22

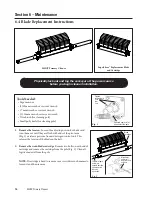

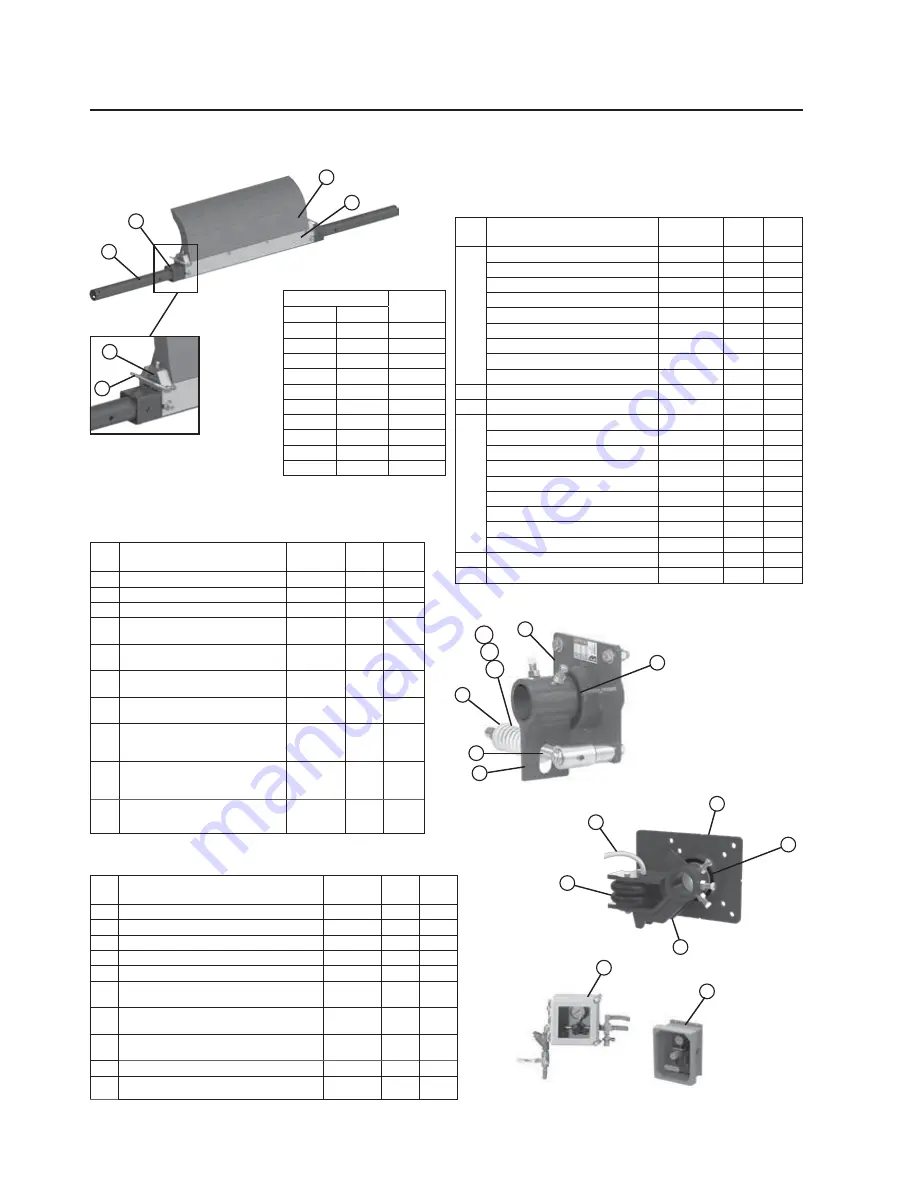

MHCP Primary Cleaner

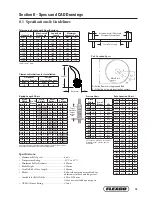

9.1 Replacement Parts List

Section 9 – Replacement Parts

Replacement Parts

Ref Description

Ordering

Number

Item

Code

Wt.

Kg.

1

600 mm Centre Pole*

MHP-CP24

75961

8.6

750 mm Centre Pole*

MHP-CP30

75962

10.5

900 mm Centre Pole*

MHP-CP36

75963

12.3

1050 mm Centre Pole*

MHP-CP42

75964

14.2

1200 mm Centre Pole*

MHP-CP48

75965

16.0

1350 mm Centre Pole*

MHP-CP54

75966

17.9

1500 mm Centre Pole*

MHP-CP60

75967

19.7

1800 mm Centre Pole*

MHP-CP72

75968

23.4

2100 mm Centre Pole*

MHP-CP84

76811

27.3

2

MHCP Extender Poles (2 ea.)

