Belt speed reader

Conveyor Site Preparation:

o

Identify where the device will be installed

The device requires 3-1/2” (90mm) of clearance on the pole

Placement outside OR inside the tensioner on the pole is acceptable, but it is

advised to add a pole extender to the pole before placing the device inside a

tensioner

If using a pole extender, then use care that it does not cause an undue tripping

or safety hazard on a catwalk

Placement inside a chute wall is NOT acceptable due to increased risk of

damage to the device and inaccessibility for maintenance

Place the device where it can be serviced

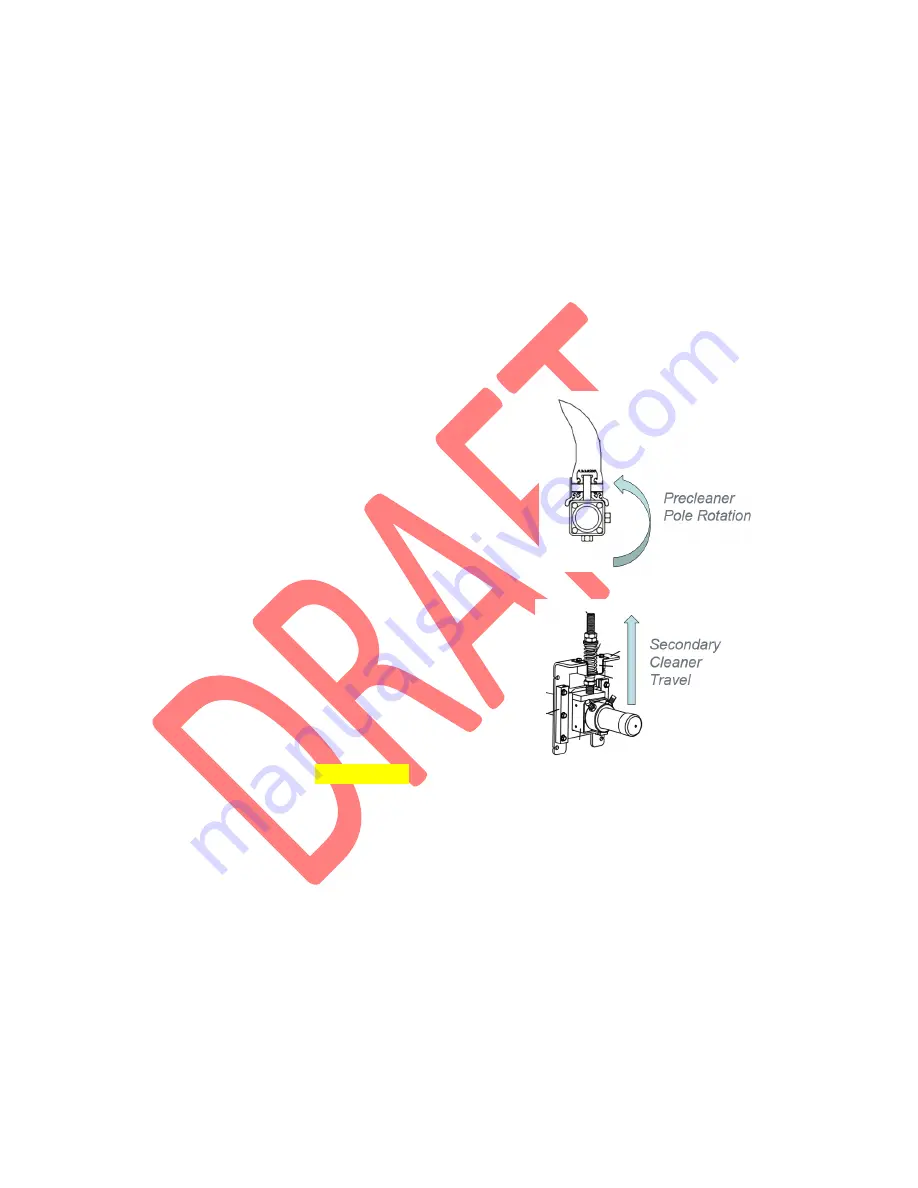

On precleaners, make sure you attach the device so it has enough room to turn

as the blade wears and the pole rotates

On secondary cleaners, make sure you attach the device so it has enough

vertical space to travel as the tips wear

o

Download the BRAND NAME mobile application

1.

Prepare the pole (optional)

. If using a pole extender, then push/hammer the extender into the pole

and turn the draw bolt to 80 in-lbs (9.0 Nm). If using a pole adapter, then slide the adapter over the

pole.

2.

Affix the device.

a.

Depending on the location of the device on the pole, slide the device onto the pole or

remove the top cap completely and reattach around the pole so the keypad faces forward.

Do not affix the device so the keypad faces the conveyor as this will inhibit your ability to

use the Bluetooth® wireless communication button, information button and LEDs for

routine maintenance.