16

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code

Rev.

Date saved

Date printed

U300 INSTRUCTIONS

01

09/02/2016

09/02/2016

EN

2. INSTALLATION

2.1. STORAGE

The machine, intended for indoor installation must be stored, if necessary, in well ventilated storage facilities and protected from dust.

?<*@<*!&%!%!#&&%?&#*"#$&&%*%?%!&#*&%#**#%&

**"#%%?!#$?&'$%%%?;<#%&#"%$%<>%?##&<"%$%@"#\#%%?%!<"#%$?%"@&%

oxidation caused by weather conditions.

In the case of prolonged inactivity the machine must be stored with all necessary precautions taken based on the location and expected

storage times:

1. Store the machine in an enclosed place.

2. Protect the machine from impact and stress.

3. Protect the machine from humidity and excessive temperature differences (refer to the table below).

4. Do not allow corrosive substances to come into contact with the machine.

5. Check that the pack has not been damaged and that it is perfectly dry.

"$$#**\[%?!#$?&&<#?""&$&%#&[%?%##!%'$@<#&<"%$%<##&%<$%>#%?

including rain, snow and hail, and it must be accessible exclusively to authorized personnel.

The machine is protected in such a way as to withstand the temperatures, humidity and vibration levels typically associated with transport

and storage.

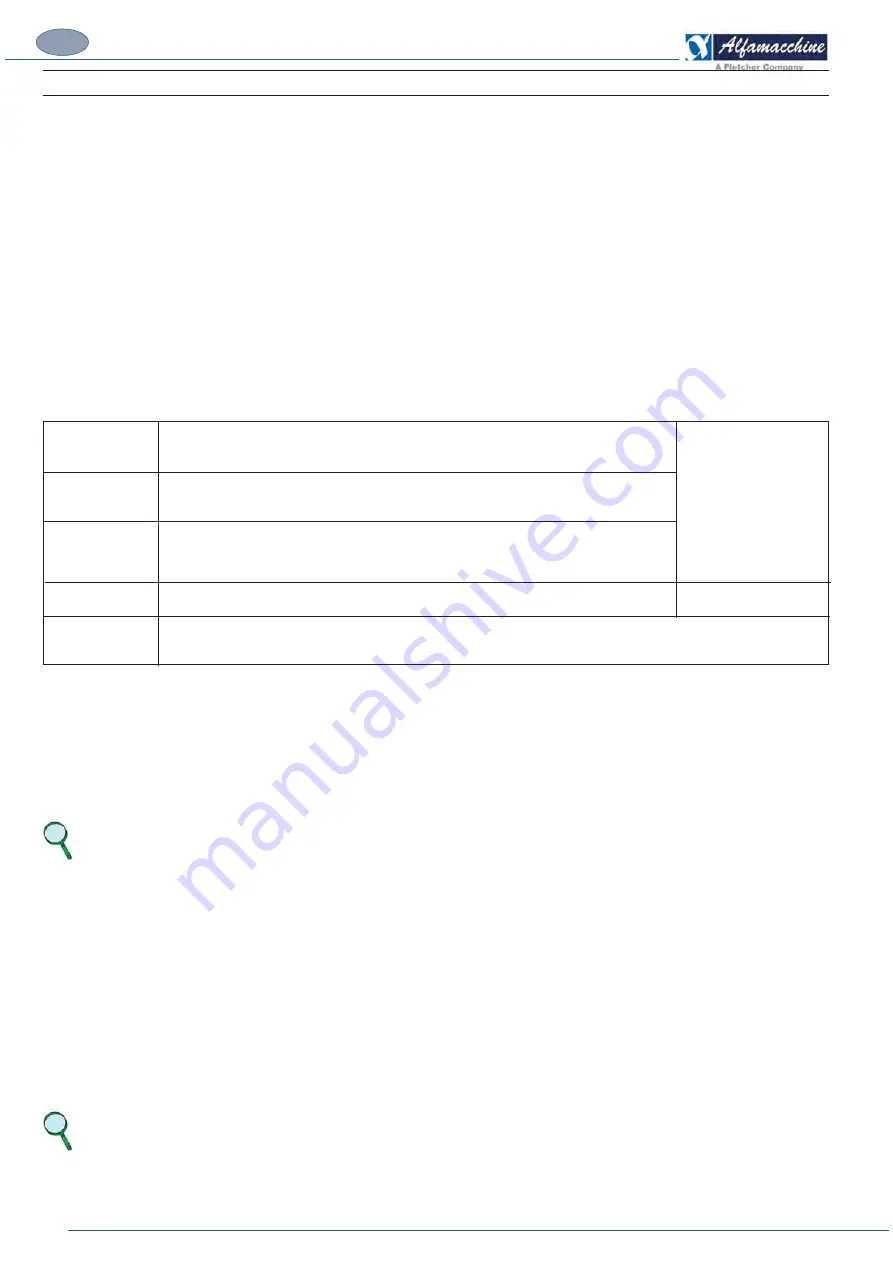

Ambient

temperature

Storing

temperature

Relative humidity

Vibrations

Atmospheric

pressure

-25 ÷ +40°C - 13 ÷ 104°F

-25 ÷ +55°C - 13 ÷ 131°F

0 ÷ +55 °C / 32 ÷ 131°F

100% at a temperature of +25°C / 77°F

Lower than 50% at a temperature of +40°C / 104°F

Lower than 90% at a temperature of +20°C / 68°F

5.9 m/s2 (0.6G) or higher 900 mbar or more

Avoid places where

there may be

unexpected changes

in temperature

which could lead

to the formation of

condensate or freezing.

Storage temperature is construed as a short-term value, e.g. during transportation. Condensation or freezing normally occurs in sites

'$%%&$#&%%!"#%;$&@&*#%@?!<%\&$?$&<%&#**>%?&%?@#*?>&&%?%#'*[*$#%&

'$%%&$#&%%!"#%$?#&?*<'#@<<

2.2.

CHECKS ON RECEPTION

NOTES

It is essential to check the packs at the time of arrival and in the precise moment in which they are received. The check is performed

in two stages for each pack received to avoid misunderstandings with the shipping agent.

Administrative check

1. Crate number and number of packs.

2. Weight and size

3. Correspondence of information on shipping document with the material effectively delivered (description, serial number, etc). The

%$?&$#*<#%#@&&%?!#$?&<&%$#%&"*#%!%$"&<>%?%?<#%@&&%?%$?&$#*<#%#""*<

4. Check correspondence between shipping document data and the order.

Technical check

1. Condition and intactness of packaging.

2. Check that the packaging shows no signs of visible damage caused during transport and handling operations.

All the above checks must be performed by inspection in the presence of the shipping agent’s delivery person. If any damage is noted

or the supply is incomplete or incorrect, inform the manufacturer’s sales department immediately.

NOTES

In relation to the above prescriptions, the manufacturer informs the user that in compliance with current international and national

rulings, goods are always shipped at the risk and responsibility of the purchaser and, unless otherwise stated in writing at the time