10

MHCP Primary Cleaner

Section 4 – Installation Instructions

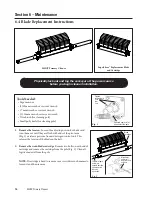

7. Centre the blades on the belt.

Slide the pole until the blades

are centreed or cover the belt’s

material path (Fig. 7). NOTE:

Standard blade coverage is

belt width minus 150mm. If

less blade coverage is required,

single blades can be removed

from the blade cartridge.

The blades do not have to be

centred in the cartridge. They

should be centred on the belt’s

material path.

8. Lock the extender poles in the centre pole. Tighten the two locking bolts and jam nuts on each end of the centre

pole (Fig. 8).

Install the tensioning system. For the PST Spring Tensioner go to step 9S. For the AWT Air/Water or PAT

Tensioner proceed to step 9A.

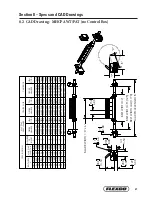

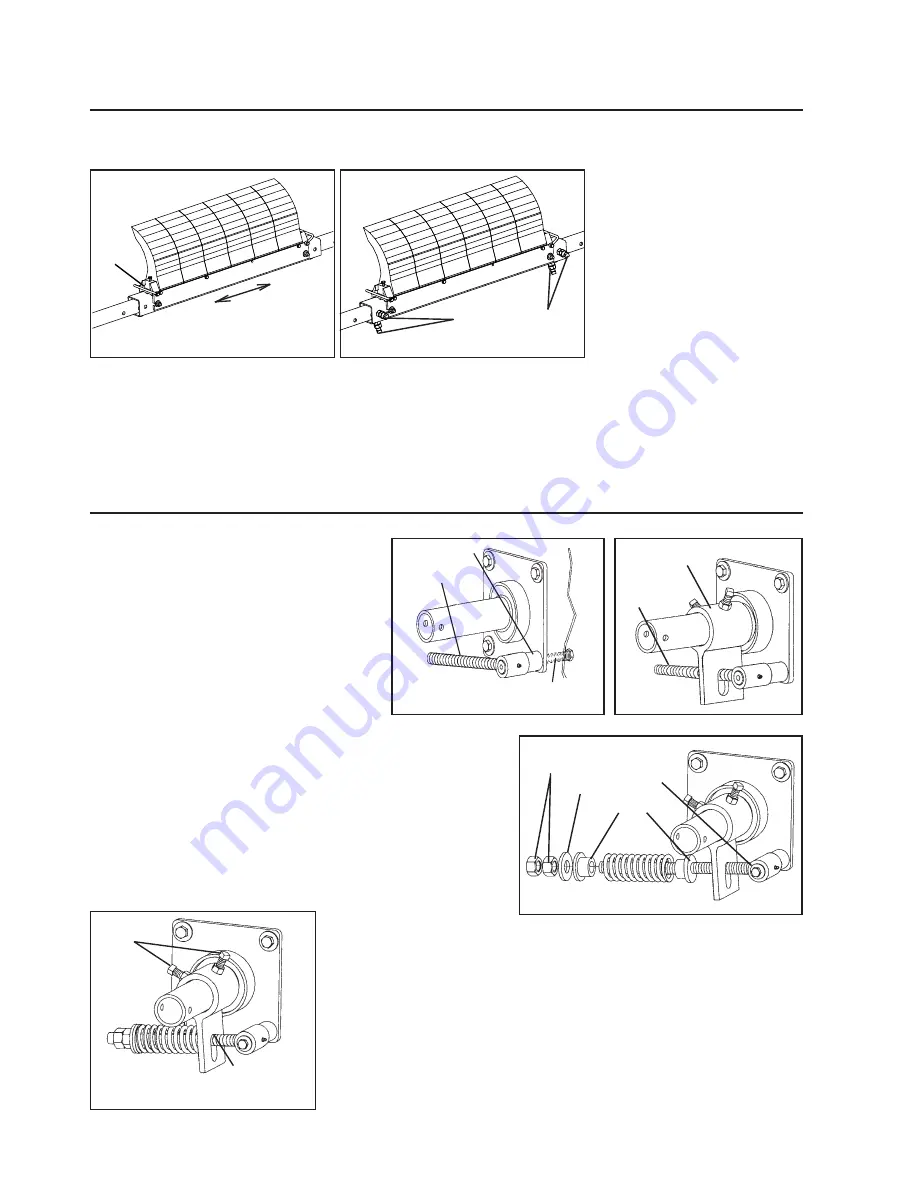

9S. Install the torque pivot rod. Remove the

adjusting nuts and springs from the rods.

The pivot rod base can be installed in any of

the four mounting plate holes. Determine

the rotation desired. Insert the pivot rod

mounting bolt through the chute wall and

the mounting plate and into the pivot rod

base and tighten (Fig. 9S).

10S. Slide the torque arm onto the pole end. Again ensuring the

correct pulling rotation, put the torque arm onto the pole end

and rotate it around until the torque pivot rod slides through

the slot (Fig. 10S).

11S. Reassemble the spring assembly. Slide the spring, washer and

bushings onto the pivot rod and turn the two adjusting nuts

so about 6mm of the rod is exposed above the nuts (Fig. 11S).

Complete steps 9S through 11S on the other side.

12S. Tension the blades to the belt. Rotate the blades until they contact the

belt. While holding the spring bushing flat on the torque arm, rotate the

torque arm until the pivot rod is against the end of the slot nearest the

pole. Tighten the locking bolts and jam nuts on the torque arm (Fig. 12S).

NOTE: The torque arm should be up against the mounting base.

Primary Cleaner Spring

Tensioner (PST)

4.1 MHCP Primary Cleaner (cont.)

Fig. 7

Fig. 8

Slide pole to center

blades or cover

belt’s material path

Remove

blade stop

to slide

blade(s)

off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 9S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 10S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 11S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 12S