Installation

10

16.

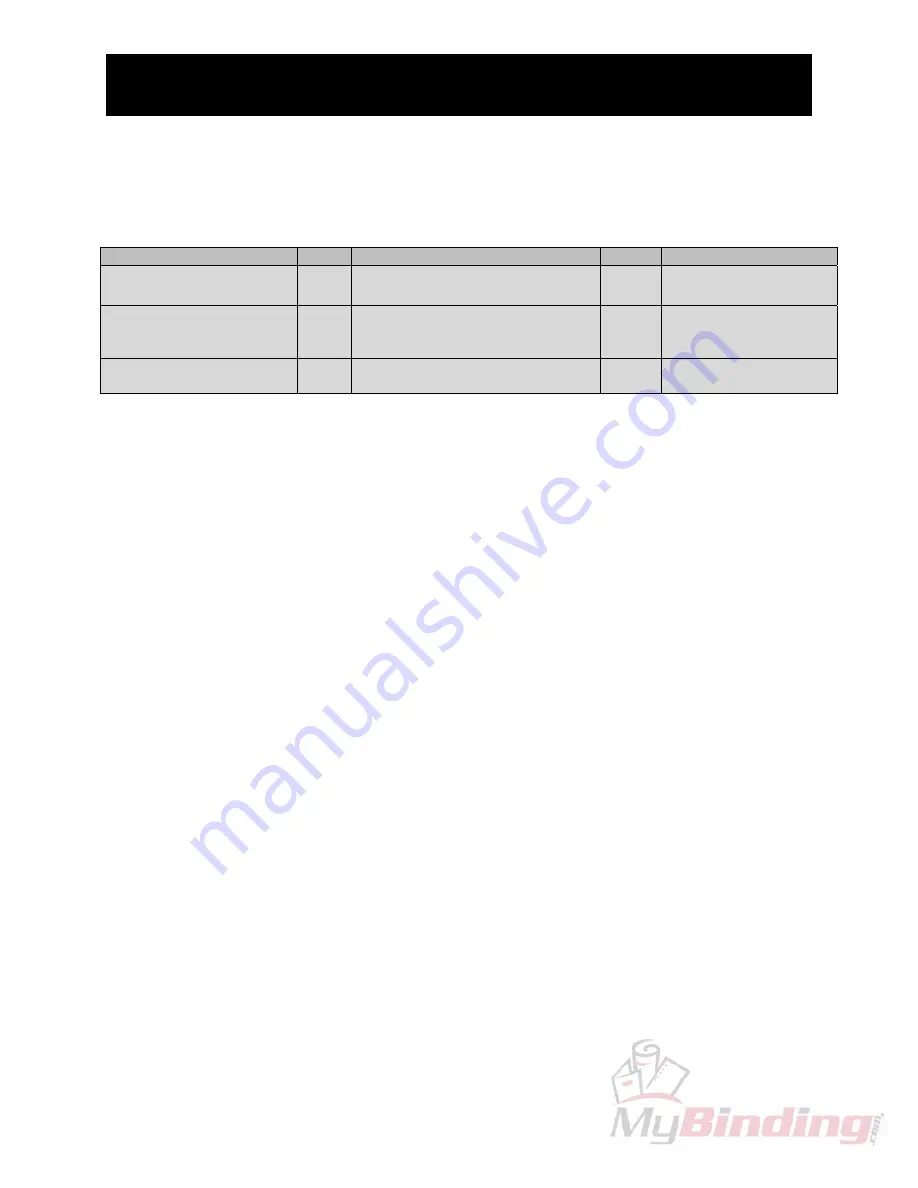

Mounting the Face Plates

Parts Needed:

Frame Parts

Qty.

Hardware

See Pg 2

Tools Needed

Small Face Plate

(Page 1 - #8)

13

M6 x 20mm Flat Head Screw

K

4mm Hex Key

Large Face Place

(Page 1 - #1)

2

4

2

M6 x 12mm Button Head Screw

M6 Flat Washer

M6 Hex Nut

H

J

I

10mm Wrench

Large Face Plate Bracket

1

Hardware is attached to bracket

P

3mm Hex Key

8mm Wrench

1.

Remove the top Screw connecting the Horizontal Brace Channel to the Vertical Track

Assembly.

2.

Position the Small Face Plate so it is nesting in the right angle made by the Horizontal

Brace Channel and the Vertical Track Assembly.

3.

Align the holes.

4.

Attach the Small Face Plate using seven (7) M6 x 20mm Flat Head Screws.

5.

Loosely tighten the Screws with your fingers.

6.

Locate the Large Face Plate Bracket.

7.

Remove the two (2) Screws that are attached.

8.

Align the vertical hole of the Bracket and the hole at the center of the long side of the Large

Face Plate.

9.

Insert the M5 x 10mm Button Head Screw (already included on the Large Face Place

Bracket). Tighten the M5 Nut and Washer using a 3mm Hex Key and 8mm Wrench.

10. Nest the Large Face Plate up against the Small Face Plate so the top diagonal of the Small

Face Plate is in contact with the bottom diagonal of the Large Face Plate.

11. Attach the top of the Large Face Plate to the Vertical Track Assembly first, then the lower

portion to the Horizontal Brace Channel using six (6) M6 x 20mm Flat Head Screws.

12. Tighten all the Face Plate Screws using a 4mm Hex Key.

¾

Tip: Reposition the Clamp Handle for easier access to the screws.

13. Secure the two Face Plates together by using two (2) M6 x 12mm Button Head Screws,

four (4) Flat Washers (one on each side), and two (2) M6 Hex Nuts in the aligned holes on

the back of the Face Plates.

¾

Tip: For Wall-Mounted Units: If you need more working room behind the machine,

remove the long M10 Hex Head Bolt holding the Front/Back Support Bars.

Lower the bars, so they push the assembled FSC away from the wall.

Remember to reposition the Bolt when you are done.

14.

Use a 4mm Hex Key and 10mm Wrench to tighten.