11

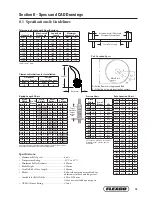

Pressure Chart

Blade

Width

No. of

Blades

kPa

mm

in.

450

18"

3

55.2

600

24"

4

69.0

750

30"

5

89.6

900

36"

6

103.4

1050

42"

7

124.1

1200

48"

8

137.9

1350

54"

9

158.6

1500

60"

10

172.4

1650

66"

11

193.1

1800

72"

12

213.7

1950

78"

12

227.5

2100

84"

14

248.2

2250

90"

15

262.0

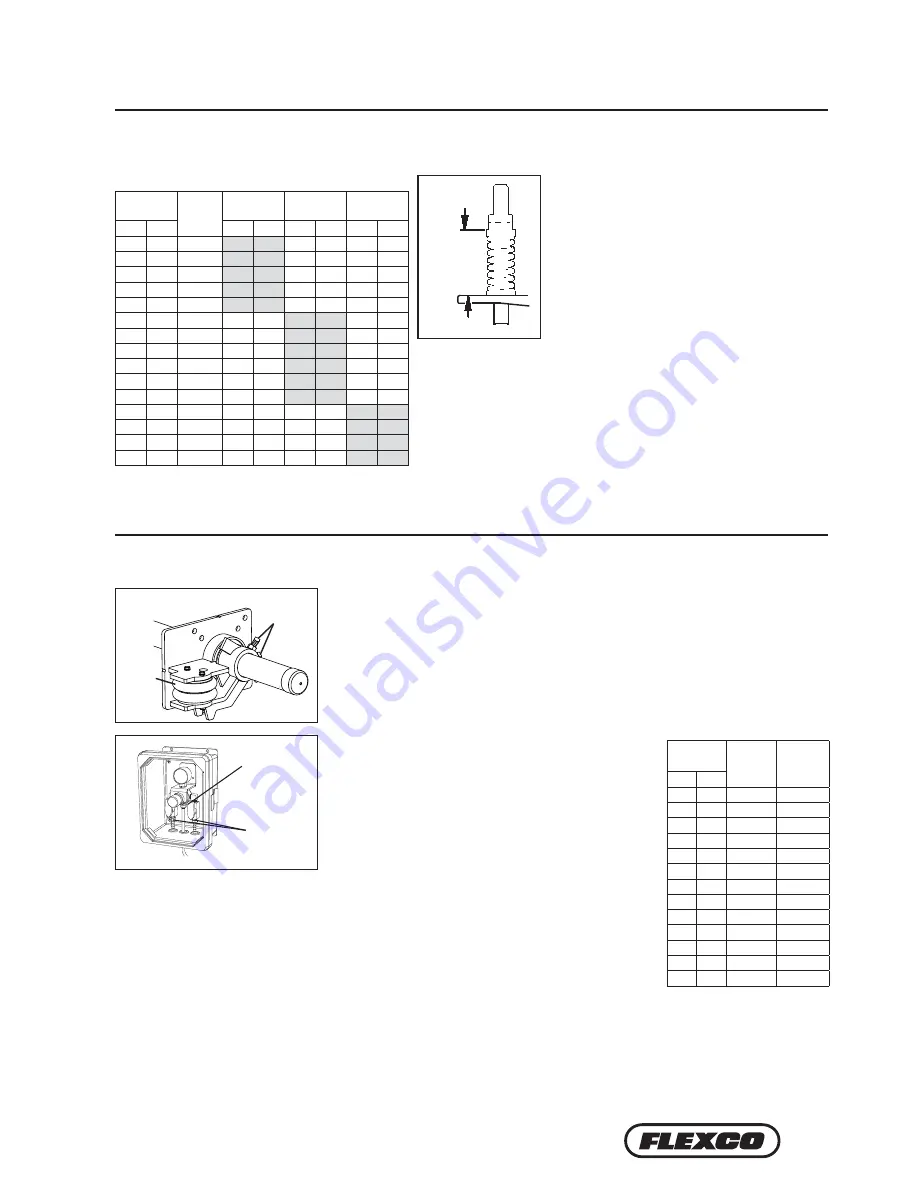

kPa setting is based on the number

of blades on the cleaner, not the

belt width.

