43

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code

Rev.

Date saved

Date printed

U300 INSTRUCTIONS

01

09/02/2016

09/02/2016

EN

5.8.

TASKS THAT CAN BE PERFORMED ONLY BY MAINTENANCE TECHNICIANS

The ROUTINE MAINTENANCE operations which must be performed by a maintenance technician are indicated below.

The instructions concerning the replacement are not given in this manual and they must therefore be explicitly requested from the machine

manufacturer, which reserves the responsibility for the replacement interventions.

METHODS AND RESULTS

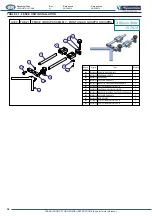

Proceed to dismantle the hammer to replace the gaskets only or

the whole piston as follows:

FREQUENCY

Every 1,000,000 V-nails

inserted

CHECK

Check / replace:

=

#%#&<?#!!

1.

Slacken the locking handle on

the stand to tilt the working bench

backwards.

Disconnect the air supply from the

machine.

2.

Disconnect the 2 pipes connected to

the cylinder.

Remove the 4 socket head screws

which secure the pneumatic cylinder

to the head.

3.

Remove the pneumatic cylinder and

extract the hammer if it is still inside

it.

Remove all traces of dirt, clean with

degreaser, check for wear, grease all

the internal surface.

4.

Replace the external head seal with

the aid of a screwdriver.

Clean the seal seat thoroughly and

grease.

5.

Replace the lip seal inside the head

with the aid of a screwdriver.

Clean the seat and the bush hole

thoroughly and grease.

6.

Remove the seals from the hammer,

clean well and grease, check for wear

or the presence of chips.

Install the new seals making sure

the lip seals are placed the right way

round.

6

1

A

2

3

4

5