19

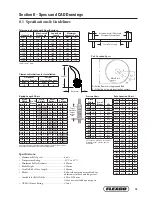

8.1 Specifications & Guidelines

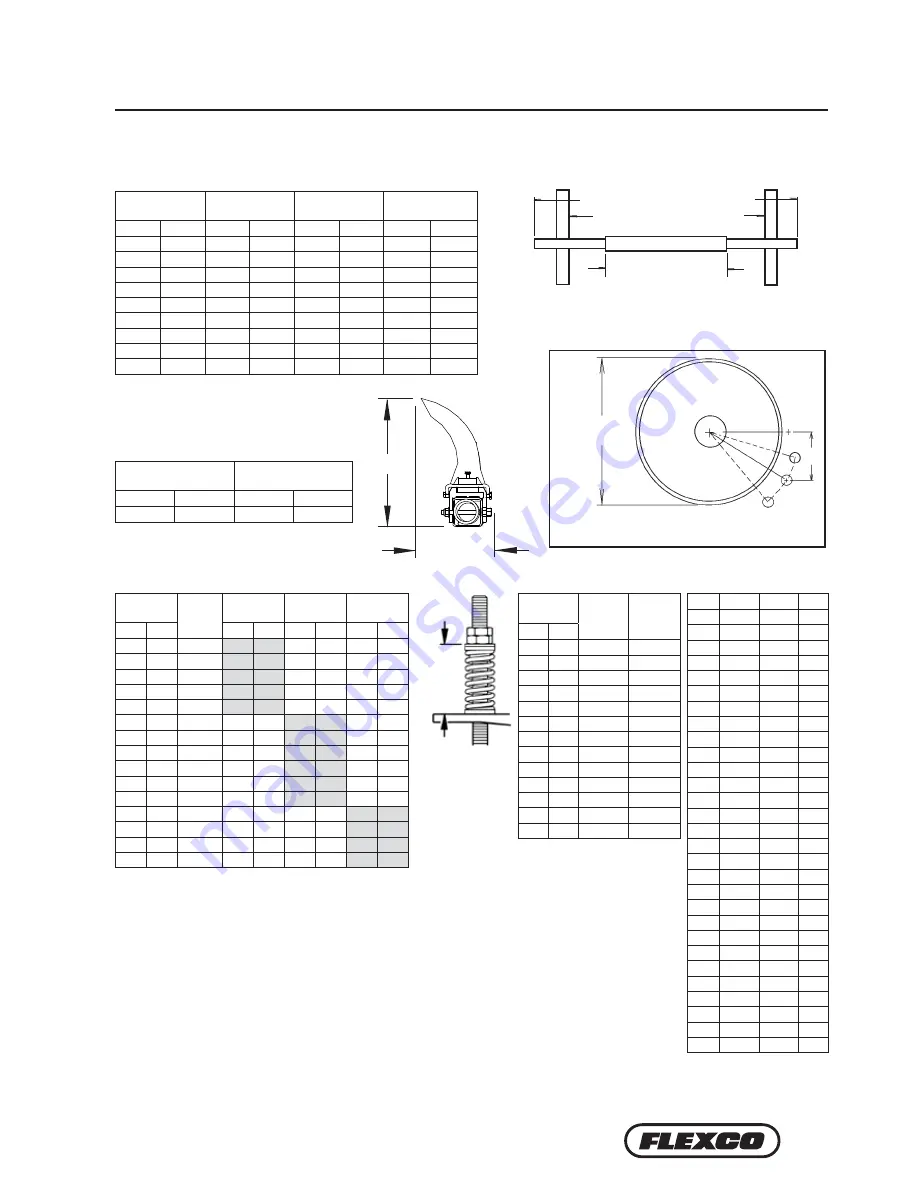

Clearance Guidelines for Installation

Horizontal

Clearance Required

Vertical

Clearance Required

mm

in.

mm

in.

175

7

475

19

Telescoping Pole Length Specifications

Cleaner Size

Max Overall

Pole Length

Centre Pole

Length

Maximum

Conveyor Span

mm

in.

mm

in.

mm

in.

mm

in.

