends on the operating speed.

Use the following formulae to calculate the maximum permissible misalignment in your sys-

tem:

ΔKr

perm

= ΔKr

1500

· FKV

ΔKw

perm

= ΔKw

1500

· FKV

Speed in rpm

500

1 000

1 500

3 000

Correction factor FKV

1.2

1.1

1.0

0.7

Table A-10:

Correction factor

Summary of Contents for ELPEX-S

Page 6: ...Table of contents 6 Edition 09 2022 M3302 01en ...

Page 8: ...List of tables 8 Edition 09 2022 M3302 01en ...

Page 10: ...List of figures 10 Edition 09 2022 M3302 01en ...

Page 14: ...Introduction 1 4 Copyright 14 Edition 09 2022 M3302 01en ...

Page 22: ...Description 22 Edition 09 2022 M3302 01en Structure ...

Page 38: ...Assembling 5 3 Aligning the coupling 38 Edition 09 2022 M3302 01en ...

Page 40: ...Commissioning 40 Edition 09 2022 M3302 01en ...

Page 46: ...Operation 7 2 Fault causes and correction 46 Edition 09 2022 M3302 01en ...

Page 56: ...Service and support 9 1 Contact 56 Edition 09 2022 M3302 01en ...