24

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code

Rev.

Date saved

Date printed

U400 INSTRUCTIONS

01

02/10/2015

02/10/2015

EN

3.4.2. Compressed air supply

The compressed air supply must be maintained in compliance with the following technical prescriptions:

=

?$!"<#""*\!%'%?%\"#&<&%&%\"$<&%?%"#%?{"&!#%$<##!~;$@

pressure values are applied the components will be irreparably damaged.

=

%#&&%#$$&%%?#$%%?#%%?!#$?&]"&!#%$\%!$&%<##$!"&&%%?<%'%&&%>[&%?

context of protection against overpressure, a protection device must be installed coordinated with the machine’s pneumatic circuit, in

compliance with legislation and the legislative and regulatory provisions in force in the country of installation.

=

?"&!#%$\%!$!"<#""*\*&!%'%<%??%?"#$"@<<'\%?#&<!%'#<j#%*\

protected.

=

?$!"<#""*\*&!%?#@#$%&#&<$?##$%%$$"&<&%%?"$$#%&?>&&%?%"#

%?{"&!#%$<##!~"*&<&%$%&%%?"$<$#&#*%"@#*#&<%?!"#$$%

operation of the machine.

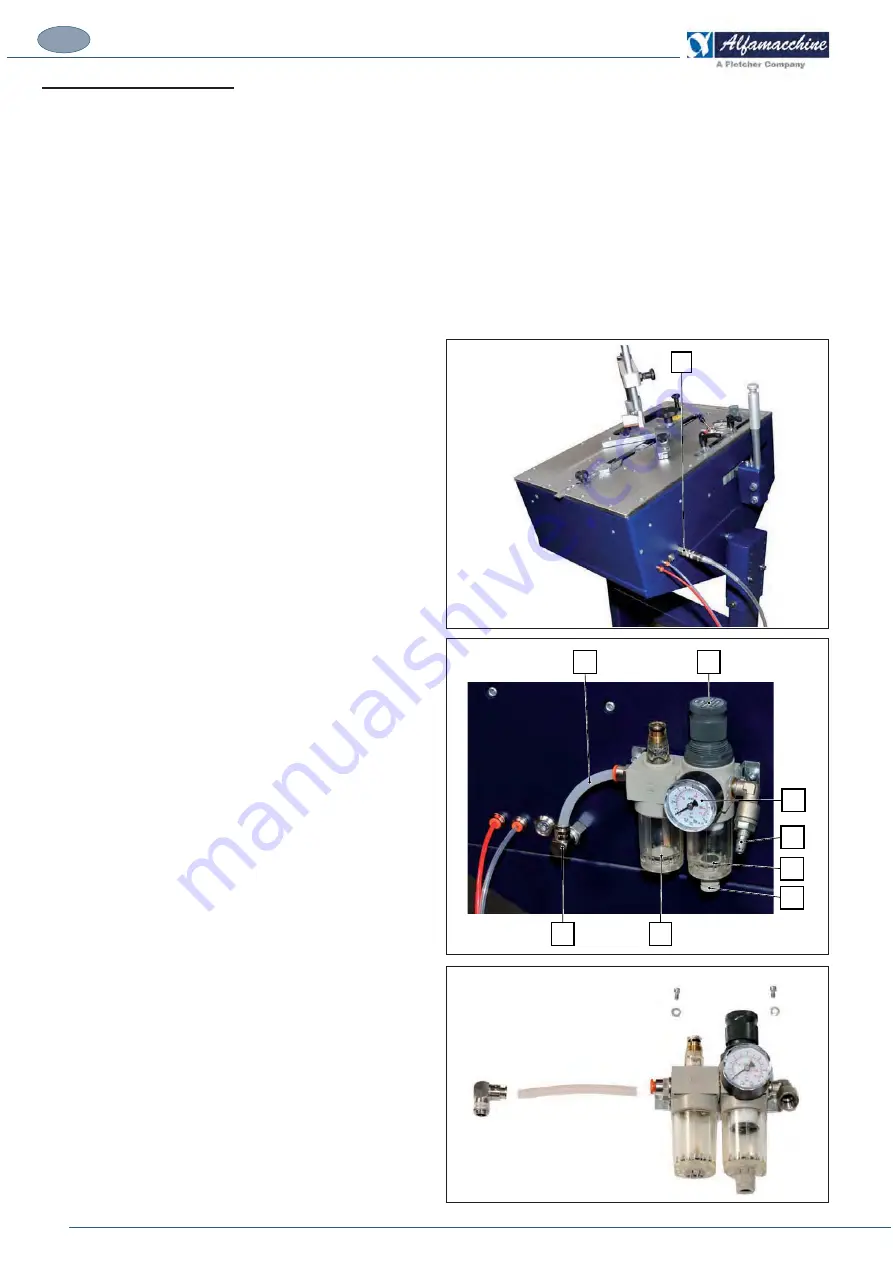

The following units are incorporated in the compressed air inlet point:

Standard supply:

$%$"*

Optional supply:

%?*%"*#%&%$#&'<<"##%*\

(B)

Rilsan air inlet pipe.

"*#%&'

""*\"#

$!"<#&*%$&&$%&"&%>%?j$%$"*

(F)

Condensate collection bowl.

(G) Discharge connection point for condensate accumulated in

the bowl.

(H) Machine air inlet connector.

}'$#&%@%'?#***<>%?*

?#*&<?>%?$!"&&%%?*%&%""*<

as an optional.

?&"%?$!"<#""*\%%?*%&%[

check that the compressed air line is of the right section for the

j<^>#%

&&$%"%?$!"<#""*\%%?&*%&%?*%

pressure regulator-lubricator unit (E).

%$&&$%&%?$!"<#""*\*&%%%&#&<

check the reading on pressure gauge (D) to ensure the value

#%*#%'#%?&%%?$#[#<%'\#$%&&%?

control knob (C).

A

C

D

B

E

F

G

I

H