Spring Length Chart

Blade

Width

No. Of

Blades

White

Springs

Silver

Springs

Red

Springs

mm

in.

mm

in.

mm

in.

mm

in.

450

18"

3

146

5 3/4"

162

6 3/8"

165

6 1/2"

600

24"

4

137

5 3/8"

159

6 1/4"

162

6 3/8"

750

30"

5

130

5 1/8"

156

6 1/8"

162

6 3/8"

900

36"

6

121

4 3/4"

156

6 1/8"

159

6 1/4"

1050

42"

7

114

4 1/2"

152

6"

159

6 1/4"

1200

48"

8

N/A

N/A

149

5 7/8"

156

6 1/8"

1350

54"

9

N/A

N/A

146

5 3/4"

156

6 1/8"

1500

60"

10

N/A

N/A

146

5 3/4"

152

6"

1650

66"

11

N/A

N/A

144

5 5/8"

152

6"

1800

72"

12

N/A

N/A

140

5 1/2"

149

5 7/8"

1950

78"

13

N/A

N/A

130

5 1/8"

146

5 3/4"

2100

84"

14

N/A

N/A

N/A

N/A

146

5 3/4"

2250

90"

15

N/A

N/A

N/A

N/A

144

5 5/8"

2400

96"

16

N/A

N/A

N/A

N/A

140

5 1/2"

2550

102"

17

N/A

N/A

N/A

N/A

140

5 1/2"

Spring tension is based on the number of blades on the

cleaner, not the belt width. Shading indicates preferred

spring option.

Section 4 – Installation Instructions

4.1 MHCP Primary Cleaner (cont.)

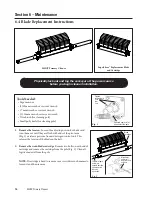

Fig. 13S

Locking Bolts

And Jam Nuts

Collapse

Air Bags

Connect lines

from air bags

Connect line

from site supply

Air/Water Control Box

Connect lines

from air bags

Connect line

from site

supply

Nitrogen Regulator

of Washer

orque Arm

Measure

from top

of washer

to top of

torque arm.

13S. Set the correct blade tension.

Refer to the

chart or the decal on the mounting base

for the spring length required for the belt

width. Lightly pull the pivot rod toward

the end of the torque arm slot nearest the

pole and turn the adjusting nuts until

the required spring length is achieved

(Fig.13S). Complete steps 12S and 13S on

the other side. For best results, recheck

the spring length on the first side to insure

there has been no movement.

14S. Test run the cleaner.

Run the conveyor for at least 15 minutes and

inspect cleaning performance. Check the spring lengths for proper

tensioning. Make adjustments as necessary.

NOTE:

Tensioners are shipped with the air bags and torque arms attached to the

mounting bases.

9P. Tension the blades to the belt.

Collapse both air bags (with C-clamps) and rotate

the blades until they are 25mm short of contact with the belt. Tighten the torque

arm locking bolts and jam nuts (Fig. 9P).

10P. Connect the supply lines and set tension pressure.

With the parts supplied, attach a line to each air

bag and run the lines to the outlet side of the PAT

control box (Fig. 10P).

NOTE:

Be sure lines are

safely away from the belt. Connect a line from the

inlet side of the box to the site’s supply or air tank.

Test the connections for leaks and set the pressure

per the chart on the control box (also shown below).

Take the pressure chart label from the instruction

packet and affix it in an easily accessible location

near the regulator for future reference.

11P. Test run the cleaner.

Run the conveyor for at least 15 minutes and inspect cleaning

performance. Make adjustments as necessary.

Portable Air Tensioner (PAT)

Connect line

from site supply

or tank

Connect lines

from air bags

Fig. 10P

PAT Control Box

Fig. 9P

Collapse

air bags

Locking bolts

and jam nuts