Cutting Tools and Substrates

19

♦

Notes:

•

Production Stop should be used if making more than one piece of the

same size.

•

Thinner materials can be cut with one pass, but thicker materials will

take more than one pass to cut through material.

28.

Scoring and Breaking Techniques for Fracture-Sensitive Material

♦

Note: It is not necessary to remove the protective coating prior to cutting.

A.

Scoring Fracture-Sensitive Material and Polycarbonate

1. Insert the Acrylic Blade Holder into the Cutting Head.

2. Lock the Holder Securing Knob.

3. Clamp the substrate in place

.

4. Depress Thumb Lever and raise the Cutting Head so the Blade is positioned

approximately 1/32" (1mm) from the top edge of the material.

5. Using the Dual Handle, pull down

slowly

to its resting position.

Note: Traveling slowly will create a smoother, more polished edge.

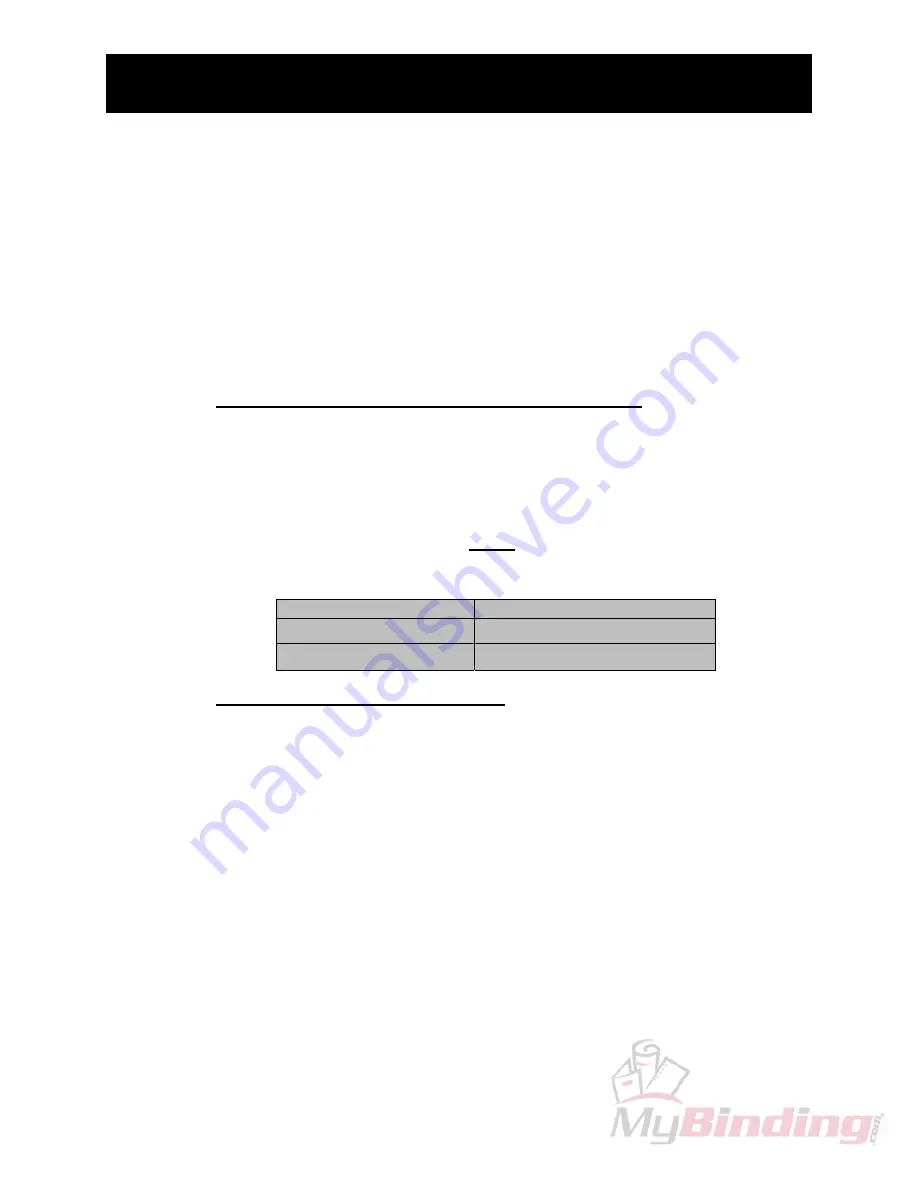

Material

Cutting Technique

⅛

" (3mm) thick

One pass with a fresh blade

¼" (7mm) thick

Make three or four passes

B.

Breaking Fracture-Sensitive Material

1. Apply pressure on the right side of the material to run the score and separate the pieces.

Note: When cutting thicker Polycarbonate material, you will need to

make multiple passes.

29.

Cutting Solid Aluminum / Aluminum-Faced Sheet Material

1.

Insert appropriate Wheel Holder into the Cutting Head.

(See “Cutting Blades and

Wheels,” Section 25 on page 16, for more information.)

2.

Raise the Cutting Head above the material, and then lock the Cutting Head in that position.

3.

Set the Production Stops to the appropriate dimension.

4.

Position the material up against the Production Stop and apply the Clamp.

5.

Unlock and lower the Cutting Head until the Cutting Wheels contact the edge of the material.

6.

Using the Dual Handle, firmly pull the Cutting Head down to its resting position.

7.

Release the clamp.

♦

Note: Do not lift up on the Cutting Head and strike the edge of the material to get

more force.