Maintenance, Adjustments,

Troubleshooting and FAQ

26

5.

Place the Cutting Head at the top of the substrate and make a cut approximately 1" (2.5 mm)

in length.

6.

Remove the Aluminum Composite Wheel and return the Cutting Head to its resting position

at the bottom Vertical Track Assembly.

41.

Calibrating the Laser to Cut Lines

CAUTION: Use Laser Safety Goggles before turning on the Laser.

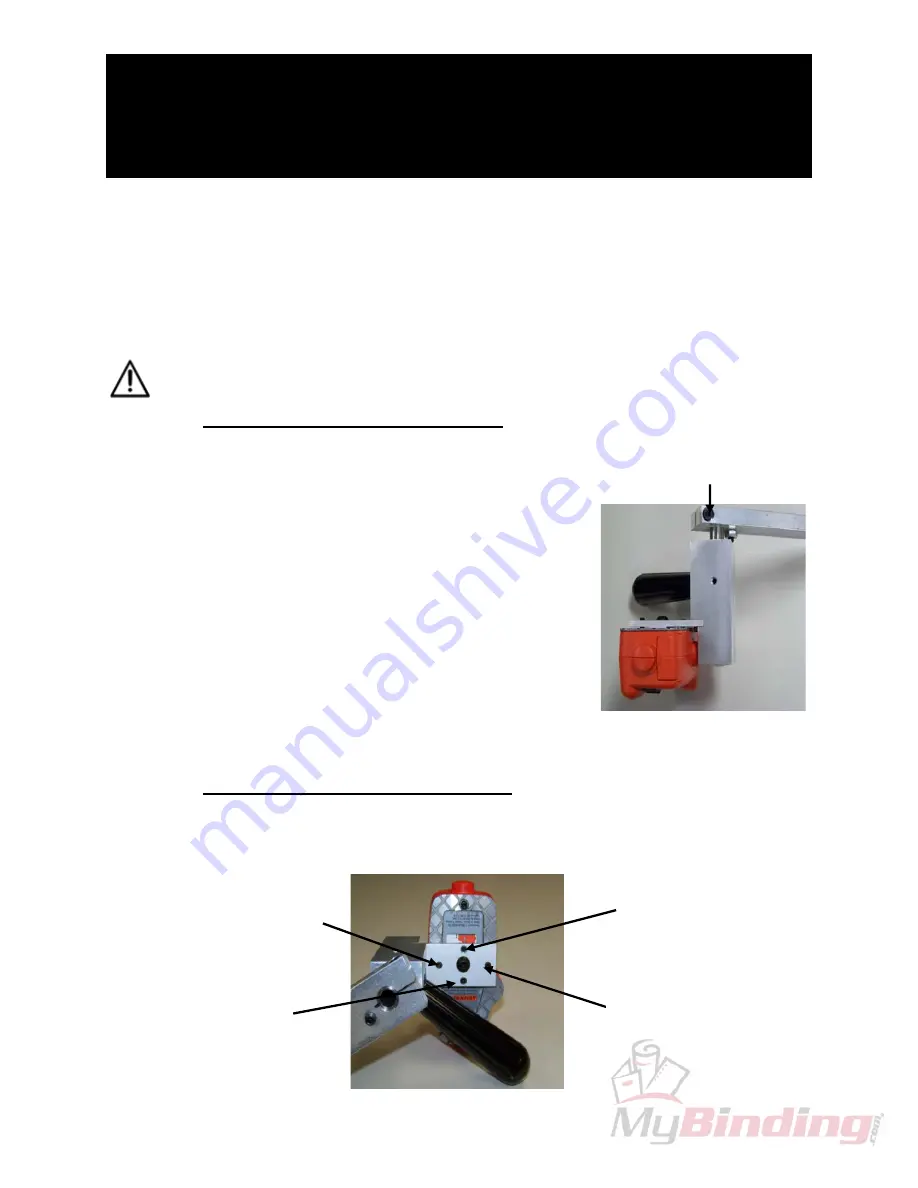

A. Creating a Continuous Laser Beam

1.

Turn on the Laser. The switch is located on the right side

of the Laser. Slide the On/Off switch down to the On

position.

2.

If Laser Beam is visible from the top of the substrate to

the bottom, skip to “Setting the Angle of the Laser

Beam,” Section 41.-B. on page 26.

3.

If the Laser Beam is not entirely visible from the top of

the substrate to the bottom:

a. Use a 4mm Hex Key, to loosen the Laser Shaft

Clamping Screw located on the top of the Laser

Shaft

(see Figure on the right).

b. Rotate the Laser using the Handle until the beam

becomes continuous from the top to the bottom of

the substrate.

c. Retighten the Laser Shaft Clamping Screw.

B.

Setting the Angle of the Laser Beam

Follow the steps below to create a beam that fall directly on top of your score line. Once

your score line is perfectly matched up with the Laser Beam, you are finished.

Top Set Screw

moves beam left

Back Set Screw

(farthest from you)

moves beam clockwise

Laser

Shaft

Clamping

Screw

Bottom

Set

Screw

moves

beam

right

Front

Set

Screw

(closest

to

you)

moves

beam

counterclockwise