22

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code

Rev.

Date saved

Date printed

U300 INSTRUCTIONS

01

09/02/2016

09/02/2016

EN

+#$$#*+*='#&%(!=*<**"+<*%=#&+*))$"

The wooden work surface (not supplied) and the working bench must be aligned carefully so that the lower surface of the mouldings rest

fully on the entire support surface when the double stopper presses down on the ends of the mouldings.

?!#$?&$#&%%<>%?"$#*?*#%&&%?'#$%%""%%?>#$&%"@<<

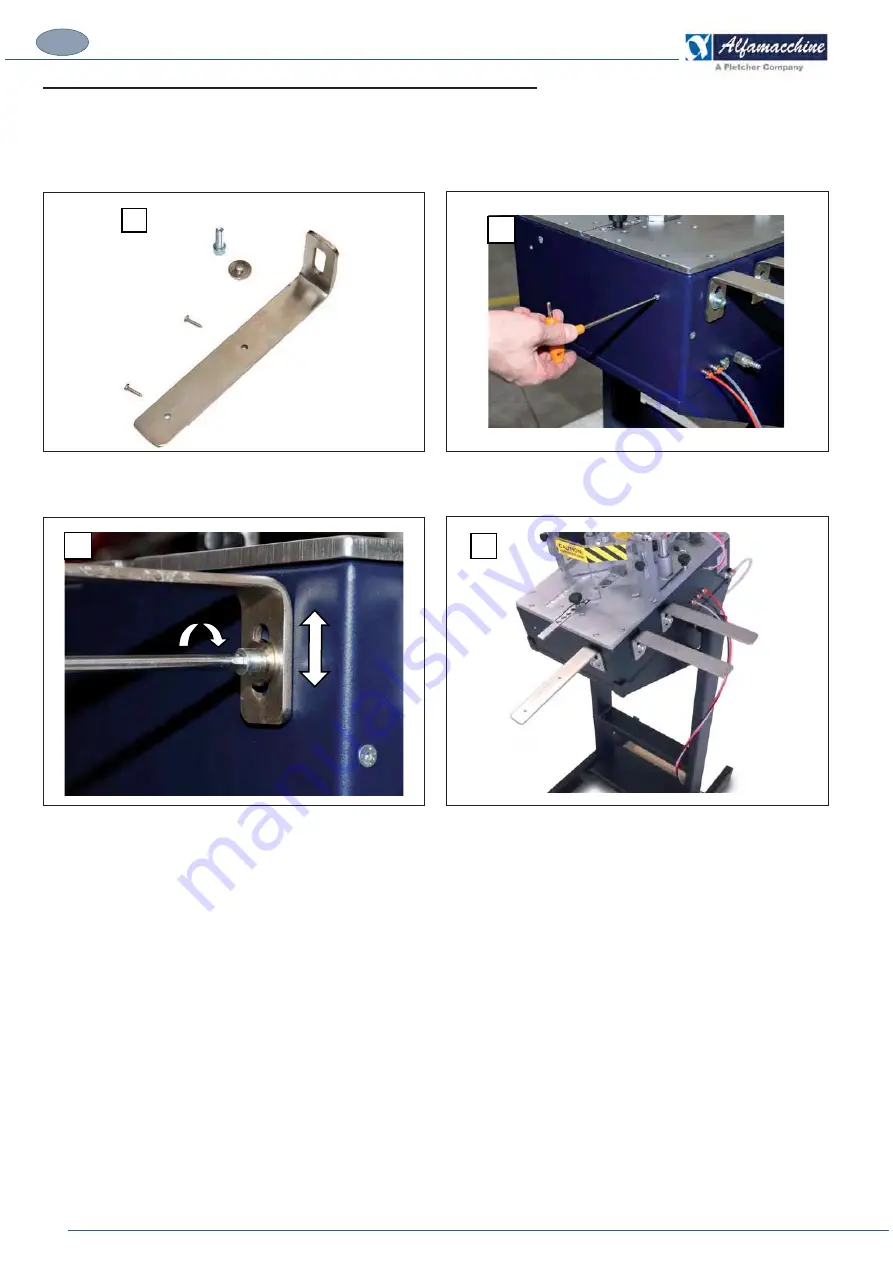

An example of how to install the brackets is provided below.

To install the extensions proceed as follows:

1. Check that each of the 6 brackets comes with the components

shown in the photo.

2. Remove the grub screws from the machine body.

3. Insert the washer with spacer and the socket head screw in the

slot on the bracket. Do not tighten until the work surface has

'&&%#**<#&<%???%<*\#<%<

4. After having installed the six brackets, place the wooden work

#$&%?!#&<#<%%???%#$?'#$%

1

2

3

4