14

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code

Rev.

Date saved

Date printed

U400 INSTRUCTIONS

01

02/10/2015

02/10/2015

EN

"^#'$$+=+&+

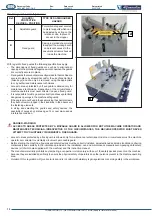

The fence unit, positioned on the working bench, can slide along

%?#!'*\*&%?&&%%"%&#<%<'\%?

operator based on the size of the moulding in relation to the position

of the front clamp (rod clamp).

The knob (C) locks the fence unit onto the working bench by means

of the clamp (E).

Once locked in place, the fence provides a stable stop guide for

$#%&%?$&%'&<

?%>!'*"#%&%#**<&*\&%?;<&$[

#%%<>%?#&'%?#%%?\$#&'%*%<&*#%&%%?

>&'&$?%?#%%?\%%?"*%?#!!*<&

better.

Fixed fences for 120° and 135° corners may also be installed in

the clamp (E) for making frames with 6 and 8 sides respectively

#@#*#'*#"%&#*#$$?%>;<&$<&%

have mobile parts (A).

The tilting fence unit with a 90° angle, for frames with 4 sides,

installed as standard equipment, is made up of the following main

elements:

*%&<%">%?#<%#'*%*%

&'#<%&%?%*%

(C) Knob for locking the fence unit.

(D) Fixed fence with 90° corner, interchangeable.

(E) Locking

clamp.

*]*+#$'$*&%+*"&$#!)

?<$*#!"}%%<>%?%>!'*#>>?$?#!@<

forward against the internal corner of the mouldings when the

operator presses the pedal thus blocking them against the fence unit.

Movement of the rod clamp is provided by a pneumatic actuator

and, as long as the pedal is pressed, it keeps the mouldings locked

in place for the entire V-nailing cycle, even when the vertical clamp

*#<%#**>!@!&%%?&&%#&<%?&%&

&#*&@#"%&#*&%?&*&

Usually the position of the rod clamp is always kept the same

>?#%@%?`%?!*<&'&&<%%?&$&%

>?$?#<%<

The front clamp is made up of:

'*#>

(H) Knob for securing the rod to the pneumatic actuator of the

front clamp.

(I)

Holes for anchoring the cursor of the pneumatic actuator.

(L)

Front locking rod clamp

A B

C

F

A B

D E

G

H

I

L