-20-

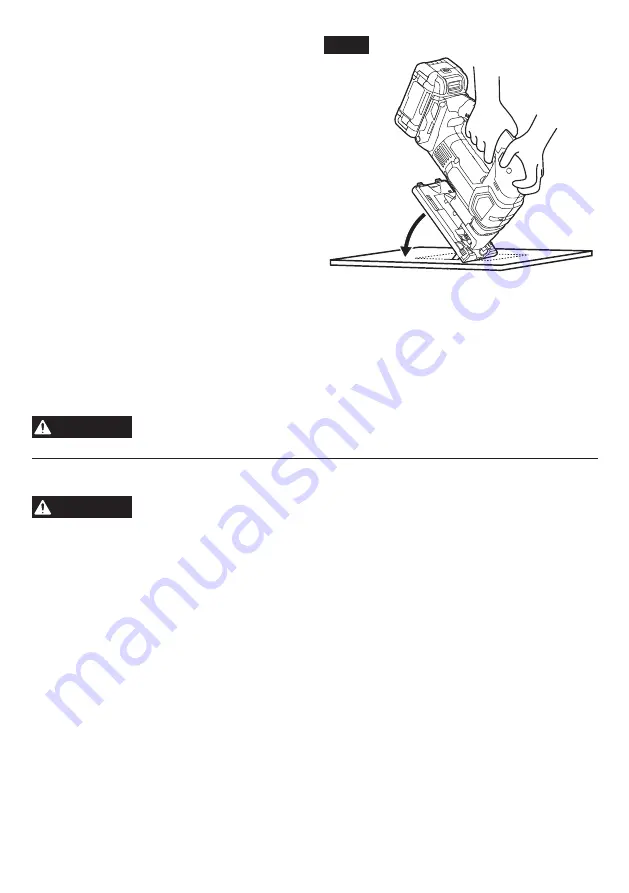

B. Plunge cutting (Fig. 27):

You do not need to drill a starting hole or make a

lead-in cut if you carefully perform the following:

a. Make sure that the base of the saw is set to

straight cut (No bevel angle.

b. Tilt the tool up on the front edge of the base

with the blade point positioned just above the

workpiece surface.

c. Apply pressure to the tool so that the front

edge of the base will not move when the tool

is switched on and slowly lower the rear end

of the tool.

d. As the blade pierces the workpiece, keep

pivoting the tool down until the base rests flat

on the workpiece.

e. Complete the cut in the normal manner

NOTICE:

We do not recommend plunge cutting

with a scroll blade.

To make sharp corners, cut up to the corner,

then stop the saw and back up slightly before

rounding the corner. After the opening is

complete, go back to each corner and cut it from

the opposite direction to square it off.

WARNING

Do not plunge cut into

metal surfaces.

METAL CUTTING

WARNING

Never use the wood-

cutting blade for cutting

metals. Failure to do so could result in

serious personal injury.

•

Clamp the material when cutting metal.

•

Be sure to move the saw along slowly.

•

Use lower speeds.

•

Do not twist, bend, or force the blade.

•

If the saw jumps or bounces, use a blade with

finer teeth.

•

If the blade seems clogged when cutting soft

metal, use a blade with coarser teeth.

•

For easier cutting, lubricate the blade with a

stick of cutting wax, if available, or with cutting

oil when cutting steel.

•

Thin metal should be sandwiched between two

pieces of wood or tightly clamped onto a single

piece of wood (wood on top of the metal).

Draw the cut lines or design on the upper

piece of wood.

•

When cutting aluminum extrusion or angle

iron, clamp the work in a bench vise and saw

close to the vise jaws.

•

When sawing tubing and the diameter is larger

than the blade is deep, cut through the wall of

the tubing and then insert the blade into the

cut, rotating the tube as you saw.

Fig. 27