600

24

2050

82

700

28

1650

66

750

30

2200

88

850

34

1800

72

900

36

2350

94

1000

40

1950

78

1050

42

2500

100

1150

46

2100

84

1200

48

2650

106

1300

52

2250

90

1350

54

2800

112

1450

58

2400

96

1500

60

2950

118

1600

64

2550

102

1800

72

3250

130

1900

76

2850

114

2100

84

3550

142

2200

88

3150

126

Pole Diameter - 73mm

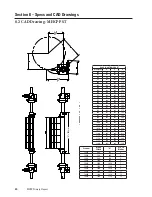

Pole Location Chart

A

X

Y

C

500

254

365

445

525

267

365

451

550

279

365

460

575

292

365

467

600

305

365

476

625

318

365

483

650

330

365

492

675

343

365

502

700

356

365

511

725

368

365

518

750

381

365

527

775

394

365

537

800

406

365

546

825

419

365

556

850

432

365

565

875

445

365

575

900

457

365

584

925

470

365

594

950

483

365

606

975

495

365

616

1000

508

365

625

1025

521

365

635

1050

533

365

648

1075

546

365

657

1100

565

365

673

1125

581

365

686

1150

597

365

699

1175

610

365

711

1200

625

365

724

Specifications:

• Maximum Belt Speed ..........................................6 m/s

• Temperature Rating .............................................-35°C to 82°C

• Minimum Pulley Diameter ................................500 mm

• Blade Height .........................................................350 mm

• Useable Blade Wear Length ................................200 mm

• Blades .................................................................... Polyurethane (proprietary blend for

abrasion resistance and long wear).

• Available for Belt Widths .................................... 600 to 2100 mm

Other sizes available upon request.

• CEMA Cleaner Rating ........................................Class 5

Maximum Overall Pole Length

Maximum Conveyor Span

Centre Pole Length

Top of

washer to

top of

torque

arm

Pole Location Specs

A = Pulley Di Lagging and Belt

C = Critical Spec to move location if necessary

A

X

C

Y

Move Dim. C

on arc

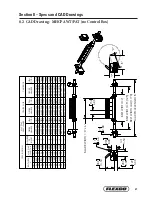

Section 8 – Specs and CAD Drawings

Vertical

Horizontal

Spring Length Chart

Blade

Width

No. Of

Blades

White

Springs

Silver

Springs

Red

Springs

mm

in.

mm

in.

mm

in.

mm

in.

450

18"

3

146

5 3/4"

162

6 3/8"

165

6 1/2"

600

24"

4

137

5 3/8"

159

6 1/4"

162

6 3/8"

750

30"

5

130

5 1/8"

156

6 1/8"

162

6 3/8"

900

36"

6

121

4 3/4"

156

6 1/8"

159

6 1/4"

1050

42"

7

114

4 1/2"

152

6"

159

6 1/4"

1200

48"

8

N/A

N/A

149

5 7/8"

156

6 1/8"

1350

54"

9

N/A

N/A

146

5 3/4"

156

6 1/8"

1500

60"

10

N/A

N/A

146

5 3/4"

152

6"

1650

66"

11

N/A

N/A

144

5 5/8"

152

6"

1800

72"

12

N/A

N/A

140

5 1/2"

149

5 7/8"

1950

78"

13

N/A

N/A

130

5 1/8"

146

5 3/4"

2100

84"

14

N/A

N/A

N/A

N/A

146

5 3/4"

2250

90"

15

N/A

N/A

N/A

N/A

144

5 5/8"

2400

96"

16

N/A

N/A

N/A

N/A

140

5 1/2"

2550

102"

17

N/A

N/A

N/A

N/A

140

5 1/2"

Spring tension is based on the number of blades on the cleaner, not the

belt width. Shading indicates preferred spring option.

Pressure Chart

Blade

Width

No. of

Blades

kPa

mm

in.

450

18"

3

55.2

600

24"

4

69.0

750

30"

5

89.6

900

36"

6

103.4

1050

42"

7

124.1

1200

48"

8

137.9

1350

54"

9

158.6

1500

60"

10

172.4

1650

66"

11

193.1

1800

72"

12

213.7

1950

78"

12

227.5

2100

84"

14

248.2

2250

90"

15

262.0

kPa setting is based on the number

of blades on the cleaner, not the

belt width.