MHP-EP

76392

24.5

3

SuperShear™ Blade

SSRB

75978

3.0

4

600 mm 2-Piece Blade Cartridge*

MHCP-2BC24

76638

6.0

750 mm 2-Piece Blade Cartridge*

MHCP-2BC30

76639

8.0

900 mm 2-Piece Blade Cartridge*

MHCP-2BC36

76640

10.0

1050 mm 2-Piece Blade Cartridge*

MHCP-2BC42

76641

12.0

1200 mm 2-Piece Blade Cartridge*

MHCP-2BC48

76642

14.0

1350 mm 2-Piece Blade Cartridge*

MHCP-2BC54

76643

16.0

1500 mm 2-Piece Blade Cartridge*

MHCP-2BC60

76644

18.0

1800 mm 2-Piece Blade Cartridge*

MHCP-2BC72

76645

22.0

2100 mm 2 -Piece Blade Cartridge*

MHCP-2BC84

76812

25.6

5

MHCP Cartridge Handle*

MHCP-CH

76393

0.2

6

MHCP Cartridge Blade Stop*

MHCP-BS

76394

0.2

*Hardware Included

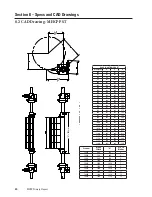

PST Spring Tensioner Replacement Parts

Ref Description

Ordering

Number

Item

Code

Wt.

Kg.

7

Mounting Base* (1 ea.)

PMB

75895

10.1

8

Torque Arm* (1 ea.)

PSTA

75896

5.2

9

Torque Pivot Kit (1 ea.) (no spring)

PTPK

75897

3.2

10

Tension Spring - White (1 ea.)

for belts 600-1200mm

PSTS-W

75898

0.8

10a Tension Spring - Silver (1 ea.)

for belts 1350-2100mm

PSTS-S

75899

1.4

11

Bushing Kit (2 ea.) (for White & Silver

Tensioners)

QMTBK-W

76098

0.1

12

Pole Bearing Assy (for cleaners shipped

after 4/2016)

AWTPBA

90000

0.3

–

PST Spring Tensioner* - White

(includes 2 each items 7, 8, 9, 10 & 11)

for belts 600-1200mm

PST-W

75893

39.1

–

PST Spring Tensioner* - Silver

(includes 2 each items 7, 8, 9, 10a & 11)

for belts 1350-2100mm

PST-S

75894

39.1

-

PST Spring Tensioner* - Red

(incl. 2 each items 7, 8, 9 ,10b &11

for belts 2400mm

PST-R

77725

39.1

*Hardware Included

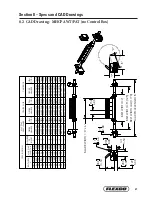

Air/Water & Nitrogen Tensioner Replacement Parts

Ref Description

Ordering

Number

Item

Code

Wt.

Kg.

13

Air/Water Bag

(1 ea.)

AWTB

75905

1.7

14

Mounting Base

(1 ea.)

AWTMB

75906

10.4

15

Torque Arm*

(1 ea.)

AWTA

75907

5.3

16

Hose Kit

(50' of hose and 6 hose clamps)

AWTHK

75909

3.0

17

Control Box

(Complete)

AWTCB

75908

2.0

–

AWT Air/Water Tensioner

(includes 2 each items 13,

14, & 15 and 1 each items 16 & 17)

AWT

75904

39.1

–

AWT Air/Water Tensioner w/o Control Box

(includes 2 each items 13, 14, 15 & 1 each item 16)

AWTNCB

76069

34.1

–

AWT Air/Water Tensioner w/o Control Box, 1 side

(includes 1 each items 13, 14, 15 & 16)

AWT-1S

76375

17.1

18

PAT Control Box

PACB

78683

5.0

–

PAT Kit- AWT Tensioner w/ Control Box

(includes 2

ea. Items 13,14, 15, 16 & 1 ea. Item 18)

PAK

78705

39.1

*Hardware Included

17

2

1

3

4

5

6

Blades Required

per Belt Width

Belt Width

Blades

Required

mm

in.

600

24

3

750

30

4

900

36

5

1050

42

6

1200

48

7

1350

54

8

1500

60

9

1800

72

11

2100

84

13

2400

96

15

Blades and cartridges can be purchased

separately (see chart at right) or

preassembled as a Blade Cartridge Kit.

18

10

7

9

8

11

12

10a

10b

12

13

14

15

16