17

U.S. patent No. 6.926.133

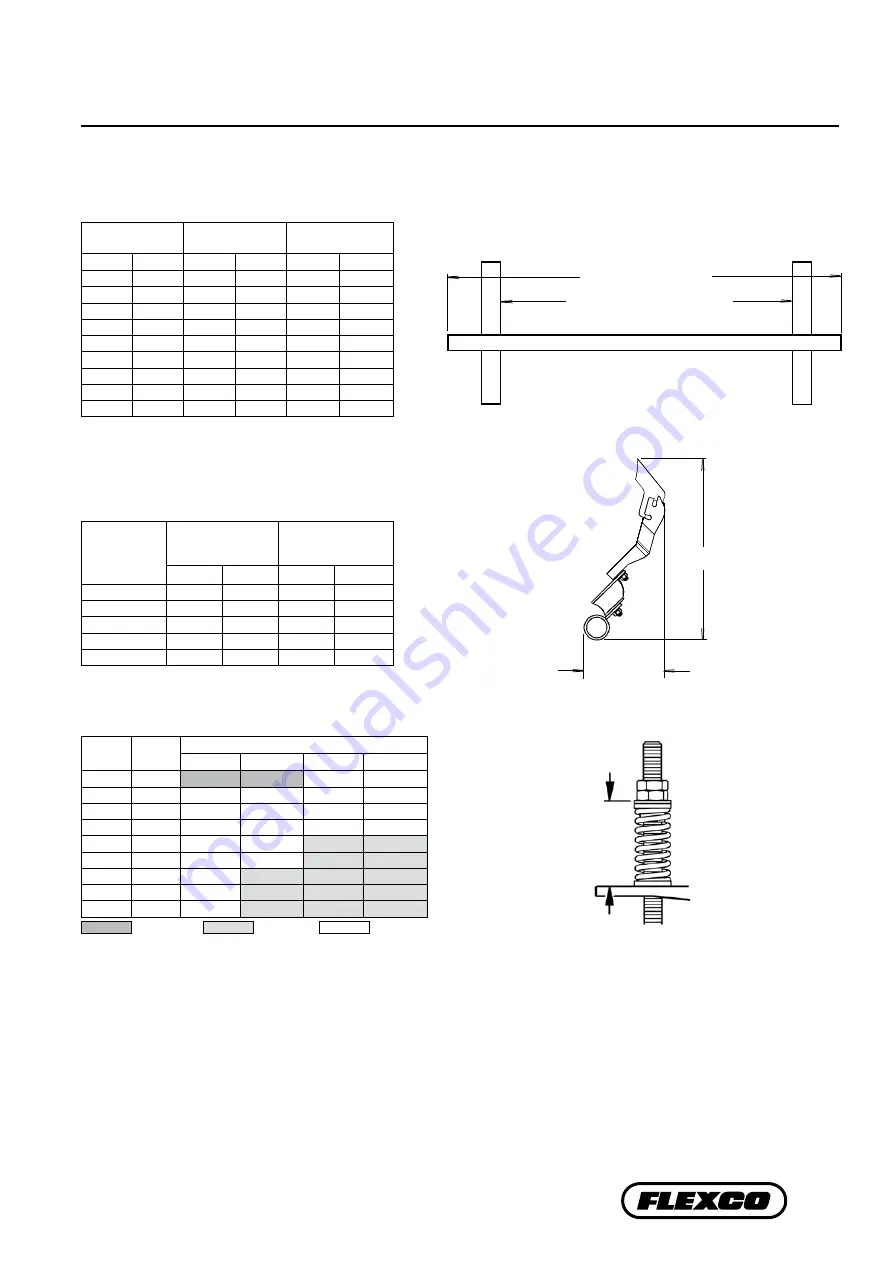

8.1 Specifications and Guidelines

Section 8 – Specs and CAD Drawings

Top of

washer

to top of

torque arm

Clearance Guidelines

for Installation

Suspension

Arm Size

Horizontal

Clearance

Required

Vertical

Clearance

Required

mm

in.

mm

in.

SS

175

7

325

13

S

175

7

375

15

M

175

7

413

16 1/2

L

175

7

463

18 1/2

LL

175

7

550

22

Pole Length Specifications*

Cleaner Size

Pole Length

Maximum

Conveyor Span

mm

in.

mm

in.

mm

in.

450

18

1650

66

1400

56

600

24

1800

72

1550

62

750

30

1950

78

1700

68

900

36

2100

84

1850

74

1050

42

2250

90

2000

80

1200

48

2400

96

2150

86

1350

54

2550

102

2300

92

1500

60

2700

108

2450

98

1800

72

3000

120

2750

110

*For special extra long pole length requirements a Pole Extender Kit

(#76024) is available that provides 750mm (30") of extended pole length.

Pole Diameter - 73mm (2-7/8")

HXF2 Spring Length Chart

(for optimal blade tensioning)

Belt

Width

Tips

Spring Length

SS

S

M

L

450

2

114

102

145

N/A

600

3

142

138

135

N/A

750

3

142

138

135

N/A

900

4

127

130

5"

109

1050

5

128

120

152

152

1200

5

128

120

152

152

1350

6

120

152

149

149

1500

7

N/A

149

145

145

1800

8

N/A

145

142

142

Purple Spring

Silver Spring

White Spring

Overall Pole Length

Maximum Conveyor Span

Specifications:

• Maximum Belt Speed ..........................................5M/sec (1000 FPM)

• Temperature Rating .............................................-35°C to 82°CF (-30°F to 180°)

• Usable Blade Wear Length ..................................75mm (3")

• Blade Material ...................................................... Urethane (proprietary blend for

abrasion resistance and long wear)

• Available for Belt Widths .................................... 450mm to 1800mm (18" to 72").

Other sizes available upon request.

Horizontal

Vertical