27

ZAPEX 3502 en

Operating instructions 10/2017

S

Ruler

Ruler

Caliper gauge

Dial gauge

ZWH, ZWHD

With small distances "S", a ruler and caliper gauge can be used instead of a micrometer and tape measure.

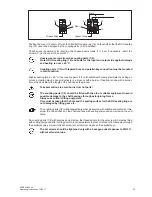

The max. permissible misalignments depend upon the duty factor, axialbacklash

limitation and coupling speed. If the speed changes, a check must imperatively be

carried out. Since misalignments (expansion due to heat, shaft deflection, settling of

foundations, etc.) can occur during operation, a misalignment of 0.1° must be aimed

for when aligning. Misalignments during alignment must, however, be no less

than 0.05°. For alignment values, see item 6.8.

6.7

Possible misalignments

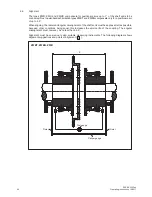

Axial misalignment

Fig. 6.4

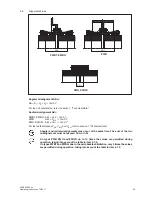

Radial misalignment

Fig. 6.6

Angular misalignment

Fig. 6.5

Δ Ka

Δ Kw

Δ Kr

Axial, radial and angular

misalignment Fig. 6.7

Δ Ka

Δ S = S

1

- S

2

S

1

S

2

Misalignments of the coupling parts in relation to one another can be caused by inaccurate alignment

during assembly, but also by actual operation of the equipment (expansion due to heat, shaft deflection,

insufficiently rigid machine frames, etc.).

The following maximum permissible misalignments must by no means be exceeded

during operation.

Summary of Contents for Zapex ZWB

Page 2: ......