Maintenance, Adjustments,

Troubleshooting and FAQ

25

39.

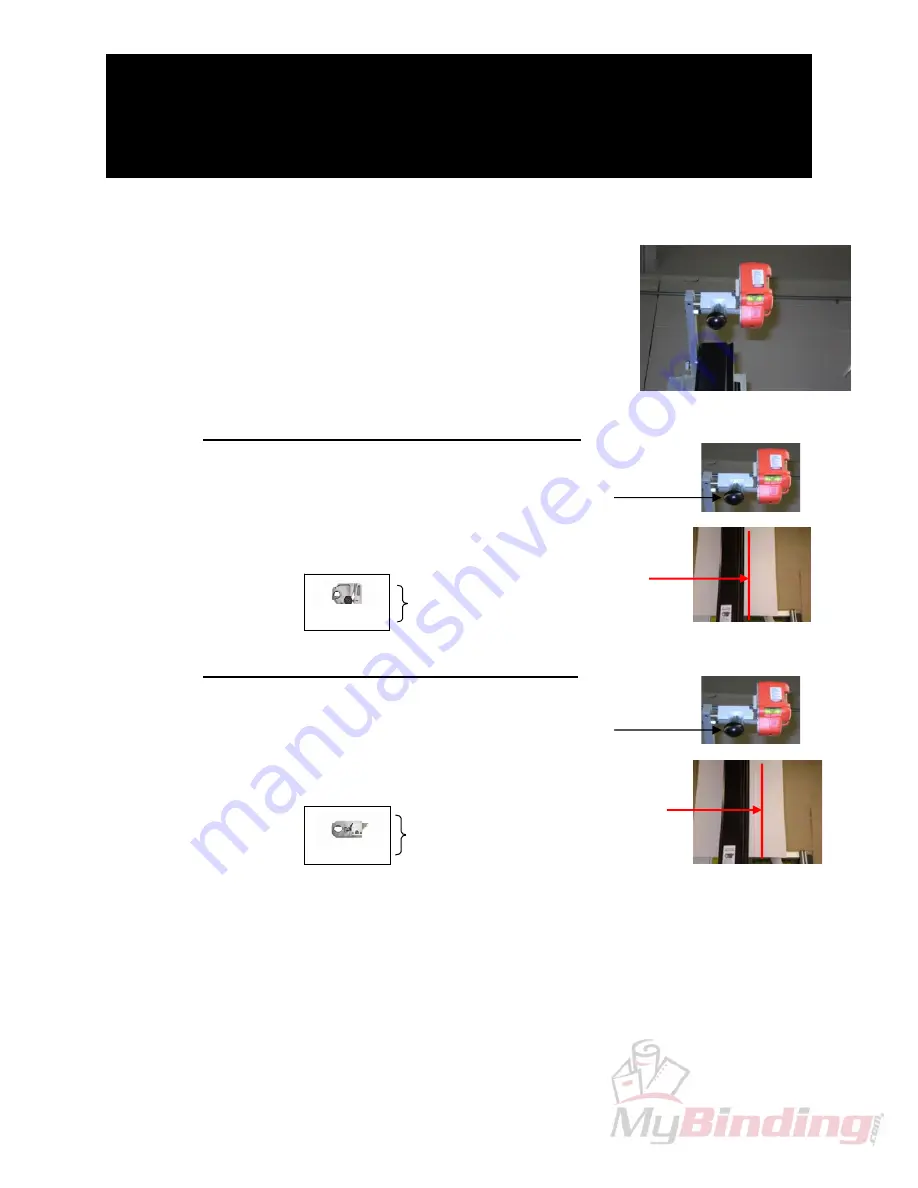

Dual Position Laser

♦

Note: The FSC cutting tool holders are sized for

cutting performance. The “wheeled” tools are

larger and provide an off-set cut line compared

to the blade tool. The Laser Assembly is

designed with a Dual Position feature giving you

the ease of positioning the Laser Sight-Line to

correspond to the cutting tool in use.

A. Positioning the Laser for use with the Wheel

(Color-coded

RED

) (Aluminum and Aluminum Composite Material)

1. Loosen the black handle by turning it counterclockwise.

2. Slide the Laser all the way to the

RIGHT

along the shaft.

3. Tighten the black handle by turning it clockwise.

B.

Positioning the Laser for use with the Blade

(

SILVER

Tools) (PVC, Foamboard, Coroplast, Acrylic)

1. Loosen the black handle by turning it counterclockwise.

2. Slide the Laser all the way to the

LEFT

along the shaft.

3. Tighten the black handle by turning it clockwise.

40.

Creating the Score Lines for Calibrating the Laser

1.

Load a piece of sacrificial foamboard onto the Horizontal Material Bar. You can use another

material if foamboard is not available.

¾

Tip: It is best to choose a softer material that will show the score lines better.

2.

Place the ½" (13mm) Blade Holder in the FSC.

3.

Create a score line the entire length of the foamboard.

4.

Remove the ½" (13mm) Blade Holder and replace it with the Aluminum Composite Wheel.

Wheeled Tools

Laser RIGHT

Blade Tool

Laser LEFT

RED

Laser Line

enlarged for

illustration only

RED

Laser Line

enlarged for

illustration only